Introduction

KCF Technologies’ Machine Health Platform offers comprehensive solutions that cater to these complexities, particularly with its advanced Piezo Sensing module designed for low-speed, high-temperature environments, such as dryer cans .

Dryer cans, which comprise the longest and most critical section of the paper machine, are particularly difficult to monitor due to their slow operational speeds and high temperatures. With around 40 to 70 dryer cylinders in a typical machine, KCF’s Piezo Sensing Solution stands out as the premier choice for effectively monitoring these vital bearings. By leveraging advanced enveloping techniques and delivering handheld-analyzer quality data, this solution detects bearing anomalies months in advance in dryer cans, ensuring optimal performance and equipment longevity in the paper-making process.

Introducing Piezo Sensing

Detecting early stage bearing wear can be challenging without the right technology. KCF Technologies’ Piezo Sensing utilizes advanced high-frequency enveloping to isolate and highlight subtle impacts, achieving superior bearing fault detection. With the capability to record 96,000 samples per second and monitor equipment as slow as 2 RPM, this solution excels in diagnosing issues that other methods may miss. In addition, its ruggedized build allows it to withstand temperatures as low as -4F and as high as 149F.

The enveloping technology also targets low-frequency faults, providing a significant advantage in equipment diagnostics. This approach facilitates early detection of bearing faults by pinpointing impact sources, making Piezo Sensing an essential tool for monitoring critical machinery, as demonstrated in a case study of rotating looseness in a dryer drum.

Raw Data vs Enveloped Data

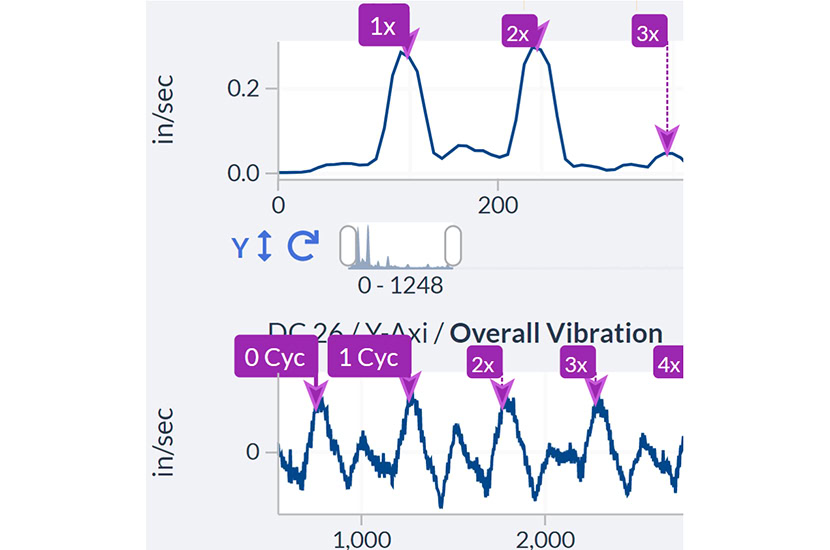

Here you can see the raw wave form on a slow-turning Dryer Can bearing that shows clear impacting at intervals of a few seconds. Because the impacts are generated by the scraping of metal on metal, high frequency vibrations spaced far apart are generated, however the raw spectrum doesn’t do an adequate job of distinguishing that frequency.

To uncover low frequency issues, we need to be able to resolve the low frequency spacing of the impacts. Without Piezo Sensing, the raw data within the FFT shows no evidence of consistent spacing. Enveloping is a signal processing technique that extracts the overall amplitude of high-frequency vibrations, smoothing out individual peaks so that each cluster of vibrations appears as a single, distinct pulse. This approach enhances the detection of recurring patterns, such as early-stage bearing faults, by highlighting characteristic frequency signatures.

In this example

A traditional FFT (in blue) misses the spacing of the impacts seen in the waveform. With enveloped data, shown in yellow a clear train of harmonics at the frequency of the impacts can be seen. Note, these impacts are at only 0.6 Hz or 35RPM. Traditional sampling cannot reveal these impacts or resolve peaks at a such low frequencies, while enveloping can.

Raw Data

Enveloped Data

In another example

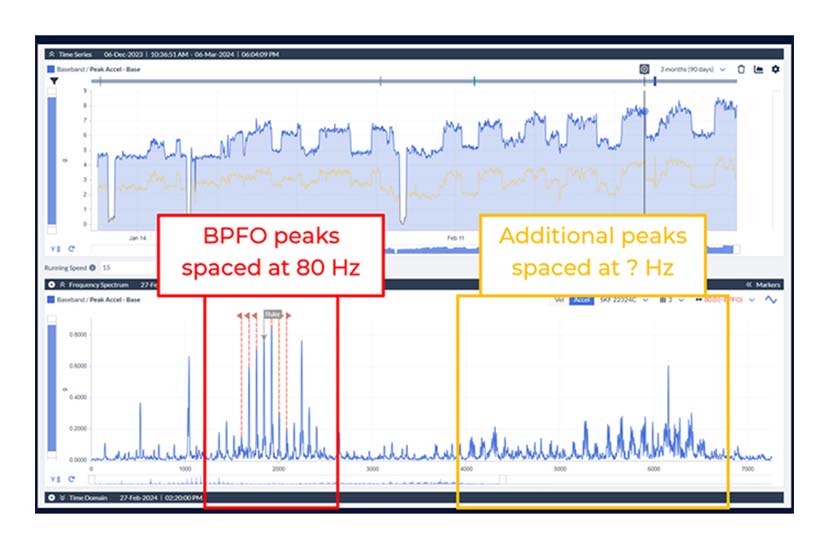

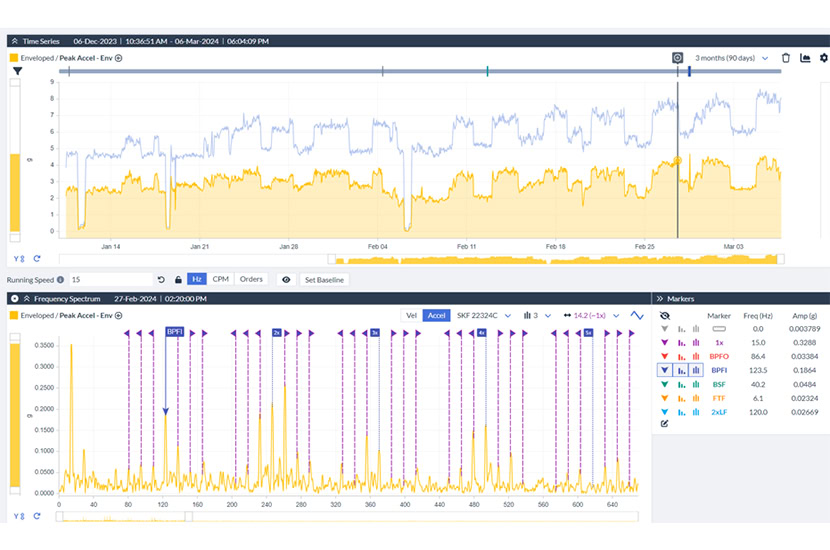

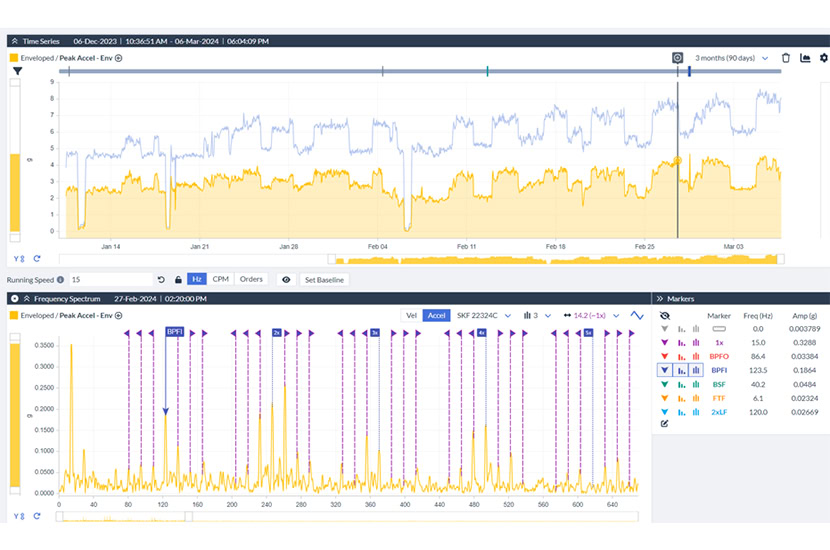

The image shows a concerning trend on a high-criticality bearing. There are obvious peaks in the raw FFT spaced at the BPFO (80 Hz). In addition, there appear to be peaks higher in the spectrum spaced at an unknown higher frequency.

When enveloped

The FFT displays harmonics of the BPFI (123 Hz) with side bands of the run speed (15 Hz). Using enveloping, both BPFO and BPFI faults can be detected and tracked over time.

BPFO peaks spaced at 80 Hz

Dryer Cans Case Studies

Dryer cans are pressurized steam vessels that make direct contact with fiber for drying purposes. When steam exchanges heat, it becomes condensate which then must be evacuated with a syphon.

Some common failure modes seen on dryer cans are:

- Bearing lubrication

- Bearing failures

- Steam Leaks (washing out bearings)

- Condensate Locking/Evacuation Issues

- Looseness

Fault Type

Condensate Evacuation Fault

Time Wave Form

- Typically appears like a misalignment

- Will often see ‘M’ and ‘W’ shapes

Frequency Spectrum

- 2x will likely be the dominant frequency with 1x sometimes being elevated

Recommended Action

- Use an Infrared gun to check temperature (30-50F lower than nearby cans) -does this lower temperature indicate a problem? What is the significance of this lower temperature

- Check if discharge valves are open or locked

Root Cause

- A plugged syphon/discharge valve

- Discharge valve being in the closed position

Fault Type

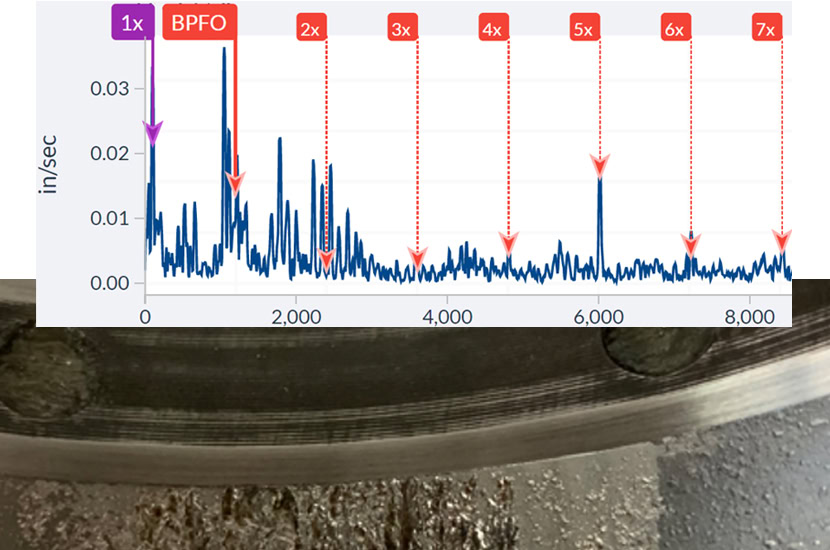

Bearing Wear

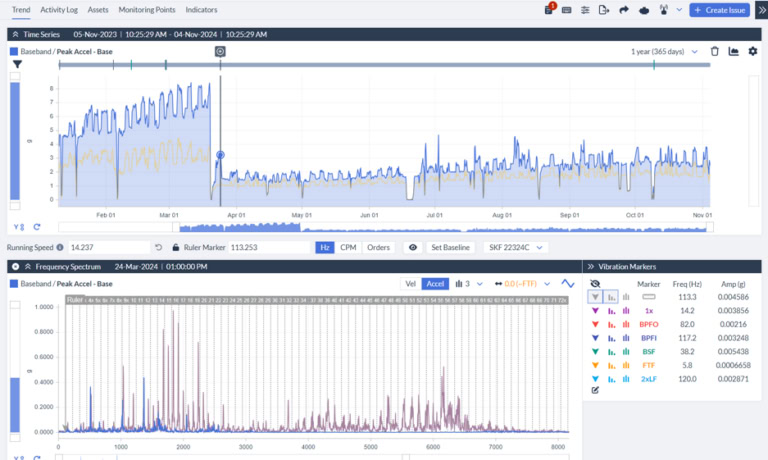

Frequency Spectrum

- Harmonics of the bearing frequency and even low amplitudes can still indicated bearing wear is present

- With bearing wear, sides at the spacing of the run speed can be seen

Recommended Action

- Plan for replacement on next scheduled outage

Root Cause

- A combination of: Steam flushing out lubrication; Pulp/water infiltration into bearing; General wear over time

Fault Type

Bearing Damage

Run speed

78RPM

78RPM

Issue

Condensate can fail to evacuate from dryer cans resulting in less drying capacity and higher wear on the bearings

Monitoring Technique

Low pass filter with alarms for temperature and vibration.

Result

Early detection of a developing fault, which ensured work order could be executed quickly with minimal system instability and full drying capacity.

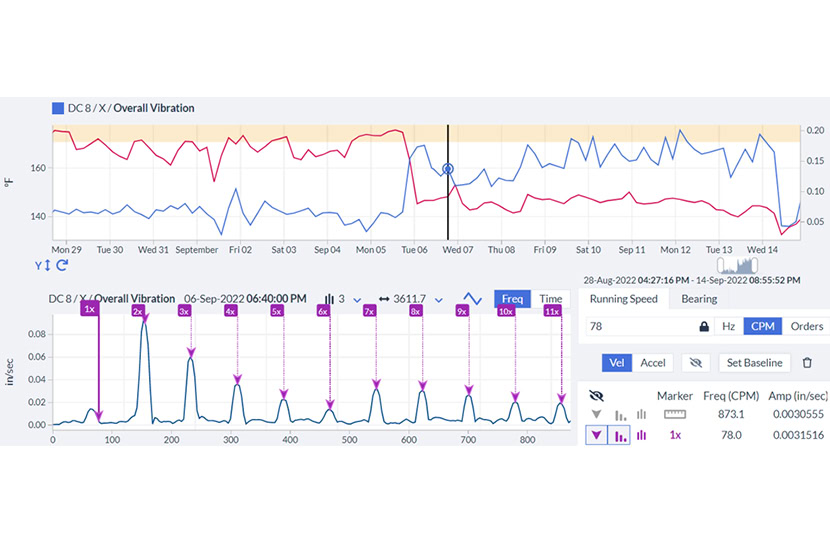

Example: Flooded Dryer Can

Vibration (Blue) Temperature (Red)

Fault Type

Fluting

In another case study, the image below shows a concerning trend on a high-criticality bearing. There are obvious peaks in the raw FFT spaced at the BPFO (80 Hz). In addition, there appear to be peaks higher in the spectrum spaced at an unknown higher frequency.

When enveloped, the FFT displays harmonics of the BPFI (123 Hz) with side bands of the run speed (15 Hz). Using enveloping, both BPFO and BPFI faults can be detected and tracked over time.

The cause of the faults was found to be due to Electrical Discharge Machining from current leaking across the motor/gearbox coupling. Following this discovery, the customer installed an electrical discharge kit to isolate the two from each other, causing a drop in vibration back to healthy levels.

Getting Started with Dryer Can Monitoring

Hardware Needed

- Piezo Sensing Acquisition Unit

- DIN Mount Enclosure with Power supply

- High Temp Cabling

- Piezoelectric Accelerometers

- Base Station

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.