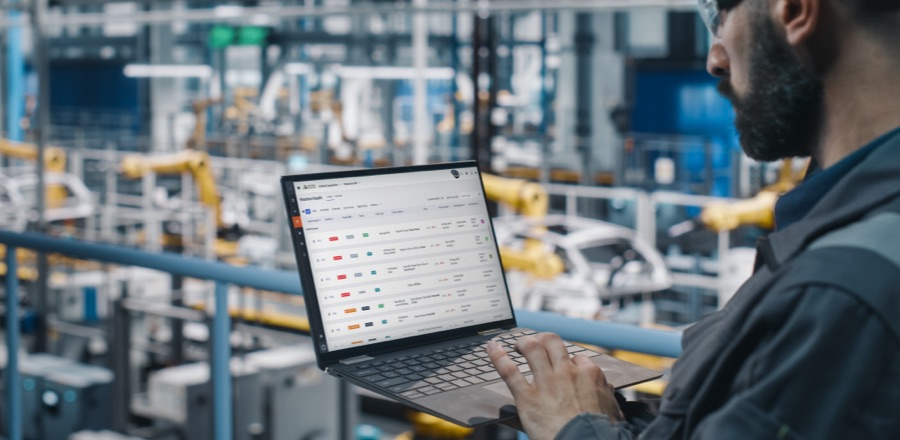

AI Predictive Maintenance for Machine Health

We empower industrial businesses with the most comprehensive predictive maintenance platform, combining highly accurate sensors, powerful AI software, and a team of experts to help your business thrive.

Move beyond reactive

1,000+

Over 1,000+ manufacturing locations trust KCF Technologies with their Asset Monitoring.

10x

These manufacturers are gaining a competitive edge and on average a 10x ROI with KCF Technologies.

Take control of your

plant’s performance

Eliminate

Systemic causes of failure

Reduce

Capital spend & maintenance costs

Extend

Asset and component life

Improve

Uptime and OEE

Achieve

10X return on investment

Gain

Total visibility into machine health

Start with a trial. See the proof.

Take the first step toward predictive maintenance with KCF’s risk-free $199 Trial Program. Get hands-on with our full predictive maintenance platform—sensors, real-time analytics, and expert support—designed to deliver immediate insights and early fault detection. No long-term contract. No pressure. Just real data, real savings, and a clear path to scale.

What if you could detect failures before they happen?

SMARTdiagnostics continuously tracks critical asset health, detecting early signs of faults and delivering real-time notifications—so you can take action before costly breakdowns occur.

How much is unplanned downtime costing you?

How much will you save with KCF Technologies? Use our Value Calculator to reveal the significant time and cost savings you can achieve with our comprehensive predictive maintenance platform.

Trusted by leading manufacturers

Gain a competitive edge with KCF

Customer Success Story

"By having these KCF sensors, we are able to detect when vibrations get out of the norm. We can investigate it and reduce or prevent catastrophic failure."

Leif Christensen, VP of Maintenance

Signal Peak Silica

Signal Peak Silica

Customer Success Story

"At Georgia Pacific we've had KCF sensors in our sites since 2018. we went from 100 sensors in 2018 to maybe 20,000 sensors in 2020. Now, five years later, we have about 62,000 sensors."

Moe Farhat, CSC Mechanical Asset Health

Georgia-Pacific

Georgia-Pacific

Customer Success Story

"Once you get those couple of big wins and people start to see a fault within the system and then they go out and they actually see in real life that what they saw on the sensor correlates to what they found on the equipment, suddenly it clicks to them—okay, there’s value."

Jared Stephens, Reliability Manager

Guardian Glass

Guardian Glass

"Since deploying KCF Technologies, our reactive maintenance on bearing faults has been reduced by 75%. This makes our facilities safer and more profitable."

James Harman, Chief Executive Officer

EDL Energy

EDL Energy

Customer Success Story

"Within the first two weeks of getting the sensors on site, KCF, they found a fault in one of our motors for our dryer, and it was an over -greasing situation. That one fault that was found saved us over $15,000. Saving that motor, just the motor, saved weeks and maybe months of downtime, and saved people going into a confined space."

Jon Driscoll, Information Technology Coordinator

Altoona Water

Altoona Water

Customer Success Story

"Our maintenance SOAR folks have found a great partnership with KCF."

Susann Kazunas, President

Toyota

Toyota

Industry Insights

"80% of the root causes that degrade machinery are avoidable: improper operating conditions, improper maintenance, and poor system configuration. These problems are all proactively solvable. You just need to deploy the right comprehensive machine health platform, get the right data, do the right analysis, and take the right action."

Jeremy Frank, Co-Founder and CEO

KCF Technologies

KCF Technologies

Request a demo

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.