Pressure Sensor

Pressure Sensing is one of the many capabilities seamlessly integrated into KCF’s Comprehensive Machine Health Monitoring Platform.

Gain the ability to see real time pressure data, right alongside vibration and temperature data in one easy-to-use platform. This capability within the product family unlocks the ability to detect and proactively correct problems such as clogged filters, air/gas leaks, improper configuration, among others, all through a single vendor, eliminating costly time-based maintenance protocols.

KCF Technologies offers both –Differential– and –Absolute– pressure sensors, each with their own unique use cases.

Differential and Absolute Pressure Sensors

Differential Pressure Sensors

Used to measure the difference in pressure between two points in a system at a very precise level. They are best suited for systems where measurements of small pressure differences are needed.

- Filter clogging

- Air/gas leaks

- Dampers/valves friction losses

- Fan/pump efficiency

Absolute Pressure Sensors

Measure the pressure at a single point in a system, and are available in a wide range of sensitivities for various systems. Issues that can be diagnosed using Absolute Pressure sensors include:

- Pump cavitation

- Pump efficiency

- Impeller

- Filter/screen clogging

- Compressed air/gas leaks

- Valves/heat exchangers friction losses

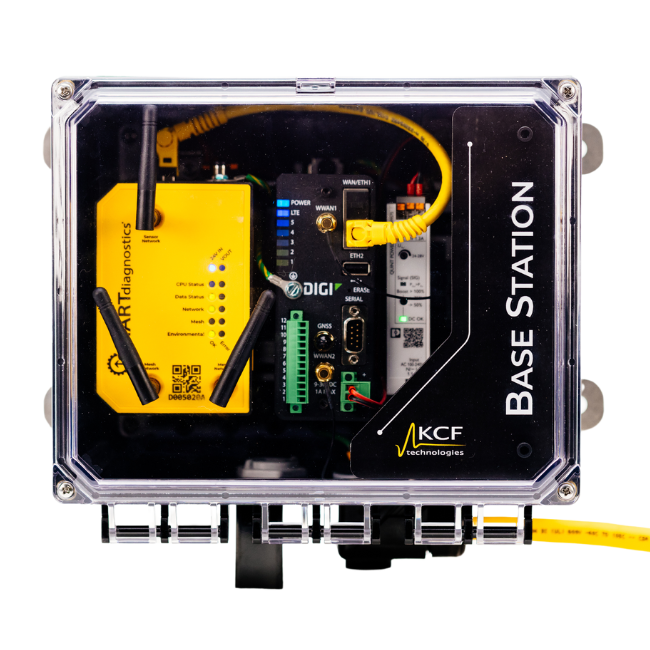

Pressure Sensors require a KCF Technologies IoT HUB and analog adapter for use.

The SMARTdiagnostics IOT HUB is the next generation of full asset health solutions designed to handle the most complex asset monitoring needs. Including: triggered collections, multi-functional sensor ports, and the ability to withstand higher temperatures with external power sourcing, with optional wired power solution.

Check Out All Our Machine Health Hardware

Contact Us Today