Additional Operating Data Uses Unlocked by MCSA/ESA in KCF’s Machine Health Platform:

MCSA & ESA

Next-level motor diagnostics powered by MCSA and ESA

The addition of Motor Current Signature Analysis (MCSA) and Electrical Signature Analysis (ESA) to KCF’s comprehensive machine health platform combines MCSA’s and ESA’s robust motor-electrical diagnostic capabilities with the high-fidelity continuous monitoring, ease of installation, and focus on root cause eradication that are central to KCF’s solutions. Pairing this technology with vibration monitoring results in a comprehensive asset health solution crafted for your most critical electric motors.

- Stator shorts

- Rotor bar failures

- Power consumption

- Power factor

- Duty cycle

- Inrush duration + magnitude

- Phase imbalance

When should you use MCSA/ESA?

1. Costs of downtime are high

When failure costs a significant sum due to lost production.

When failure costs a significant sum due to lost production.

2. Failure prevention is essential

When motor replacement cost is significant, or failure results in collateral damage such as product needing to be discarded, or adjacent equipment being damaged.

3. Regulatory & fines risk reduction

When catastrophic failure results in fines levied against the customer.

4. Energy consumption

When energy costs matter and a customer needs to reduce its carbon footprint.

Our MCSA/ESA solution unlocks:

01

Provides continuous online monitoring with 24/7 access to critical data. Effectively covering all blind spots that exist between readings in periodic route-based monitoring.

02

Allows motor behavior during start up to be trended over time, enabling early detection of damaging conditions and motor issues.

03

Route-based analysts or maintenance staff members no longer need to enter dangerous environments to take readings.

04

The inclusion of potential transformers facilitates power supply monitoring. This enables the identification of chronic power supply issues, eliminating the cause of motor faults and suboptimal performance.

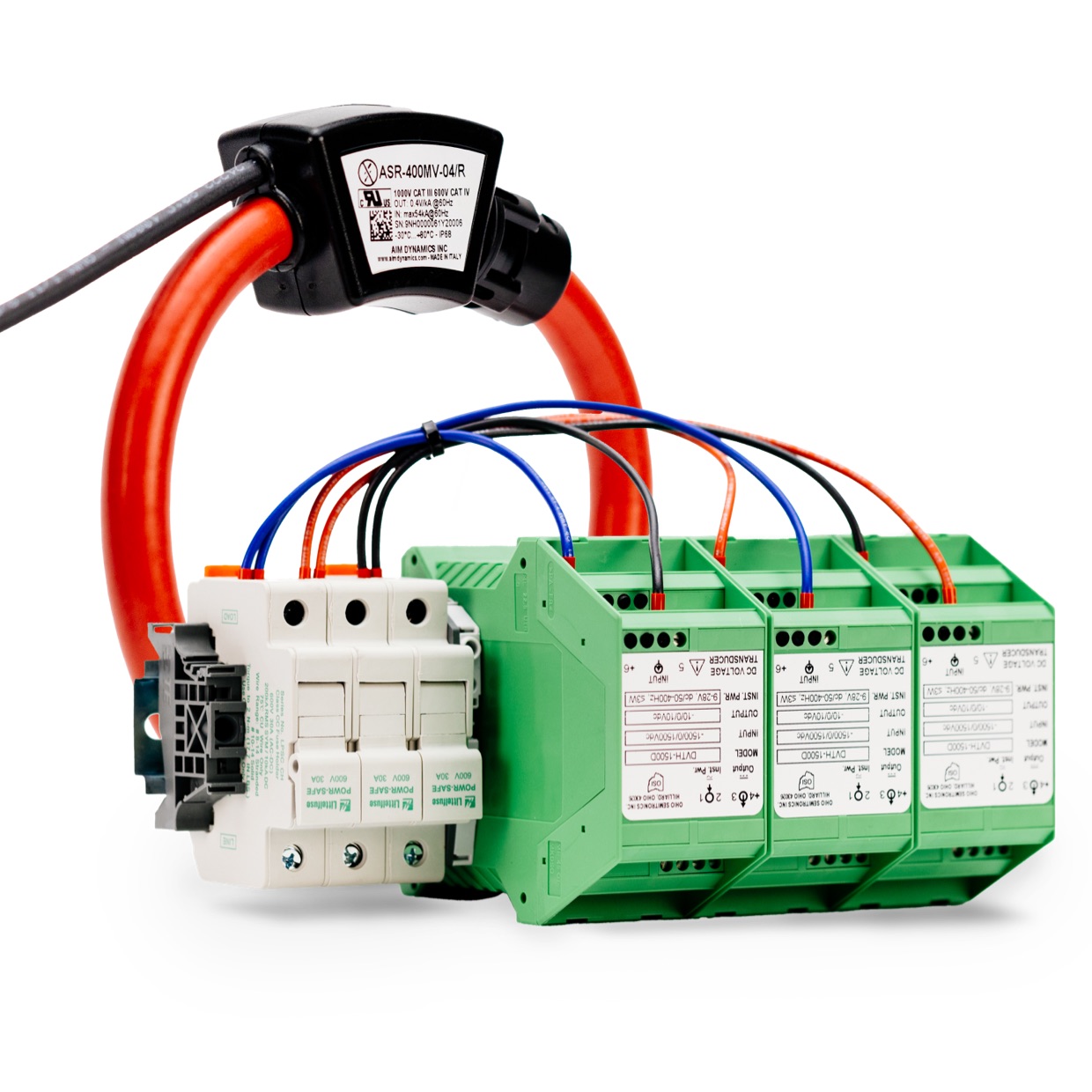

Motor Current Signature Analysis (MCSA) Hardware

The IoT HUB

Transmits full-spectrum data to KCF’s machine health platform, SMARTdiagnostics.

Analog Adapters

Connects each of the transducer types to the IoT HUB.

Current Transducers (CTs)

Identifies motor faults.

Motor Current Triggering*

Enables synchronized sampling on motor startup, enabling the detection of inrush current.

Tachometer*

Provides precise reading of motor (rotor) turning speed—important for MCSA/ESA Analytics Model.

Voltage Transducers (VTs)*

Enables electrical signature analysis (ESA) to identify power supply issues.

*Optional Hardware

Check out the rest of our SMARTsensing Suite

Request a demo

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven machine health platform can optimize your operations.