Russell Whitney

Global Innovation Manager

Precision Drilling

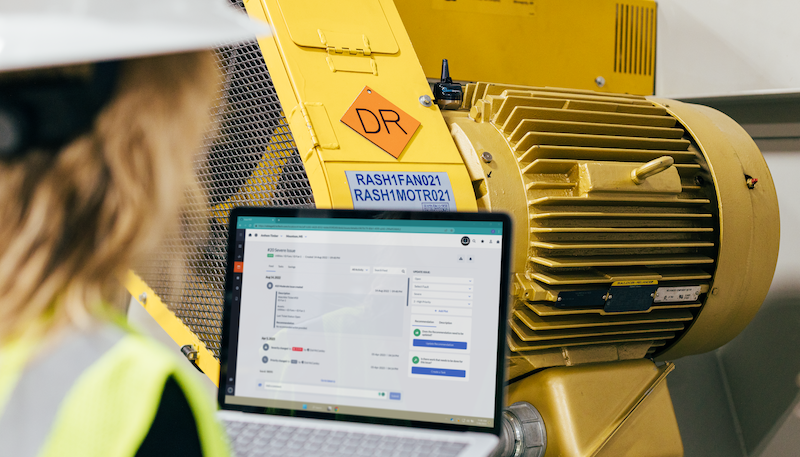

Overfire Air Fan

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

See how KCF helps you maximize revenue and reduce downtime

Discover the savings potential when you optimize your performance and efficiency within key hydraulic fracturing system configurations. Asset blind spots are revealed and new approaches are outlined in this guide.

Get solutions to common issues with drilling equipment. Compare the cost of asset failures with potential savings when our machine health optimization platform is employed to address issues before they happen.

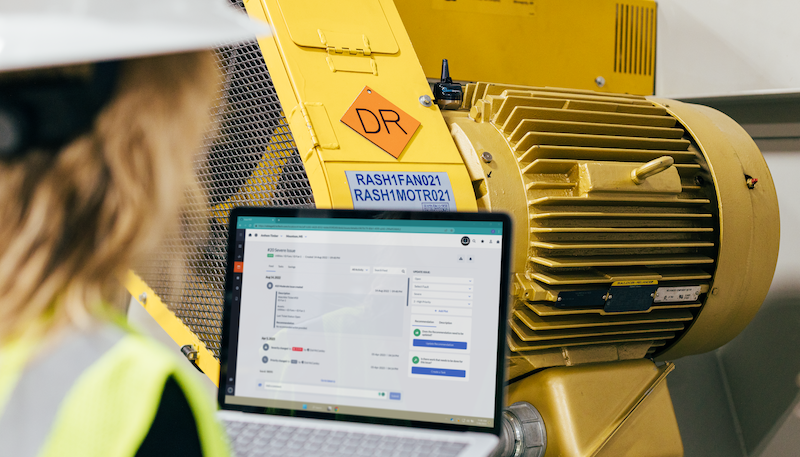

Severity and frequency of equipment failure in midstream operations is often undetectable to operators. Using a new approach with continuous real-time vibration monitoring will detect failure modes and early wear immediately.

Equipment failure causing downtime in downstream operations can cost hundreds of thousands of dollars. With continuous real-time vibration monitoring, operators are able to remotely compare readings with working equipment.

Russell Whitney

Global Innovation Manager

Precision Drilling

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

Discover how SMARTdiagnostics DeskAI identified issues in scrubber motors, helping optimize cleaning operations for greater productivity and performance.

SMARTdiagnostics flagged rising vibration on a vacuum pump, leading to inspection and ultimately replacement as the most cost-effective solution.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.