Cost of Asset Failures

$5,000 / hour

DOWNTIME COST

>12 hours

DOWNTIME SAFETY RELATED COSTS

Industry Savings Potential

~$60,000

IN NPT

$85,000

REPLACEMENT PER MOTOR

>$145,000

IN TOTAL SAVINGS

Asset Blind Spots:

There are several inherent challenges related to monitoring Traction Motors:

CHALLENGE #1

Electrical & mechanical faults tend to go unaddressed until failure due to the nature of drilling rig operations. The Top Drive remains in continuous operation & in an elevated position. .

CHALLENGE #2

Frequent thorough inspection of internals is not a possibility due to complexity of the machine & continuous operations.

CHALLENGE #3

Time-based protocols do not allow for constant monitoring of mechanical & lubrication systems.

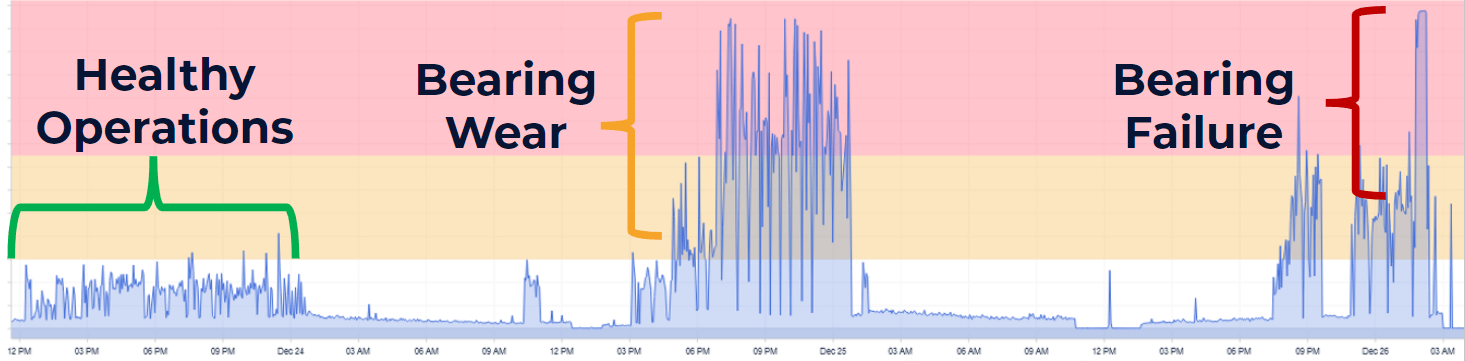

Top Drive Traction Motor Peak Acceleration

Historically drilling equipment has been run to failure. This methodology maximizes the life span of the equipment, but at the cost of additional risk to incurring NPT hours and imposing safety hazards on the rig crew.

Continuous Vibration health monitoring can help optimize mechanic and electrician deployment, maintenance routines, preparedness for replacement, & mitigating potential safety incidents. Additionally, it also opens potential opportunities for studies to extend Top Drive life & optimize field operations.

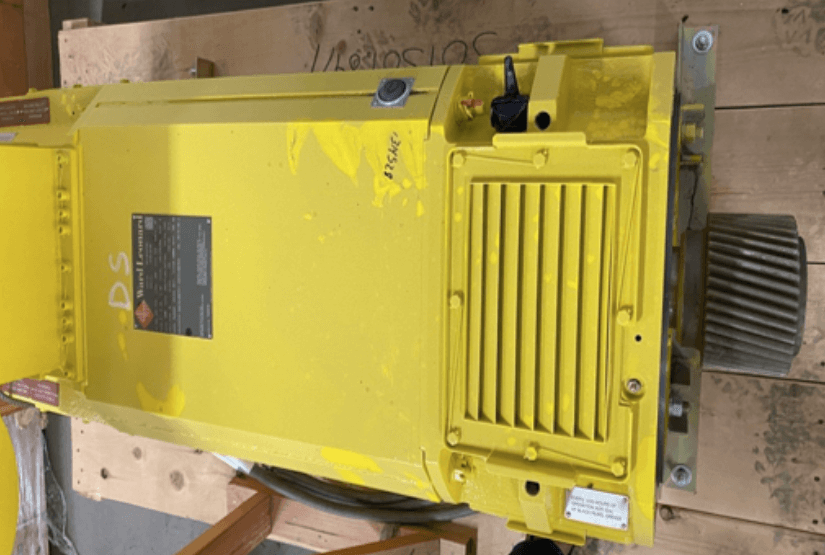

Hardware

- Two V3 vibration sensors per traction motor

- One on the inboard & one on the outboard ends of the traction motor

Software

- Threshold Settings

- Indicators

- Sensor Configurations

- Dashboards

- Reporting

Real-Time Data

- Electronic Drilling Recorder (EDR) is recommended, but not required

• Top Drive RPM

• Torque generate - Schematics of the Top Drive assembly are beneficial documents for detailed analysis

Training

- Sentry

• Site visits: bi-weekly

• In-person training - Academy

- Customer training/handbooks

- Asset playbook

Optimize Your Machine Health

Reduce unplanned downtime by getting to the root cause of machine failures. Learn how KCF’s machine health optimization platform will help you achieve peak plant performance. Download the KCF Guide to learn more about optimizing your machine health.