Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.

SMARTsensing Suite

Unlock the power of predictive maintenance with with the SMARTsensing hardware suite. Our rugged, scalable solutions provide the insights you need to detect failures before they happen.

SMARTsensing Suite

Wireless Vibration Sensor

KCF’s Wireless High-Definition Vibration Sensor sets the industry standard for real-time, high-fidelity predictive maintenance platform. Engineered for rugged environments, this battery-powered, wireless sensor captures full-spectrum vibration data up to every minute, for early detection of potential failures.

SMARTsensing Suite

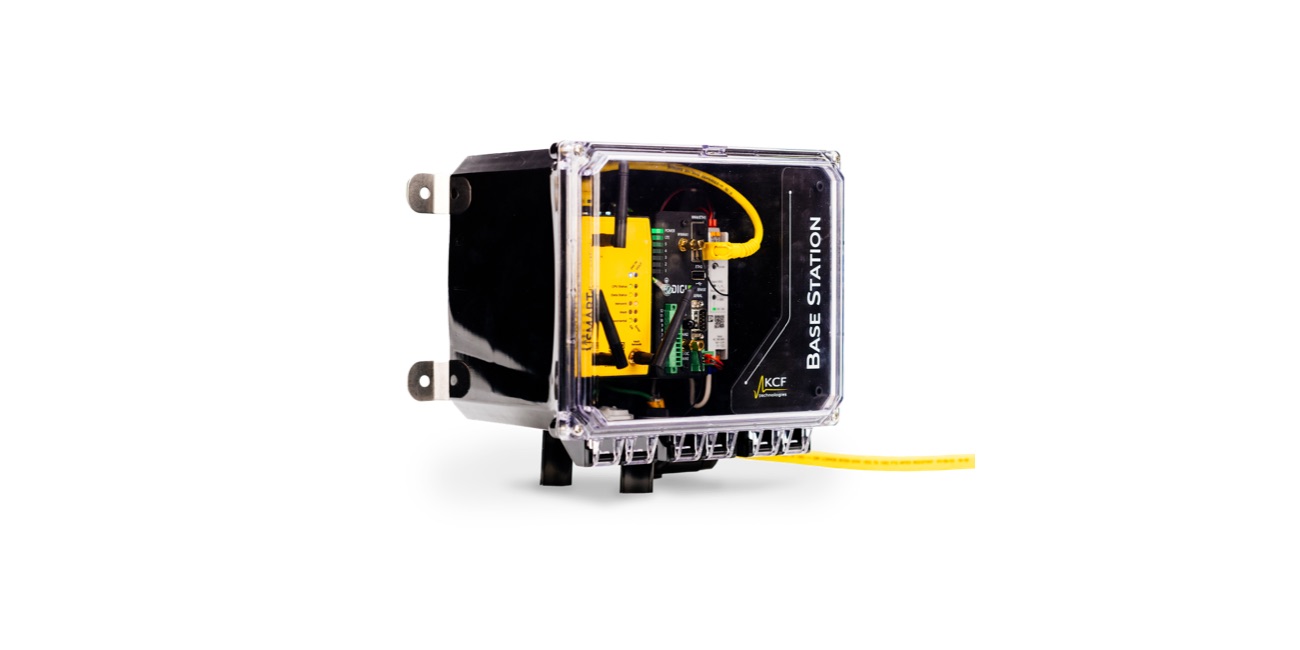

Base Station Gateway

The Base Station Gateway is the central hub of KCF’s SMARTdiagnostics predictive maintenance platform, seamlessly connecting sensors across your facility. This rugged, industrial-grade gateway enables real-time machine health monitoring by securely transmitting sensor data.

SMARTsensing Suite

IoT HUB

The IoT HUB is designed to handle complex monitoring needs where traditional wireless solutions may not suffice. With 7 input channels, the IoT HUB captures synchronous, high-fidelity data from multiple sensor types providing a complete view of asset health in a single predictive maintenance platform.

SMARTsensing Suite

Haz Loc Base Station

Engineered for hazardous environments, the Haz Loc Base Station uses KCF’s patented Dart Wireless protocol to securely transmit full-spectrum sensor data every minute—without interfering with existing plant Wi-Fi. Its mesh network ensures long-range communication, extended battery life, and maximum reliability.

SMARTsensing Suite

Piezo Sensing

Extend your monitoring capabilities to assets with large, slow rotating equipment and high speed applications using KCF’s Piezo Sensing technology. Designed to detect early-stage faults that traditional vibration sensors may miss, Piezo Sensing provides ultra-sensitive, high-resolution data for critical equipment health insights.

SMARTsensing Suite

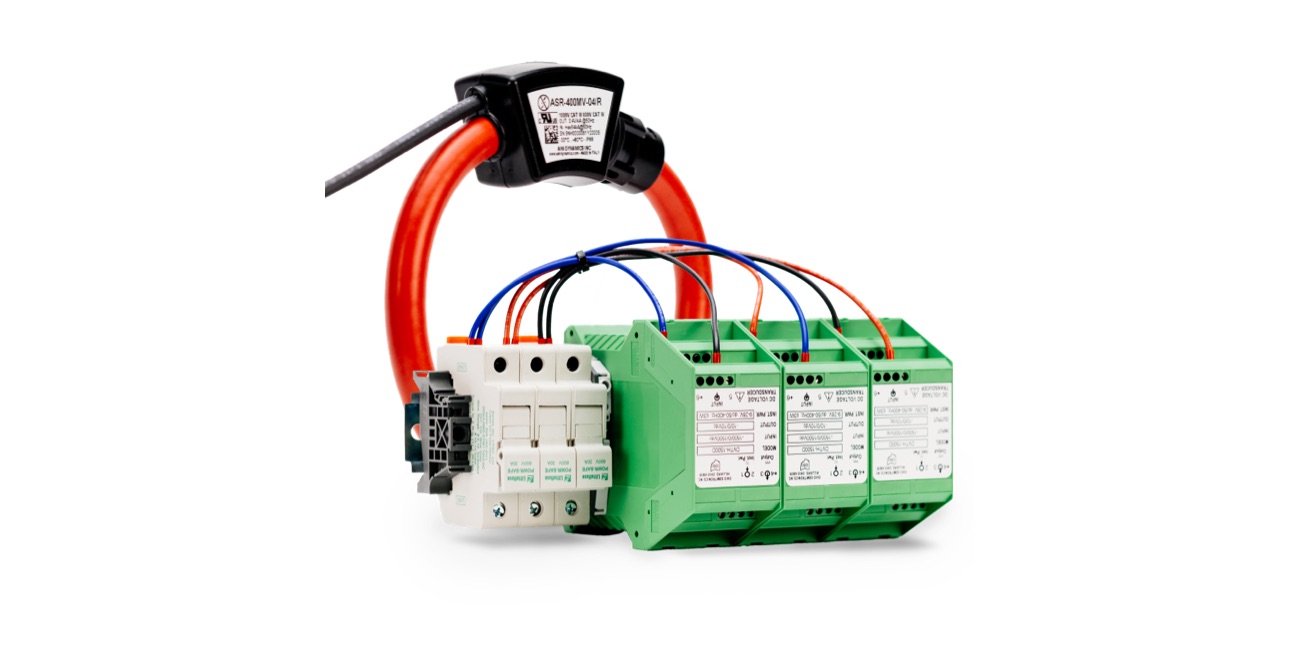

MCSA and ESA

The addition of MCSA and ESA (Motor Current Signature Analysis and Electronic Signature Analysis) to KCF’s comprehensive predictive maintenance platform combines robust motor-electrical diagnostic capabilities with the high-fidelity continuous monitoring, ease of installation, and focus on root cause eradication that are central to KCF’s solutions.