Revolutionizing Predictive Maintenance in the Corrugated Industry

March 12, 2025 | Machine Health Solutions

Introduction

The corrugated industry is the backbone of modern packaging, enabling businesses to transport goods efficiently and sustainably. However, maintaining uptime in corrugated plants is a persistent challenge, as equipment failures lead to costly downtime, lost production, and safety hazards.

KCF Technologies is transforming the industry with its predictive maintenance solutions, powered by SMARTdiagnostics®. Through real-time asset monitoring and expert-driven analytics, KCF helps corrugated manufacturers prevent failures before they occur, reducing downtime, mitigating fire risks, and optimizing operational efficiency.

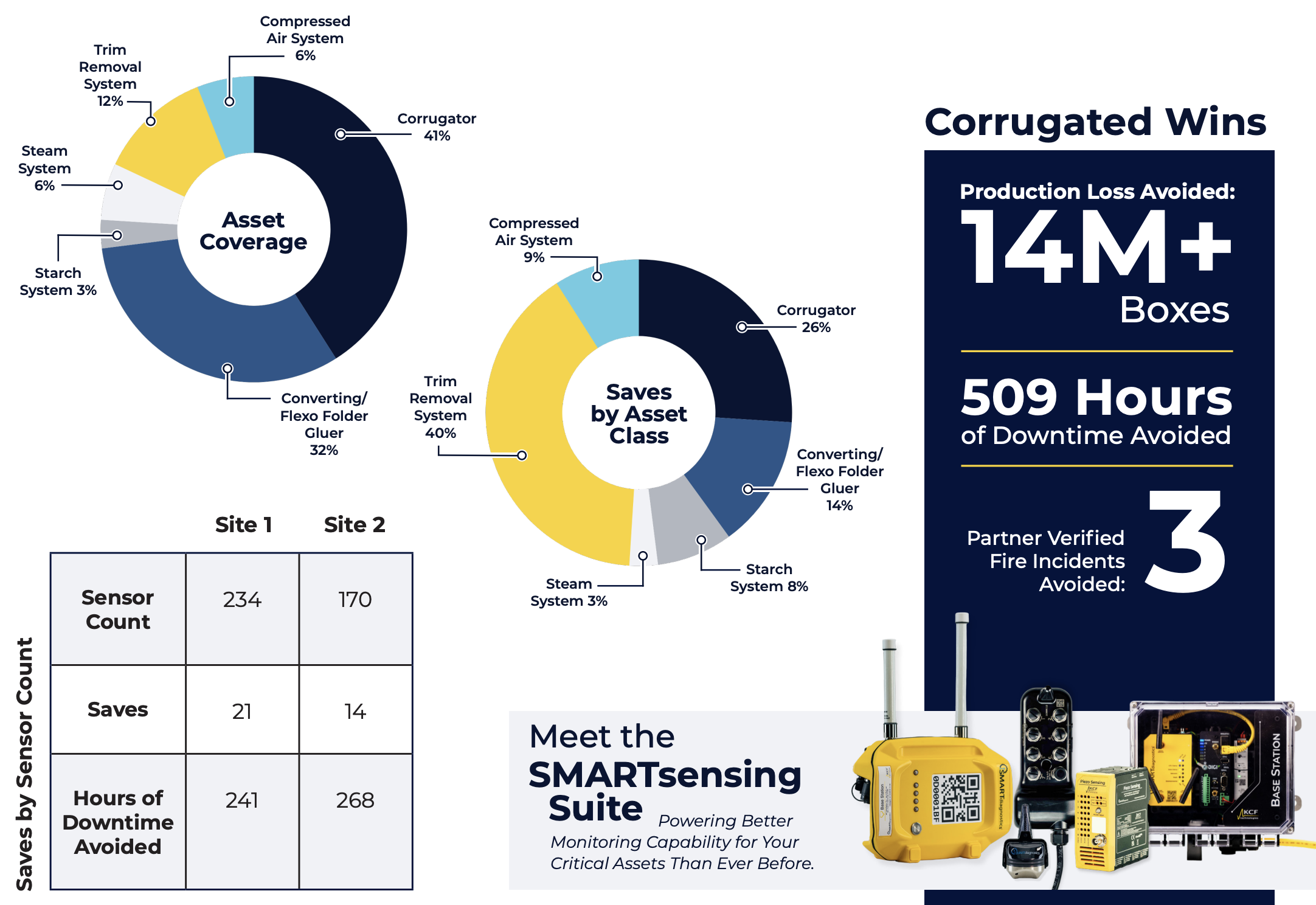

Corrugated Plant Insights

KCF’s Superior Sensor Technology

Wireless vibration sensors are a crucial enabler of predictive maintenance, but not all sensors are created equal. Many solutions on the market suffer from poor design, resulting in false positives, missed diagnoses, and erosion of trust in condition monitoring programs. KCF Technologies has set the industry standard with its patented Version 3 High-Definition sensor, engineered for unparalleled accuracy and reliability.

Sensor Overview

KCF’s High-Definition Sensor offers industry-leading data acquisition—collecting the full spectrum of data as often as once every minute. Our unique ability to take high-interval, full-spectrum data allows for a best-in-class machine learning training dataset, delivering exceptional predictive maintenance analytics.

Key Advantages of KCF’s Sensor Technology:

- Minimal Measurement Error: KCF’s sensors exhibit less than 6% error, compared to the 60-410% error range of competing sensors.

- Patented Stability Design: KCF’s vibration sensors avoid the instability issues found in many wireless solutions, ensuring accurate diagnostics.

- Proven Reliability at Scale: Unlike many predictive maintenance startups, KCF Technologies has a track record of successfully implementing scalable monitoring solutions across industries.

Corrugated Case Studies: Real-World Successes

Trim Blower Fan Failure Prevention

KCF’s SMARTdiagnostics software detected excessive vibration in a trim blower fan due to an imbalance. Upon inspection, cracks were discovered in the fan’s frame and welds. The customer proactively shut down the fan, avoiding a catastrophic failure that could have resulted in six months of operating at a reduced capacity and a production loss of 277,000 boxes per week.

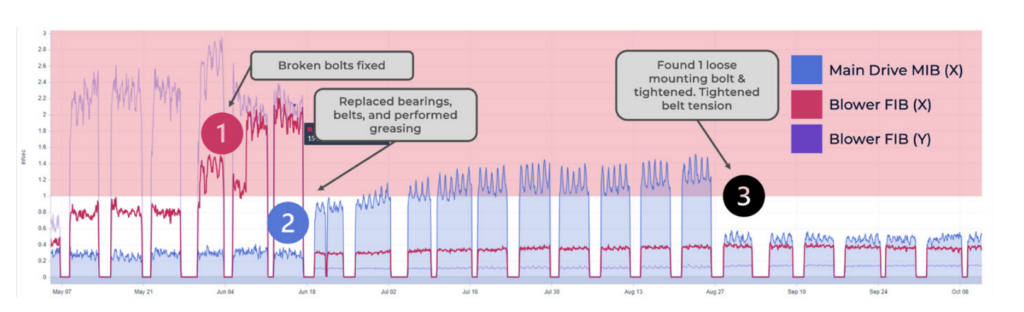

Fire Hazard Avoidance in Trim Removal System

A temperature spike in a trim removal system’s main drive motor signaled a potential failure. Upon investigation, excessive scrap buildup was blocking airflow, creating a fire hazard. Cleaning the debris restored the system to optimal operation, preventing a dangerous event and saving the company $20,000 in fire-related costs.

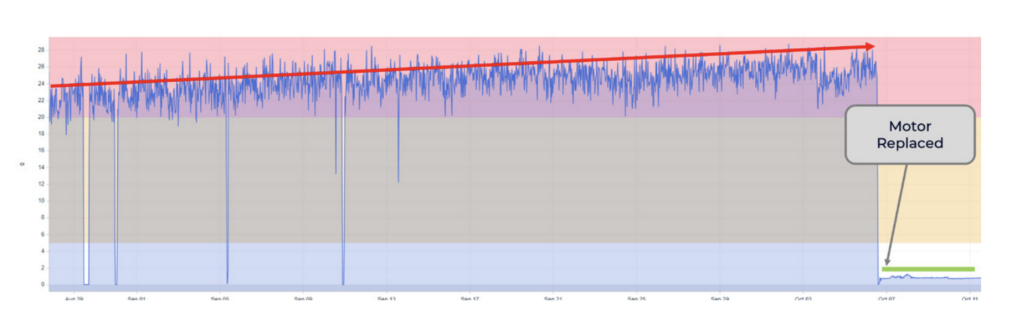

Proactive Bearing Fault Detection in a Starch System

Vibration analysis identified a bearing fault in a starch feed pump motor. Without a spare motor on hand, the customer had to order a replacement. Because KCF’s predictive analytics provided early detection, the new motor arrived and was installed before failure occurred, avoiding 47 hours of downtime.

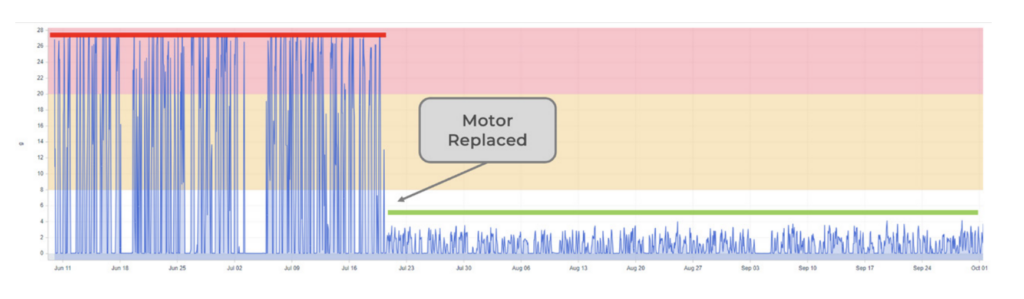

Corrugator System Optimization

Immediately after installing KCF sensors, an analyst detected high vibration in a single facer motor due to bearing wear. The bearings were dry and rough, necessitating a motor replacement. Thanks to rapid data collection and analysis, the customer acted swiftly, reducing vibration levels by a factor of nine and avoiding unnecessary downtime.

Why Choose KCF Technologies?

KCF Technologies goes beyond traditional maintenance by combining advanced sensor technology, industry expertise, and real-time data analysis.

Our Predictive Maintenance Approach Delivers:

• Faster issue detection to prevent failures before they occur

• Significant cost savings from downtime prevention and asset longevity

• Enhanced safety by mitigating fire hazards and operational risks

• Industry-leading sensor accuracy ensuring data integrity for reliable decision-making

• Increased production efficiency by maintaining optimal machine performance

Conclusion

In the highly competitive corrugated industry, operational reliability is essential. KCF Technologies empowers manufacturers with the tools they need to achieve zero unplanned downtime, zero waste, and zero injuries. By leveraging SMARTdiagnostics® and expert guidance, companies can maximize production, safeguard their workforce, and stay ahead of costly failures.

Learn how KCF’s machine health optimization platform will help you achieve peak plant performance at kcftech.com