Prabhu Ramachandran

Digital Transformation Project Manager

Kaneka

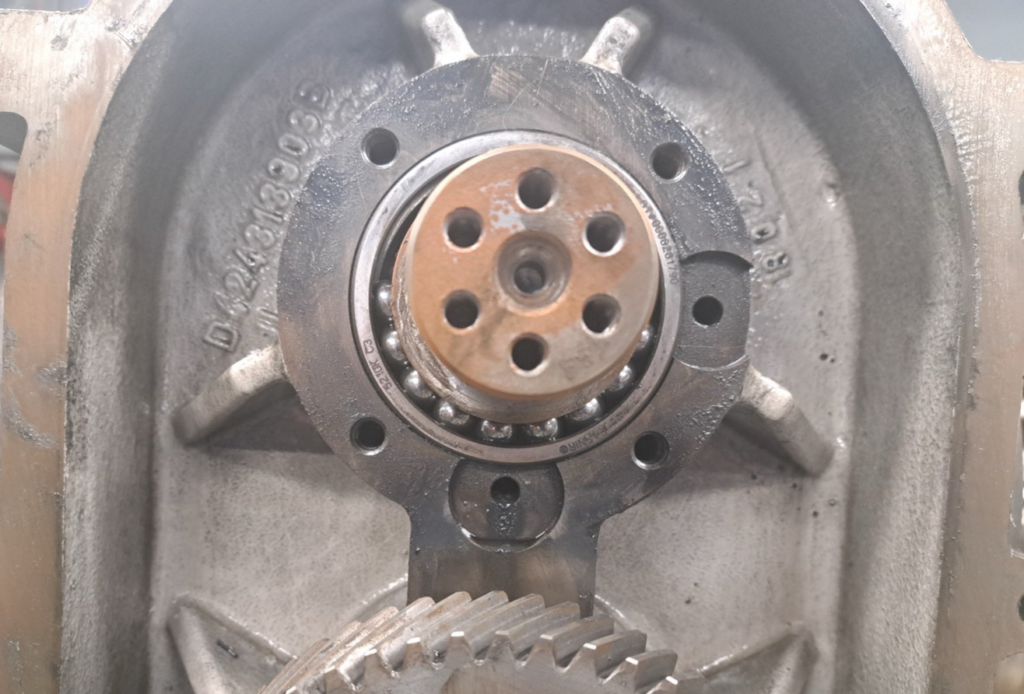

Vacuum Pumps

Vacuum pumps are critical in many manufacturing processes. KCF's comprehensive machine health monitoring empowers you with the data and insights needed to minimizing unplanned downtime.