Introduction

Paint fans located in paint booths are the most common asset typically monitored in an Automotive paint shop.

Paint booths are sealed environments with regulated pressure that use robots to apply paint to vehicles. Within a paint booth, they are four types of fan system you will encounter, each playing an important role in the painting process.

Many Automotive facilities have relied on route-based monitoring or time-based maintenance to monitor the health of their equipment. However, with the rise of predictive maintenance, there has been a shift towards real-time, condition-based monitoring.

Exhaust Fans

Exhaust fans pull air out of the paint booth.

Green dots show sensor locations.

Green dots show sensor locations.

Supply Fans

Supply fans push air into the booth to replace the air removed by the exhaust fans.

Recirculation Fans

Maintains air circulation within the booth.

Regenerative Thermal Oxidizers (RTO)

Plays an important role in destroying hazardous air pollutants and emissions created during the painting process. They have strict environmental regulations and can be prone to EPA fines if not followed.

Many Automotive facilities have relied on routebased monitoring or time-based maintenance to monitor the health of their equipment. However, with the rise of predictive maintenance, there has been a shift towards real-time, condition-based monitoring.

Case Study

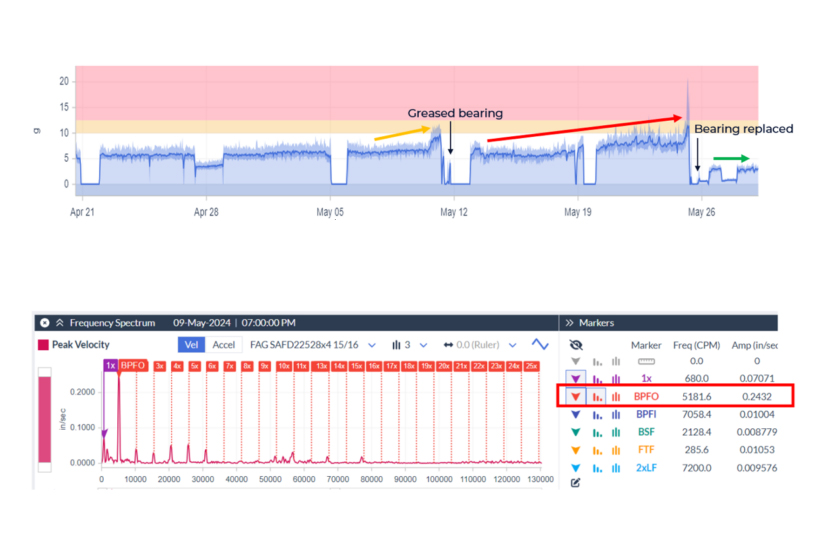

In the given example, there is an increase in peak acceleration on an exhaust fan inboard bearing. The first increase led to a warning notification that triggered maintenance into greasing the bearing. While this temporarily remediated the symptoms, an underlying issue still existed. Following greasing, the trend increased to even higher levels than before within two weeks. Using SMARTdiagnostics built-in bearing database, frequencies from this specific bearing were observed. The spectrum showed harmonics of the BPFO, which indicates wear on the outer race of the bearing.

With this information, it was determined that the bearing had reached the end-of-life and should be replaced.

Getting Started with Paint Fans Monitoring

Hardware Needed

- Four High Definition Vibration Sensors

- Base Station

- Optional: IoT HUB to monitor current and pressure in addition to vibration and temperature

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.