Catching Lubrication Failures Before They Derail Production

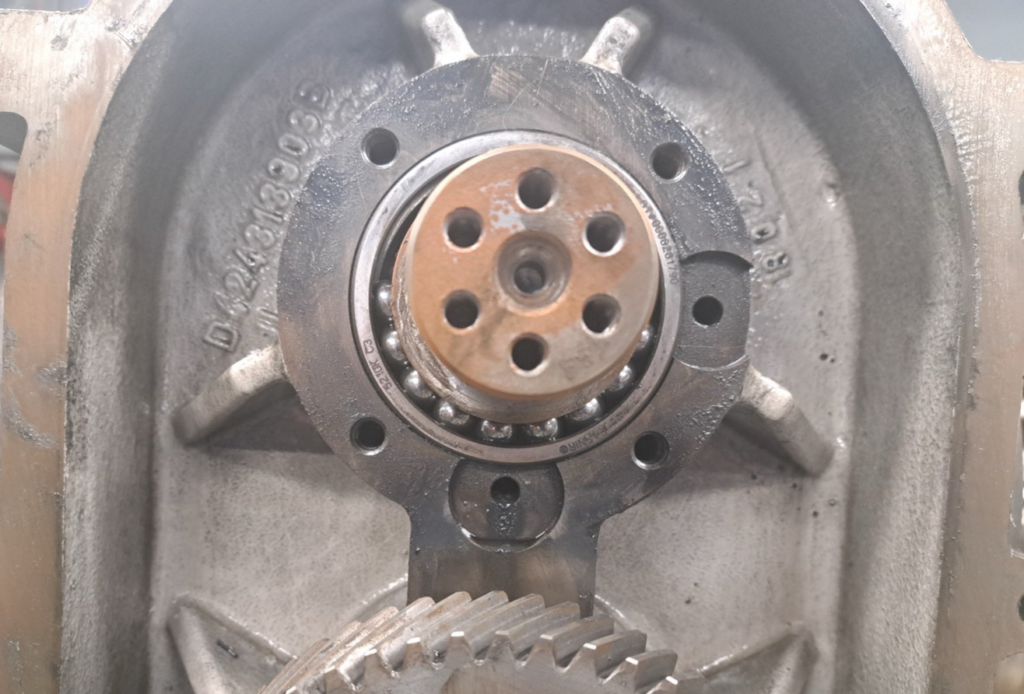

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

See how KCF helps you maximize operating efficiency and reduce safety issues

Screens and shakers are essential equipment for keeping mining operations running, yet the average facility suffers up to 30 failures per year for this asset type.

Pumps are the key to maintaining throughput in a mining operation, but they frequently fail due to the harsh conditions in which they operate and the difficulty of monitoring their health.

Baghouse fans keep production areas free of airborne fine particulate matter that can threaten the health and safety of your employees. The average baghouse fan fails up to 10 times per year.

Frac sand mining operations rely on drying kilns to complete the critical final step in the production of sands used in paving. The trunnion bearings that keep them moving have to work constantly, increasing their rate of failure.

Jaw crushers and mills are used to break mine products into standard discharge sizes. Naturally, crushing ore causes high levels of wear and tear on these assets, and they’re difficult and often unsafe to monitor.

Bearing defects, clutch failures, and bent pulleys all contribute to conveyor system failures which can bring production to a standstill. Belt conveyor failures can also threaten worker health and safety.

Induced draft fans are crucial to the mining industry. Failures on these assets can be costly as it can take a considerable amount of manpower to replace. Unexpected downtime from an induced draft air fan can get expensive, very fast.

Gearbox failure is one of the most common reasons for malfunctions and production loss. In the mining industry, gearbox failures can lead to unplanned downtime, lost production and costly damage to connected equipment.

In environments with such harsh conditions, most predictive technologies fail. Perhaps the most obvious example of this are the vibrating screens found in mining operations around the globe. Despite these realities, KCF Technologies is uniquely positioned to monitor and identify developing failure modes on vibrating screens thanks to a few key components.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Vacuum pumps are critical in many manufacturing processes. KCF's comprehensive machine health monitoring empowers you with the data and insights needed to minimizing unplanned downtime.

Overhead cranes are the lifeblood of several industries in manufacturing and are of extreme criticality. For many facilities, unplanned downtime on a crane could mean a complete halt of all production, resulting in massive expense.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven machine health platform can optimize your operations.