Prabhu Ramachandran

Digital Transformation Project Manager

Kaneka

Overfire Air Fan

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

See how KCF helps you prevent critical failures and enhance reliability

Agitator processes, whether vertically or side-mounted, are sporadic. Backlash in the gearbox stresses brackets and couplings. Without continuous monitoring, reliability programs may miss key insights, leading to costly failures and downtime.

Canned pumps are vital in the Petrochemical industry for transferring hazardous liquids, with enclosed bearings that don’t require regular lubrication. Continuous monitoring is essential, as journal bearings can fail within 48 hours, making monthly inspections inadequate.

Blowers are crucial in the Acid Regeneration process, and maintaining assets like Turbo Blowers is essential but challenging. Downtime can halt production, with failure modes varying by process configuration.

Cooling towers pose challenges for accessibility and monitoring, causing many maintenance professionals to overlook critical signs of impending failure. Such failures can disrupt various production processes downstream.

Dryer blowers are vital in the chemical industry for removing moisture from products. Induced and forced draft fans provide a steady flow of hot air, facing challenges like blade corrosion and imbalance from material buildup, leading to premature bearing or asset failure.

Screw compressors are essential for air supply and gas storage. Failures, often due to bearing issues, shaft misalignment, or lubrication problems, halt operations by losing high-pressure fluid. Optimizing running speeds is key to minimizing downtime.

Air compressors in a plant can cause significant energy waste and costly downtime due to unexpected failures. Air leaks increase demand, leading to higher energy use and more wear on compressor components.

Prabhu Ramachandran

Digital Transformation Project Manager

Kaneka

In today’s fast-changing manufacturing world, adopting digital transformation has become a vital strategy for companies striving to stay competitive. Beyond the buzz of technology and data-driven solutions, a crucial yet often overlooked aspect is the significant role that cultural change plays. Prabhu Ramachandran, a visionary leader and member of Kaneka’s Digital Transformation (DX) team, is at the forefront of driving this essential shift in the IIoT production and manufacturing space.

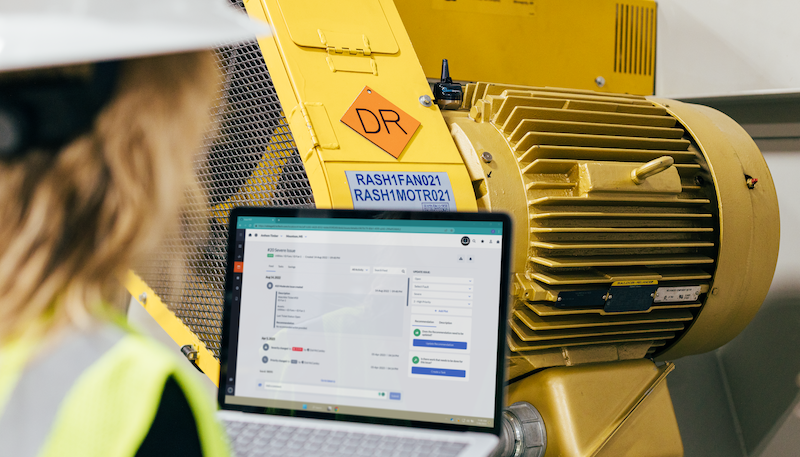

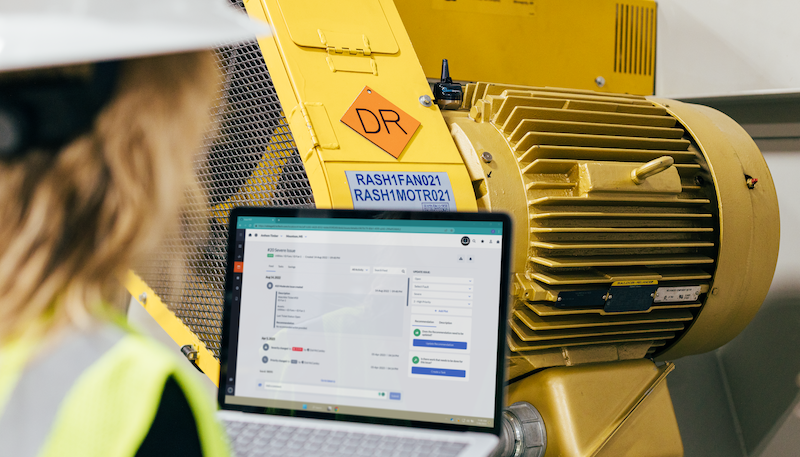

Our comprehensive machine health platform, wirelessly and continuously transmits machine health data to a central database from individual monitoring points on your assets. Its advanced analytics capabilities get to the root cause of machine health issues, and its human-in-the-loop architecture ensures compliance and correct action.

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

How predictive maintenance drives safer and more reliable operations in the chemicals industry.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.