Watch to learn how predictive maintenance is transforming the glass manufacturing industry.

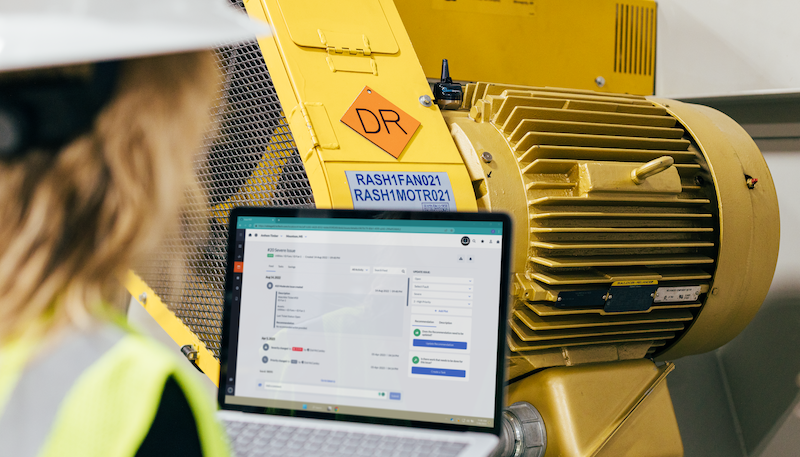

Overfire Air Fan

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

See how KCF helps manufacturers improve efficiency and maintain compliance

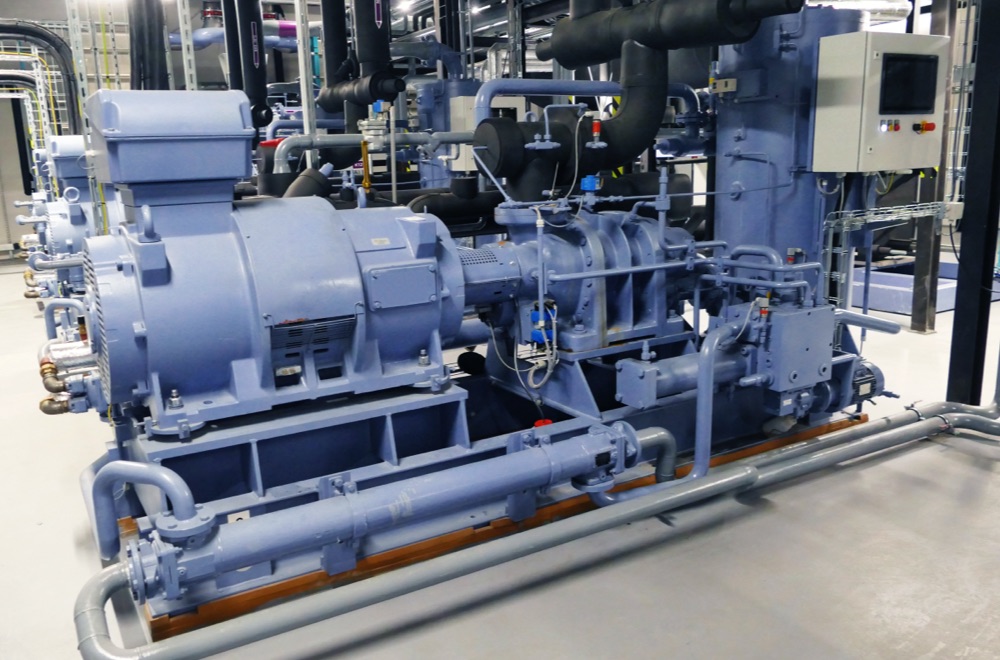

Ammonia compressor maintenance is strictly regulated by agencies like OSHA. This asset needs to be monitored regularly, but route-based vibration monitoring is expensive and doesn’t tell the whole story.

Any delays at the filling step can impact production all the way down the line. Bottle filling lines contain a number of different assets and components, making it difficult to assess the overall health of the line.

These critical assets can be difficult to maintain, as homogenizers are often inaccessible due to guarding and have to process ever-changing mixes that impact their operating conditions.

Multiple production processes can be shut down when a cooling tower can no longer efficiently dissipate excess heat. Rising temperatures threaten product integrity, adding the price of spoilage to the total cost of a failure event.

Watch to learn how predictive maintenance is transforming the glass manufacturing industry.

Glass packaging leader builds momentum in just 30 days.

When Anchor Glass’s Warner Robins, Georgia plant engaged in KCF Technologies’ pilot program, they weren’t just looking for another maintenance tool—they wanted proof of a smarter, more proactive way to protect critical assets. And that’s exactly what they got.

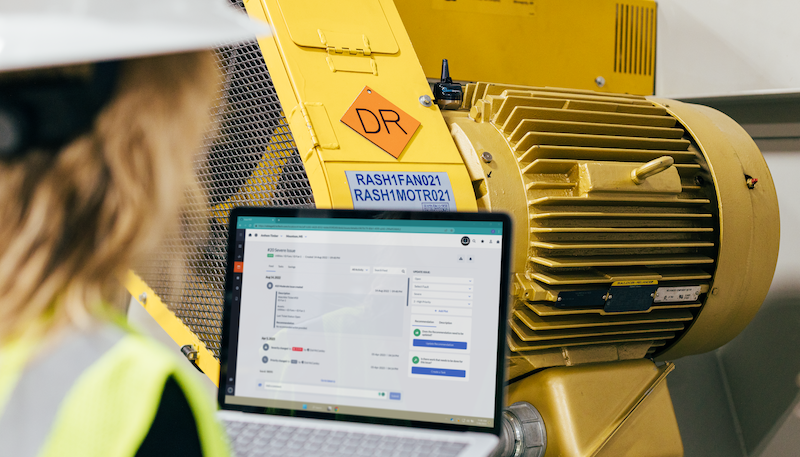

SMARTdiagnostics ingests signals from a range of sensor types — including third-party sensors — to detect early fault warning signals that vibration sensors alone won’t catch. Automated analytics capabilities put advanced machine health knowledge in your team’s hands from day one.

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

Discover how predictive maintenance enhances efficiency in the food and beverage industry, ensuring quality and reducing downtime.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.