Reduce Unplanned Downtime with Life Sciences Production Asset Case Studies

HVAC Facilities

Maintaining clean, compliant environmental conditions is critical for producers of life sciences. Air handling equipment can be prone to failure and often inaccessible due to guarding.

- Up to $100,000/hour downtime cost

- 4-8 hours to repair or replace parts

- Low energy efficiency

- Failure degrades environmental conditions

Cooling Towers

Multiple production processes can be shut down when a cooling tower can no longer efficiently dissipate excess heat. Rising temperatures threaten product integrity, adding the price of product waste to the total cost of a failure event.

- $1,000/hour downtime cost

- $50,000 in equipment costs per failure

- Upwards of $100,000 in cost savings for one failure avoidance

Sterilization Pumps

Pumps are the backbone of aseptic life sciences manufacturing. Sterilization pumps are frequently operated under harsh conditions, causing premature failure and poor energy efficiency.

- $10,000 – $50,000/hour downtime cost

- 2-12 hours downtime, on average

- Up to 40% of consumed energy is wasted

Industry leading data acquisition in high definition while achieving a total cost of sustainment 16x less than the average competitor.

Why KCF

$4B

customer savings

75k

hours of prevented downtime

24/7

hours of monitoring

Optimize Your Life Sciences Manufacturing Performance

Life Sciences manufacturers that can avoid unplanned downtime and increase energy efficiency can realize cost savings of millions of dollars per plant per year. Knowing which maintenance actions to perform and when can help you avoid contamination and stay inspection-ready at all times.

Download the 2022 KCF Guide to learn more about optimizing your manufacturing performance today.

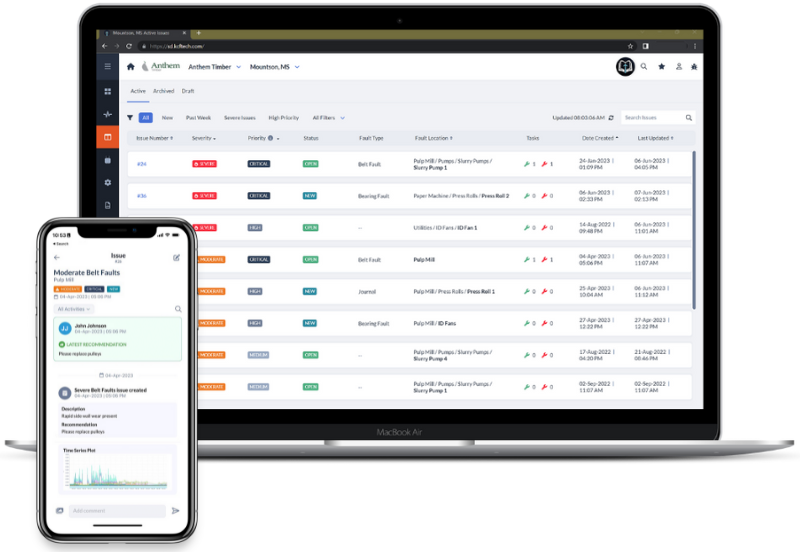

How Our Life Sciences Machine Health Optimization Platform Works

Intelligent, data-driven reliability practices set the most competitive clean manufacturers apart from the rest. SMARTdiagnostics, our comprehensive machine health platform, allows thousands of individual monitoring points on your assets to wirelessly and continuously transmit machine health data to a central cloud database.

SMARTdiagnostics’ advanced analytics capabilities get to the root cause of machine health issues. CMMS integration and personalized dashboards drive meaningful actions to keep your plant operating at its best and safest.

Enhance Your Reliability Practices

The condition of your plant is the number-one determinant of your success. Your reliability professionals and practices need to safeguard you from contamination, production stoppages, spoilage, and compliance headaches — a difficult task if they’re relying on disconnected systems, incomplete or misinterpreted data, or outdated preventive maintenance practices.

SMARTdiagnostics catches asset failures before they happen and help your team determine the environmental factors that cause them. With CMMS integration and industry-leading analytics, you can be certain that unnecessary PMs are never performed again.

Pumps and fans account for 40% of all industrial energy consumption.

Optimize for Energy Efficiency

HVAC and other air handling machinery can account for 50% or more of a life science manufacturer’s energy consumption. Improperly maintained centrifugal blower or axial fans are more prone to sudden failure but also consume more costly energy. We’ve helped manufacturers save millions by identifying the optimal running conditions and maintenance intervals for industrial fans.

On average, pumps waste between 10% and 40% of the energy they consume. Improving pump efficiency can save up to $100,000 per year per asset, translating to total savings in the millions for the average aseptic plant.

Improving pump efficiency can save up to $100,000 per year, per pump.

KCF Technologies Gives Life Sciences Manufacturers a Competitive Edge

Gain access to a team of engineers with deep life sciences production industry experience in sterile manufacturing environments, asset health monitoring, root cause analysis, and problem-solving.

Our platform was designed specifically for manufacturers facing machine health monitoring challenges that traditional solutions can’t fix. We’ll help you prevent unplanned downtime and increase productivity, safety, and revenue.