Piezo Sensing

Piezo Sensing records:

96,000

–samples– per second

Piezo Sensing, part of the SMARTsensing suite of hardware products, expands the already robust capabilities of the KCF Technologies Comprehensive Machine Health Platform.

Large, slow rotating equipment and high speed applications, such as paper machines, can often present challenges when monitoring using traditional methods. When equipment moves slower, advanced methods are needed to accurately track and prevent machine failures. Piezo Sensing solves this problem by using advanced enveloping technology – a processing method that isolates and highlights impacts, making accurate detection possible – Piezo Sensing enables you to monitor your most critical equipment, regardless of speed all within one platform.

Piezo Sensing’s emphasis on data quality allows earlier identification of faults than other platforms support and enables monitoring for high-speed application that other solutions can’t address.Use Cases:

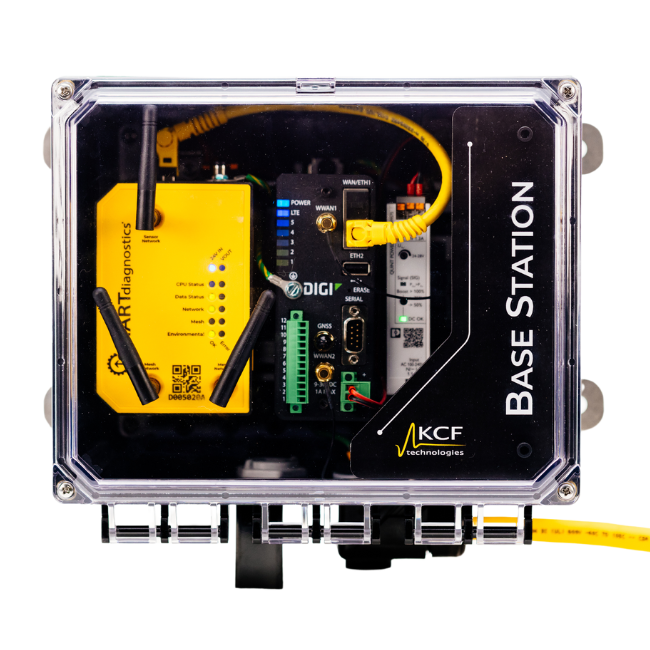

Piezo Sensing Predictive Maintenance Hardware

Industry Use Cases

General

- Gearboxes

- Mixers

- Steam Turbines

- Gas Turbines

Energy

- Gas / Steam turbines

- Reciprocating compressors / piping

Paper

- Dryer Section

- Press / felt rolls

- Lime Kiln

- Wash Press

- Pulp Mill agitator

- Winder / de winder

- Top separator

- High pressure feeder

- Refiner

Automotive

- Stamping Press Crowns

- Battery Mixers

Mining

- Ball Mill Pinion and Bearing Monitoring

Glass

- Bearings on annealing, inspection, cutting stages

Metals

- Hot/Cold rolling

- Blast furnace monitoring

- Electric arc furnace monitoring

- Continuous caster bearings

Hourly full-spectrum readings enable Stage 1 Fault Detection, allowing for the identification of bearing faults when 50% of their lifespan remains.

Key Features

Enhanced Bearing Fault Detection with

Enveloping

Without the right solution, picking up the minute, high frequency impacts arising from bearing wear can be difficult to detect. Piezo Sensing isolates and highlights high-frequency components for superior bearing fault detection.

By leveraging advanced high frequency enveloping, Piezo Sensing excels in isolating and accentuating even the most subtle impacts caused by bearing wear. This capability is crucial, as without the right technology, these minute yet critical symptoms can easily go unnoticed. Piezo Sensing’s implementation of enveloping ensures that these signals are captured consistently and reliably. Providing unparalleled precision in bearing fault detection and ensuring the reliability and longevity of your equipment.

Ideal for Slow-Rotating Equipment & High Speed Applications

With its exceptional high-speed sampling capabilities, Piezo Sensing records 96,000 samples per second, ensuring the precise detection of even the subtlest bearing faults. This, combined with its ability to support extended sampling durations, makes Piezo Sensing uniquely adept at monitoring equipment operating at ultra-low speeds, down to 2 RPM. Such comprehensive coverage ensures that even the earliest signs of potential issues are captured, facilitating timely intervention, and preventing minor faults from escalating into major failures.

Check Out All Our Machine Health Hardware

Contact Us Today