Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.

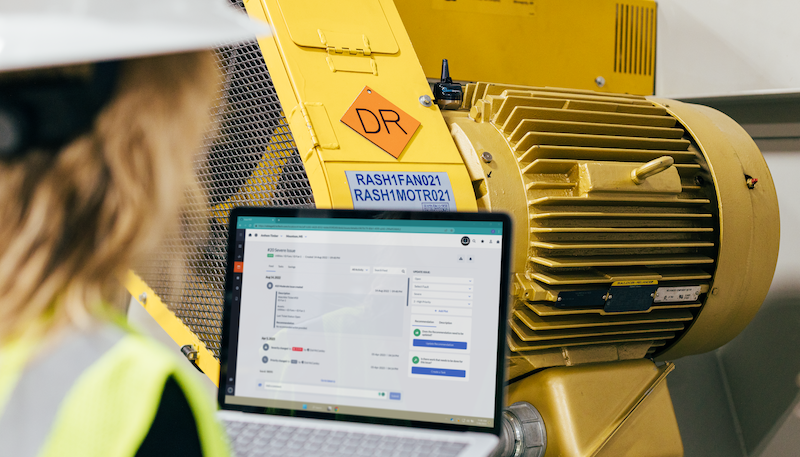

Revolutionizing Predictive Maintenance in the Automotive Industry

Discover how predictive maintenance transforms the metals industry, enhancing efficiency and reducing costs for better performance.