Asset Saves

Explore how smart strategies can turn simple actions into significant rewards.

Homogenizer Motor

$15,000

Capital Expenditure

6 hours

Downtime Avoided

The Problem:

The Homogenizer C motor DE bearing shows severe looseness, vibration, and fluting-related faults.

How We Solved It:

The motor was adjusted, bearings and wiring replaced, and ceramic bearings recommended to address persistent vibration and electrical issues.

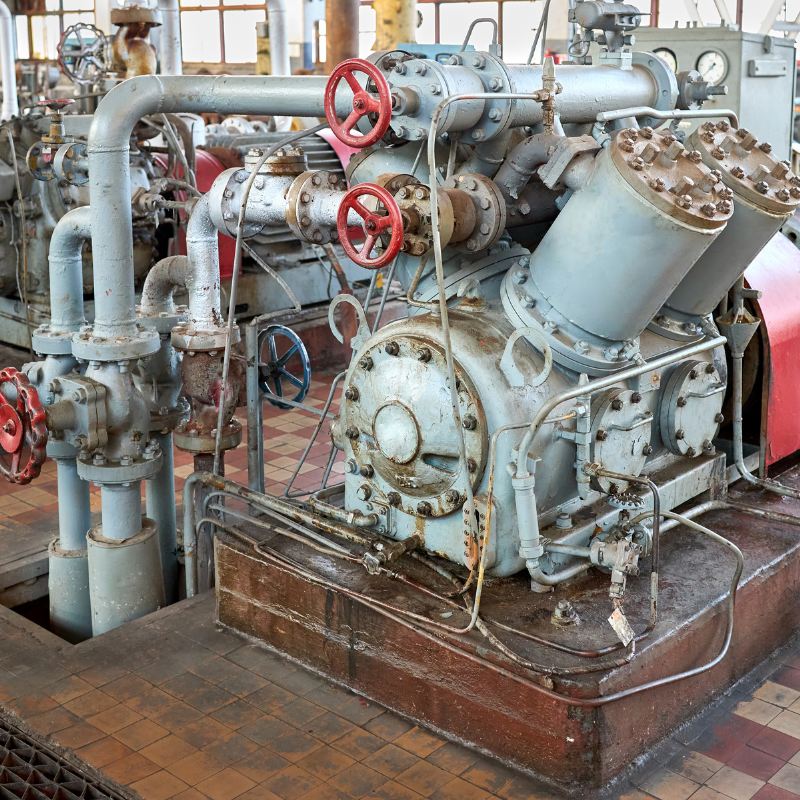

Ammonia Compressor

$600,000

Customer Savings

4 hours

Downtime Avoided

The Problem:

A compressor showed doubled vibration levels due to structural or rotating looseness.

How We Solved It:

The motor replacement resolved elevated running speed vibration, significantly reducing levels, avoiding downtime, and closing the issue.

Digester Outlet Device

$55,000

Customer Savings

5 hours

Downtime Avoided

The Problem:

The motor exhibited suspected outlet and bearing driver faults with amplitude growth and gear impacts at 288 RPM.

How We Solved It:

Following expert recommendations, the motor and outlet bearings were replaced during scheduled downtime.

Stamping Hydraulic Pump

$23,701

Customer Savings

1 hour

Downtime Avoided

The Problem:

A SENTRY Analyst detected increased acceleration on a hydraulic pump, prompting a maintenance review that revealed cavitation as the root cause.

How We Solved It:

The on-site maintenance team resolved the issue by identifying the filter as the problem, replacing it, and restoring the pump to a healthy state.

Screw Compressors

$240,000

Customer Savings

1,000 hours

Downtime Avoided

The Problem:

Thrust bearing wear in screw compressors can lead to operational failure by halting the flow of high-pressure gaseous fluids.

How We Solved It:

The team recommended replacing the thrust bearing to prevent screw damage and avoid costly downtime and repairs.

Trim Blower Fan

$16,572

Repair & Maintenance

29 hours

Downtime Avoided

The Problem:

The Trim Blower Fan motor experienced increased low-frequency vibration due to imbalance, confirmed upon inspection and addressed by cleaning and balancing the fan during scheduled downtime.

How We Solved It:

The issue was resolved by shutting down the fan for offsite repairs, avoiding catastrophic failure and minimizing downtime to two weeks instead of six months.