Revolutionizing Predictive Maintenance in the Automotive Industry

Discover how predictive maintenance transforms the metals industry, enhancing efficiency and reducing costs for better performance.

See how KCF helps you meet production quotas and quality standards

In the fast-paced environment of a stamping shop on the production line in the auto industry, maintaining seamless operations is crucial. Predictive maintenance uses advanced technologies to monitor machine health and detect issues early, preventing major breakdowns. This proactive approach reduces unplanned downtime and extends machinery lifespan, ensuring efficient production.

In the dynamic body weld shop of an automotive assembly line, smooth operations are essential. Robotic welders and other machinery are critical for assembling vehicle frames. Predictive maintenance monitors equipment health to detect issues early, minimizing downtime and extending machine lifespan for efficient production.

In a busy automotive paint shop, maintaining continuous operation is crucial for a flawless finish. Fans, lifts, pumps, and conveyance systems are essential for efficient painting and drying. Predictive maintenance detects equipment issues early, reducing downtime and enhancing machine longevity. This proactive approach ensures smooth, efficient production and consistent quality.

In a powertrain shop on an automotive assembly line, uninterrupted operation is crucial for precision and efficiency. Key equipment like engines, transmissions, and drive systems must work flawlessly. Predictive maintenance detects issues early, reducing downtime and extending machinery life, ensuring reliable and efficient production.

In a general assembly shop on an automotive production line, seamless operations are vital. Equipment like conveyors, robotic arms, and fastening tools must function perfectly. Predictive maintenance identifies issues early, reducing downtime and extending equipment life. This proactive approach ensures efficient, reliable production and high-quality output.

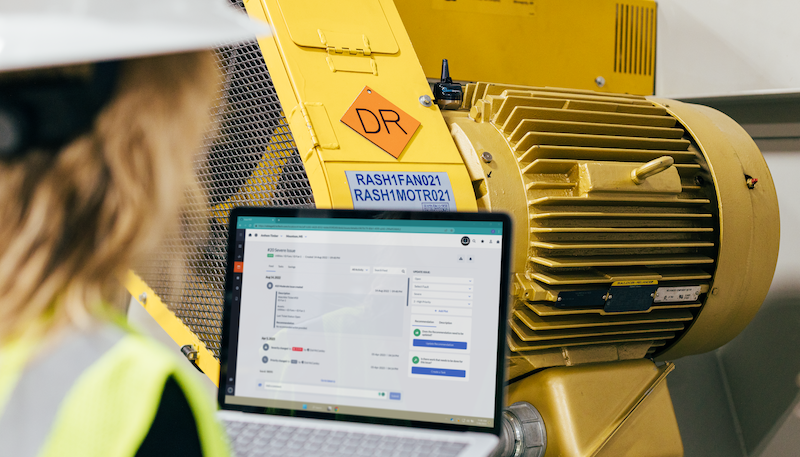

The platform will alert maintenance professionals to assets that need attention, so that crews can act in a targeted fashion during those narrow windows of time available for maintenance. This allows your maintenance team to go straight to the machines that need help instead of using critical plant time to perform ineffective PMs on machines that are functioning properly.

These (and many other) questions can only be answered with the insight provided by a holistic machine health optimization platform.

Drive process improvements in your plant with advanced analytics, expert insight from engineers with automobile industry experience, continuous asset monitoring and analysis, and predictive maintenance support.

Discover how predictive maintenance transforms the metals industry, enhancing efficiency and reducing costs for better performance.

Learn how KCF Technologies optimizes overfire air fan performance through SMARTdiagnostics real-time monitoring.

A railcar leader partnered with KCF Technologies and FUCHS. SMARTdiagnostics™ flagged oil-related gearbox issues—38% of alerts were lubrication-related.

Want to eliminate unplanned downtime and extend the lifespan of your critical assets?

Contact us to see how our comprehensive, AI-driven predictive maintenance platform can optimize your operations.