Download the predictive maintenance playbook.

Enter your email to download the Predictive Maintenance Playbook and transform your maintenance strategy starting today.

KCF Technologies provides SMARTdiagnostics® wireless vibration and machine-health analytics across Precision’s fleet, transforming high-fidelity sensor data into clean, contextualized insights. Prescient fuses those insights with real-time operational data such as EDR, RPM, torque, load, and maintenance history, creating a digital twin that reflects the true operating state of each rig. Precision’s field crews and Alpha Remote Operations Center act on those insights daily, which enabled the organization to scale from pilot to full-fleet deployment in just eighteen months.

“The most important thing that we can provide to Precision is clean, contextualized data that enables them to go solve very real problems.“

Jeremy Frank

CEO

KCF Technologies

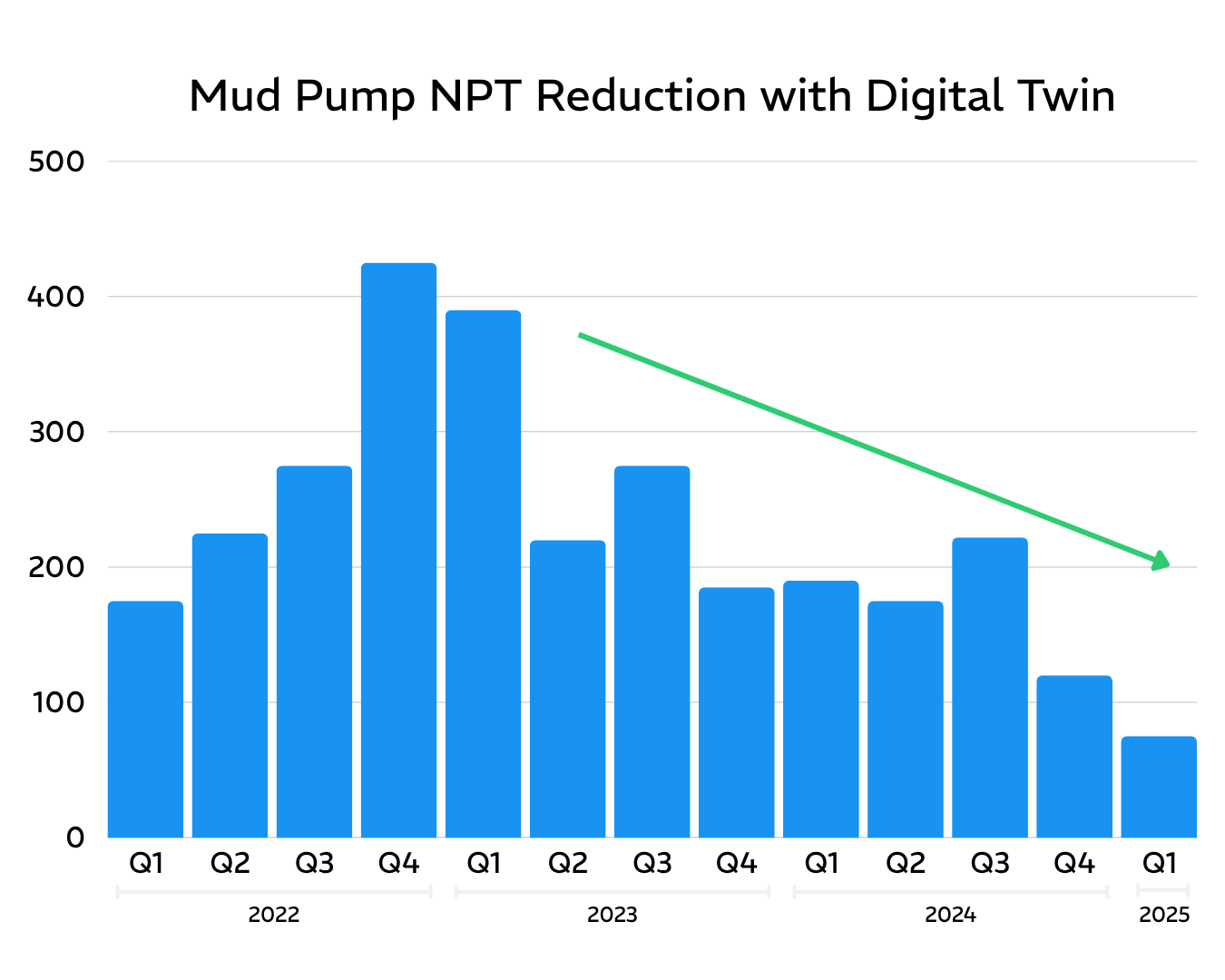

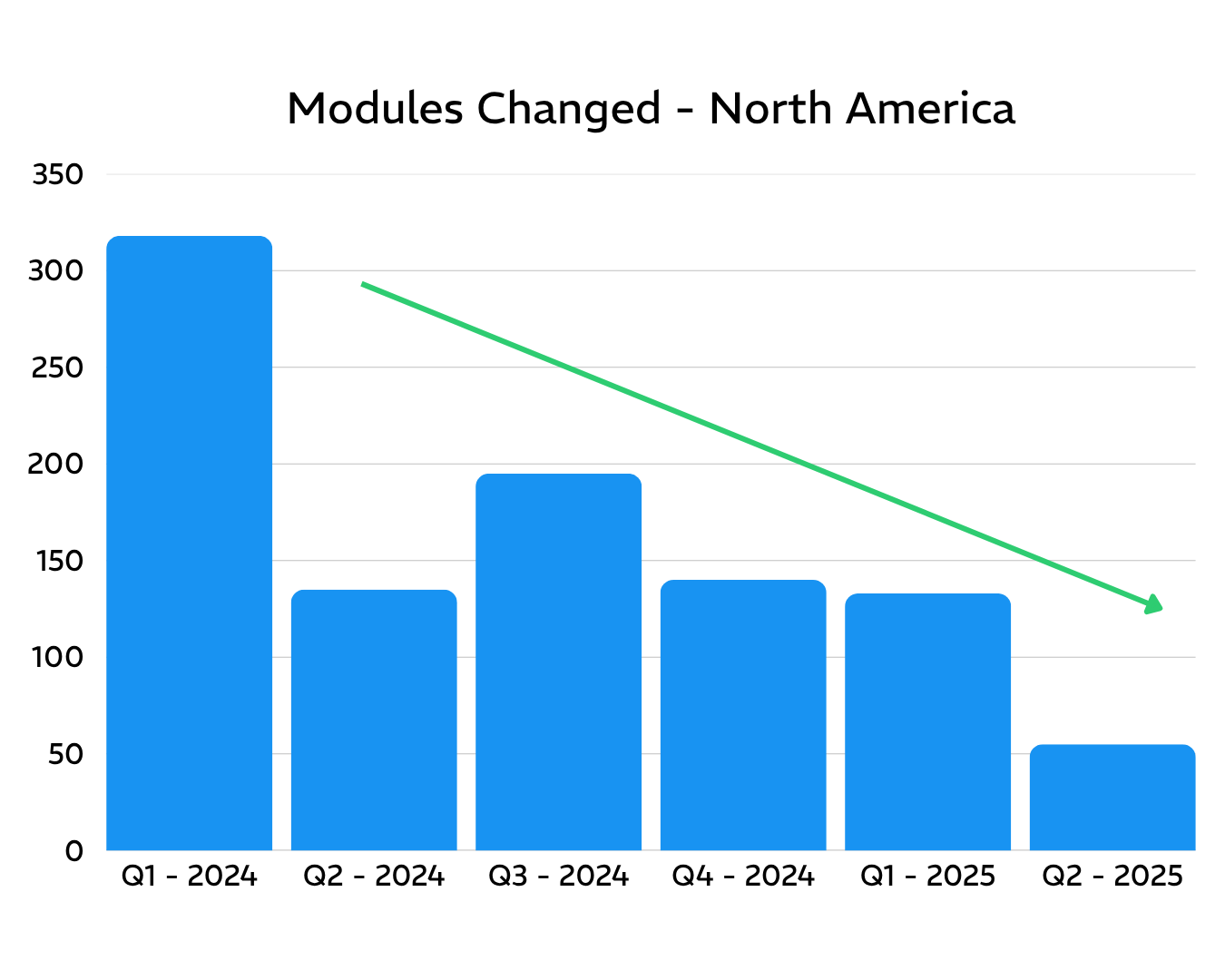

The oil field has never lacked data. The challenge is knowing what matters. By combining KCF’s machine-health signals with real-time operating context from Prescient, Precision can now distinguish normal load-driven vibration from true faults, particularly on variable-load assets like mud pumps and top drives. This clarity empowers teams to prioritize confidently, schedule maintenance proactively, and prevent costly downtime.

“Before, what we used to do was run equipment until it failed. Now we can shorten the learning curve and take more efficient action before we see impactful failures,” said Russell Whitney, Global Innovation Manager at Precision Drilling.

A single, trusted source of machine-health data now informs decisions across the organization. Best practices from Precision’s most experienced technicians are codified into system rules that help new team members ramp quickly and take confident action. Because variable-load compensation reduces false positives, teams trust the alerts they receive, turning insights into consistent, proactive interventions that keep rigs operating at peak performance.

The measurable outcomes have been remarkable. Precision achieved a 90% reduction in downtime-related credits and a 28% improvement in on-bottom performance compared to rigs not using the solution. KCF’s AI continuously processes hundreds of gigabytes of signal data in real time, while Prescient’s digital twin provides operational context that allows Precision teams to act faster, extend asset life, and reduce cost per operating hour.

“We would not be where we are today if it weren’t for leaning on the expertise of these partners, really building on the shoulders of giants. And we’re very fortunate to have KCF and Prescient as our partners.“

Russell Whitney

Global Innovation Manager

Precision Drilling

The collaboration continues to evolve as we expand coverage across more asset classes, deepen real-time analytics, and refine the digital twin with even greater operational context. The shared goal remains clear: to keep rigs reliable, available, and productive while improving safety and reducing cost.

When clean, contextualized data meets real-time insight and a team ready to act, predictive maintenance becomes a catalyst for growth. Together with Precision Drilling and Prescient, KCF Technologies is proving that connected, data-driven performance is the future of drilling.

Enter your email to download the Predictive Maintenance Playbook and transform your maintenance strategy starting today.