RYAM & KCF Technologies

Moving Equipment into a Precise State

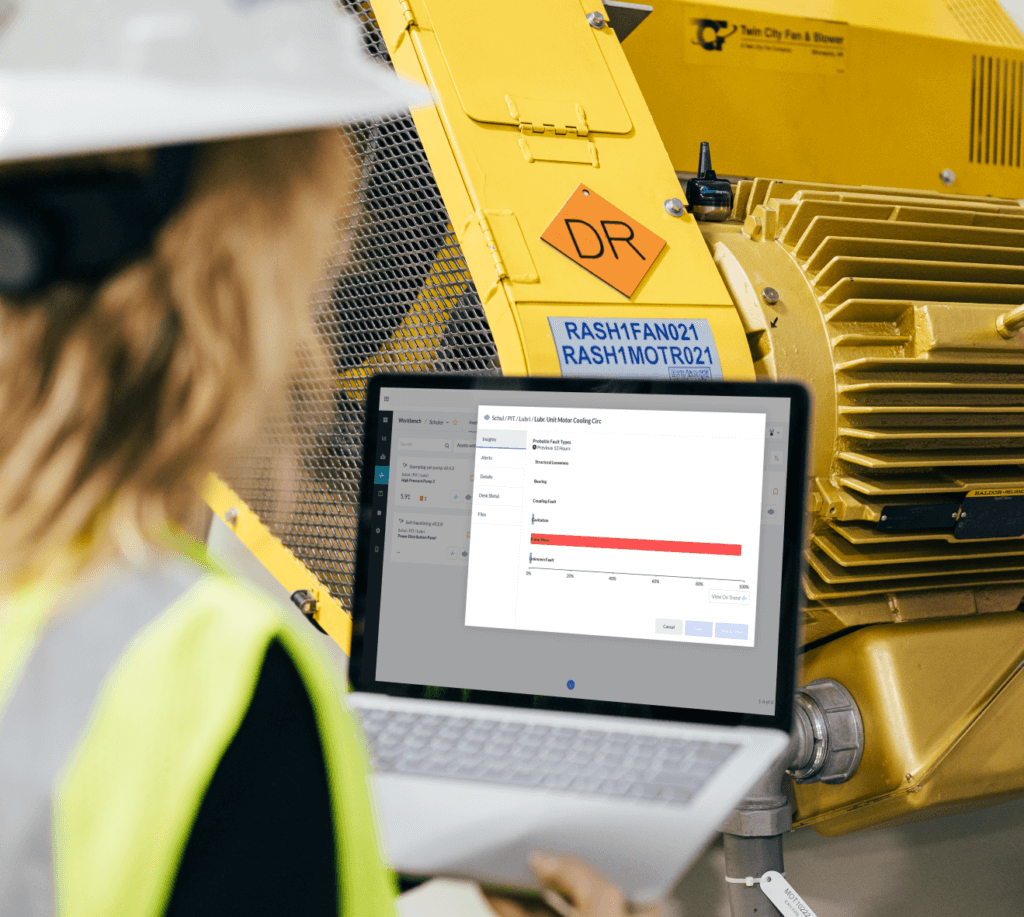

Discover RYAM’s transformative journey with KCF Technologies, enhancing equipment reliability and safety across all manufacturing facilities. Since 2021, RYAM has installed over 2,600 KCF sensors in Jessup, Georgia, achieving 95% coverage of critical machinery. This adoption of KCF’s 24/7 monitoring technology minimizes routine checks, averts failures, and boosts efficiency. The initiative demonstrates RYAM’s dedication to innovation, equipment longevity, and environmental sustainability in the industrial sector.

Case Studies

THE MACHINE HEALTH PROBLEM & REACTIVE MAINTENANCE PRACTICES IS A HUGE PROBLEM.

FEATURED IN PROCESS INDUSTRY INFORMER.

Contrary to intuition, machine health degradation is not the machine problem. From observations gleaned from over 700 manufacturing locations and over 135,000 assets, KCF Technologies found that only about 20% of machine degradation comes from normal wear and tear. This means that the other 80% is inflicted by something unexpected.

Machine Health Stories

Dr. Jeffrey Liker, University of Michigan, Liker Lean Advisors

Joe Li, Manager, Toyota North America

Yahya Khan, Senior Reliability Engineer, Clarios Corporation

Dr. Jeremy Frank, CEO and Founder, KCF Technologies, Inc.

Lean and Digital Manufacturing

Putting People at the Center

This feature article jointly written by Dr. Jeff Liker – Author of the Toyota Way, Dr. Jeremy Frank-CEO of KCF Technologies, Yahya Kahn – Regional Reliability Leader at Clarios, and Joe Li – Manager at Toyota dives into the transition from the lean movement and the technology advancements of Industry 4.0.

Readers will learn about the limitations of relying solely on automated systems for problem-solving, highlighting the enduring need for human intervention and adaptive problem-solving skills, especially as technologies evolve and more complex issues arise.

Insights from the authors illustrate the balance between predictive and adaptive problem-solving with the recommendation that manufacturing companies focus on developing the problem-solving abilities while integrating advanced digital technologies. This balanced approach, leads to more sustainable benefits and prepares for an industrial future where human intellect complements technological advancements.

Machine Health at Scale

Georgia Pacific and KCF Technologies

Experience the predictive machine health transformation of Georgia Pacific, a global leader in forest product manufacturing, as they optimize their operations -scaling from 20,000 to over 60,000 KCF Technologies sensors in just five years. Discover how this monumental scaling endeavor has revolutionized their business, slashing unplanned events by a jaw-dropping 50%, resolving systemic issues company-wide, and empowering every individual, regardless of position, with invaluable machine health data.

Empowering People with Technology

St. Croix Tissue and The University of Maine

“Investing in our program is one of the ways you end up with someone like Matt Cowen coming in to give a presentation to students, having a student. Alex Daigle, who’s sitting in that audience, then goes to work for your company, St. Croix Tissue, and brings this technology to fruition in less than a year after graduation and really makes a huge impact on your business.”

Carrie Enos

President of the Paper and Pulp Foundation

University of Maine

Why KCF

Over 700+ Manufacturing locations trust KCF Technologies

with their Asset Monitoring.

Why?

Because they are gaining a competitive edge.

An average of 10x ROI.

Introducing the Smartsensing Mobile Kit

Gain the flexibility of the KCF Technologies Comprehensive Machine Health Platform with a kit designed with flexibility in mind. Each mobile kit includes everything to get started with basic monitoring of an asset.

Each kit includes:

- 6 High-Definition Wireless Vibration Sensors

- 1 Base Station Gateway

- Access to SMARTdiagnostics software

- Access to KCF Academy

Get started today.

2024 Summit Keynotes

The 2024 Manufacturing the Future Summit was a monumental success! We’re thrilled to announce that our keynote speeches are now available virtually.

Hear from industry leaders on topics such as:

- Journey to Predictive Maintenance

- Steel Industry Evolution & Transformation

- Renewable Power & Reliable Maintenance

- and more