Overfire Air Fan

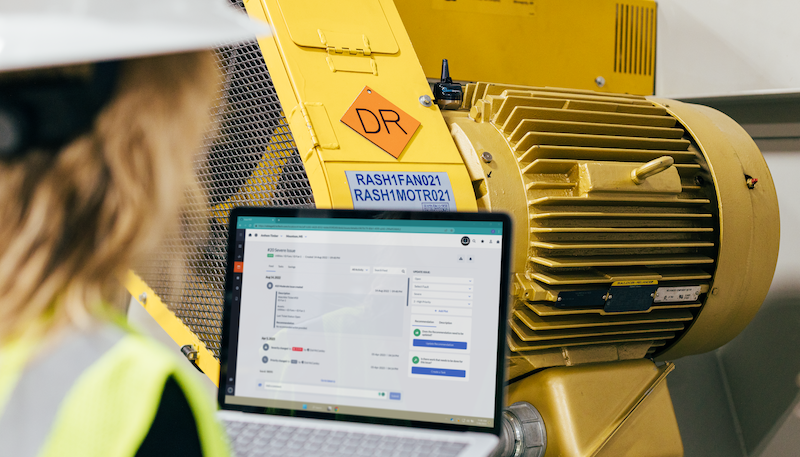

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

See how KCF helps you maintain production output and quality standards

Combustion fans are critical for many processes in the metal production industry. Continuous monitoring can prevent failures of fan wheels, belt/sheave/alignment, and bearings.

In metal production, piston pumps supply pressure for a variety of vital operations. Equipment failure can result in safety hazards and expensive downtime.

If a failure occurs at a tension reel—where steel is rolled into a coil at the end of the line—production will grind to a halt. Costly downtime can be minimized with predictive analysis.

Proper control of excess contaminants through dust collection systems is vital to a clean, safe, and efficient manufacturing process. Failures on these dust collection systems can lead to lengthy downtime and incur unnecessary costs.

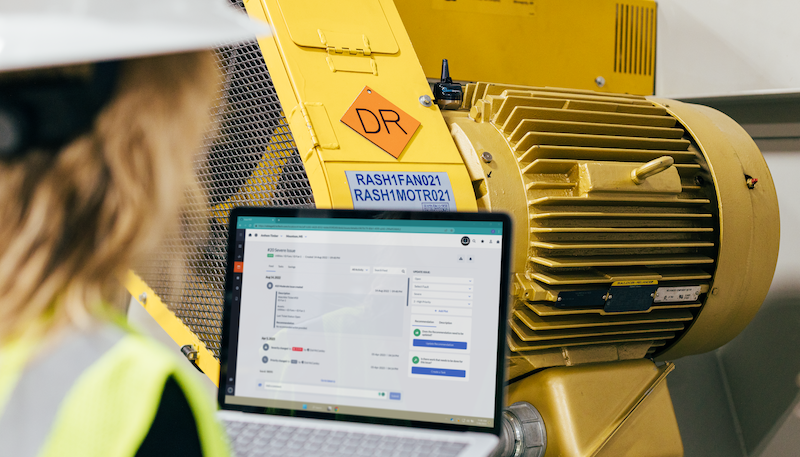

In metal production, having up-to-date information is critical for decision-making and planning processes, but that information does not generally move to decision-makers quickly enough to leverage its full value.

Unexpected gearbox failures can halt production, cause costly downtime, and pose safety hazards. Maintaining optimal gearbox health through proper monitoring and targeted maintenance maximizes their availability and ensures operational efficiency.

Many mills rely on steam turbines for power, making cooling tower fans crucial assets. Continuous monitoring of these large cooling fans enhances plant efficiency, reduces downtime, and supports effective maintenance practices.

Although cooling towers are a simple asset, their downtime can be detrimental to production efficiency. Loss of a cooling tower results in hours of unnecessary unplanned downtime.

Looper cars are essential for maintaining a continuous process, operating consistently unlike the tension and payoff reels. They play a critical role in a continuous finishing line by ensuring uninterrupted operation. A failure in a looper car can result in a downtime of up to 22 hours.

At first glance, cranes can be intimidating, but as with everything, they can be broken down into simple components to effectively monitor their health. A crane is just a collection of motors, gearboxes, and bearings. The challenge is that these components operate intermittently and almost never make the exact same motion repeatedly. From a monitoring perspective, this has made cranes nearly impossible to extract valuable machine health data.

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

Discover how predictive maintenance transforms the metals industry, enhancing efficiency and reducing costs for better performance.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.