Overfire Air Fan

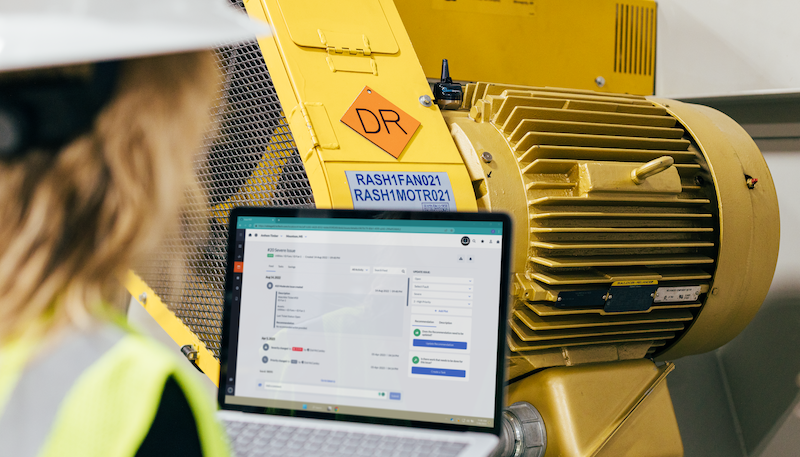

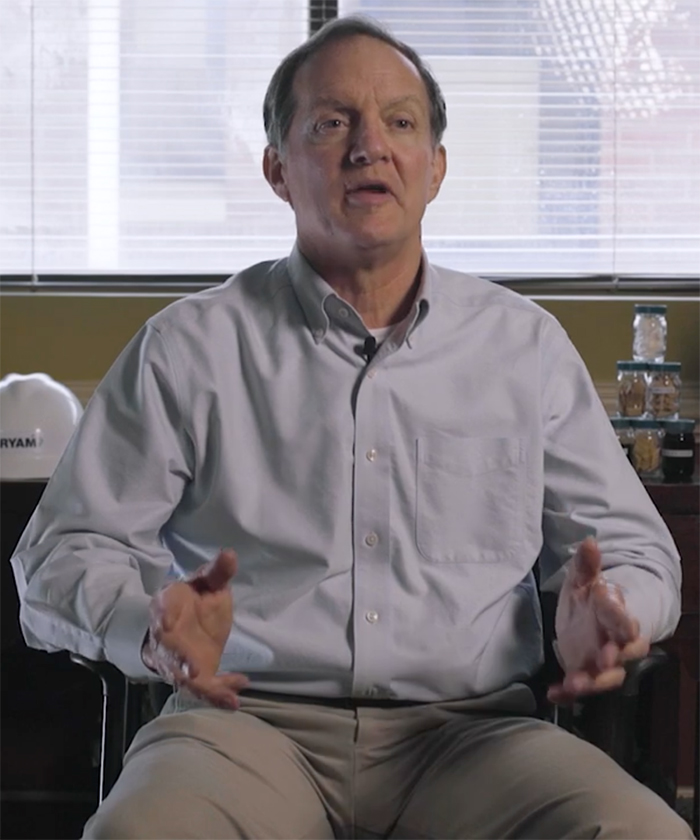

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

See how KCF helps you increase yield while maintaining sustainability

One thing all lumber mill assets have in common is their criticality: any downtime on a single machine can have severe impacts on overall production. Specialized machinery requires advanced maintenance skillsets and presents significant safety issues if something goes wrong.

Machinery used in the production of corrugated paper products can be difficult to monitor, and the industry has been deeply impacted by supply chain issues causing long lead times for critical replacement parts. Time- and route-based monitoring aren’t enough to maintain optimal machine performance and ensure operational safety.

Time-based maintenance protocols don’t accurately capture damage inflicted on OSB production assets due to their short run cycles and intermittent operations. Even minor deviations in machine performance can result in major impacts on product quality.

Mechanical faults that slip detection with traditional reliability practices can result in high levels of rejected board material. Fans and conveyance assets are typically hard to safely monitor but are critical to ensure continuous operations.

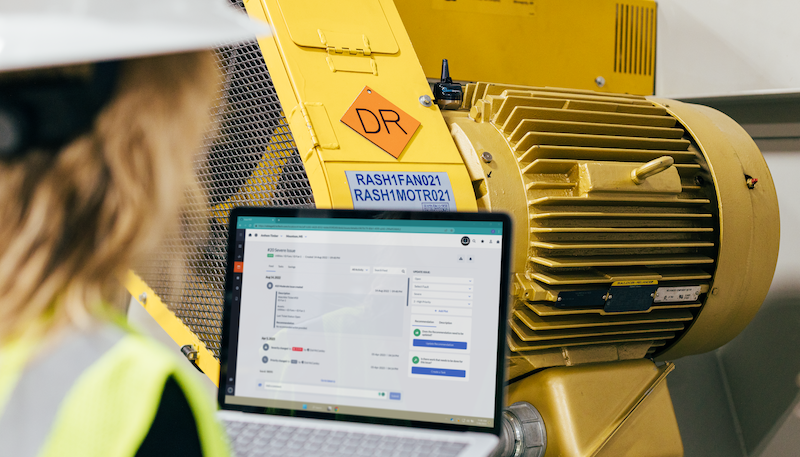

KCF Technologies’ SMARTdiagnostics system aids the pulp and paper industry by enhancing equipment monitoring and maintenance. It helps detect early signs of equipment issues, allowing for proactive maintenance and minimizing disruptions. This system focuses on critical processes like bleaching and thick stock pumping to ensure smooth and efficient operations.

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

Discover how KCF Technologies is revolutionizing predictive maintenance for the corrugated industry to enhance efficiency and reduce costs.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.