Vacuum pumps are critical in many manufacturing processes, providing the essential vacuum environment needed to produce high-quality products.

KCF Technologies’ Comprehensive Machine Health Platform empowers maintenance and reliability teams with the data and insights necessary to perform condition-based monitoring, reducing unnecessary time-based PMs and minimizing unplanned downtime. KCF’s wireless High-Definition vibration sensor transmits full spectrum, biaxial vibration, and temperature readings up to once a minute, providing real-time information on the health of vacuum pumps.

Traditionally, maintaining vacuum pumps relied on time-based preventive maintenance and replacing pumps upon failure. However, this approach is costly when factoring in downtime and lost production due to vacuum system failure. To optimize maintenance practices, manufacturers are shifting from reactive maintenance to condition-based monitoring.

With condition-based monitoring, KCF’s platform can detect issues such as contaminated oil, bearing wear, belt wear, motor looseness, and many other fault modes. This proactive approach ensures that potential problems are identified and addressed before they lead to costly failures, enhancing the efficiency and reliability of manufacturing operations. By transitioning to condition-based monitoring, manufacturers can achieve significant cost savings, improve product quality, and ensure continuous production.

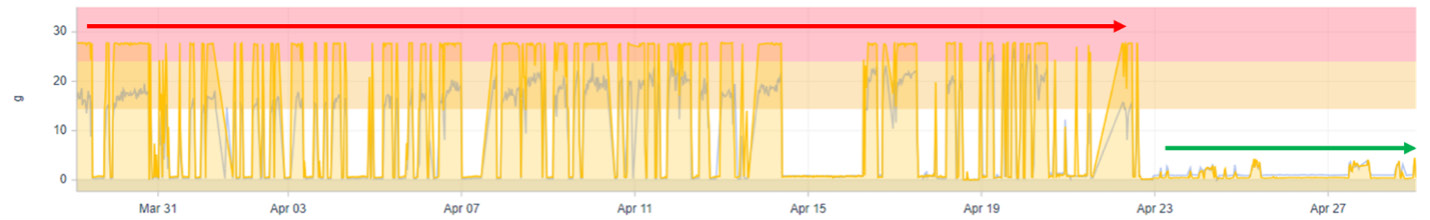

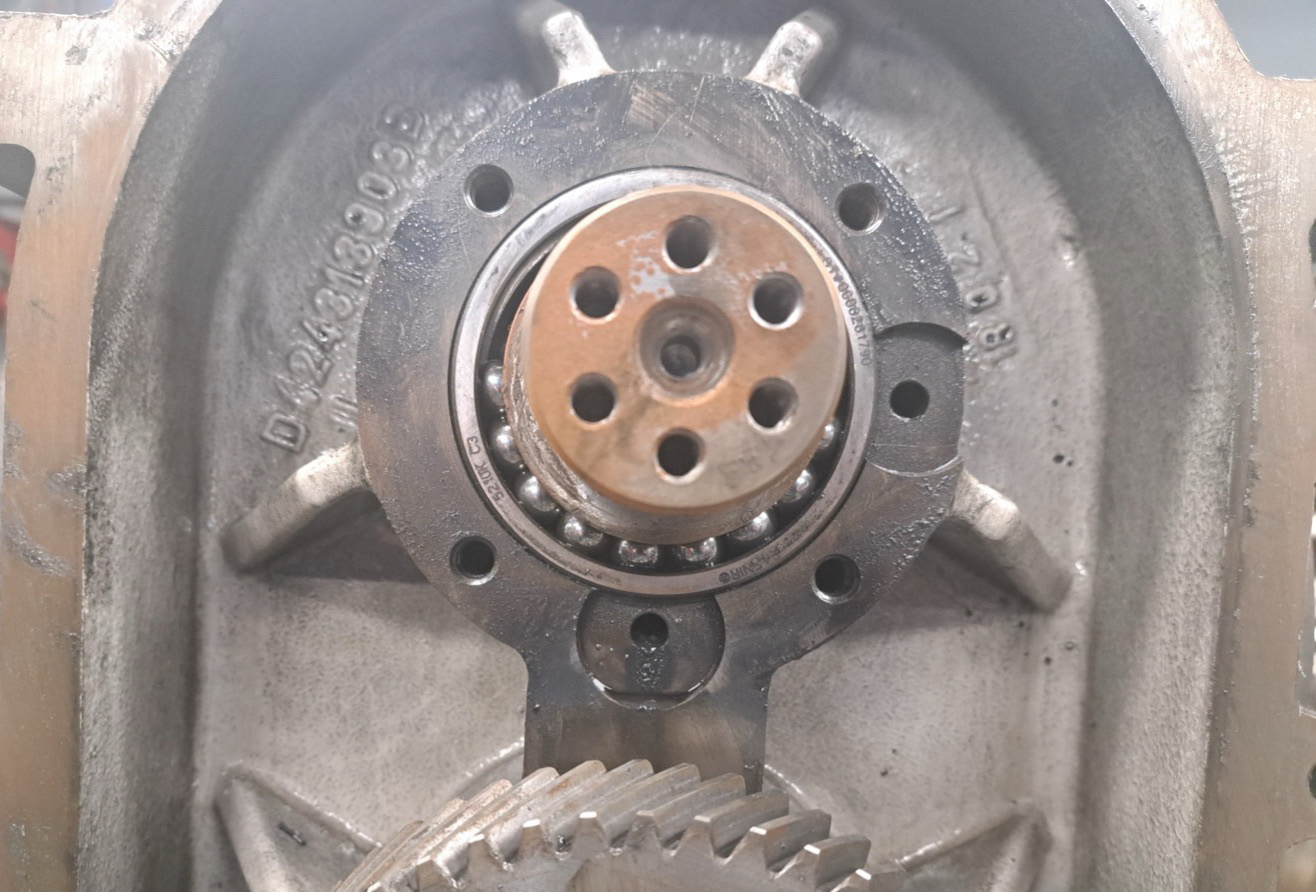

In one instance, a Stokes 412 vacuum pump that had been running healthy developed a rapid increase in the peak acceleration vibration. The site was notified by KCF, and the flywheel was inspected at the next planned downtime opportunity. That inspection allowed the site to identify and fix the flywheel taper lock. Fixing the vacuum pump in a planned state prevented unplanned downtime and potential injuries associated with reactive maintenance. When made in a scheduled state, the repair was made in a matter of minutes instead of the hours it would take without the data indicating the fault mode.

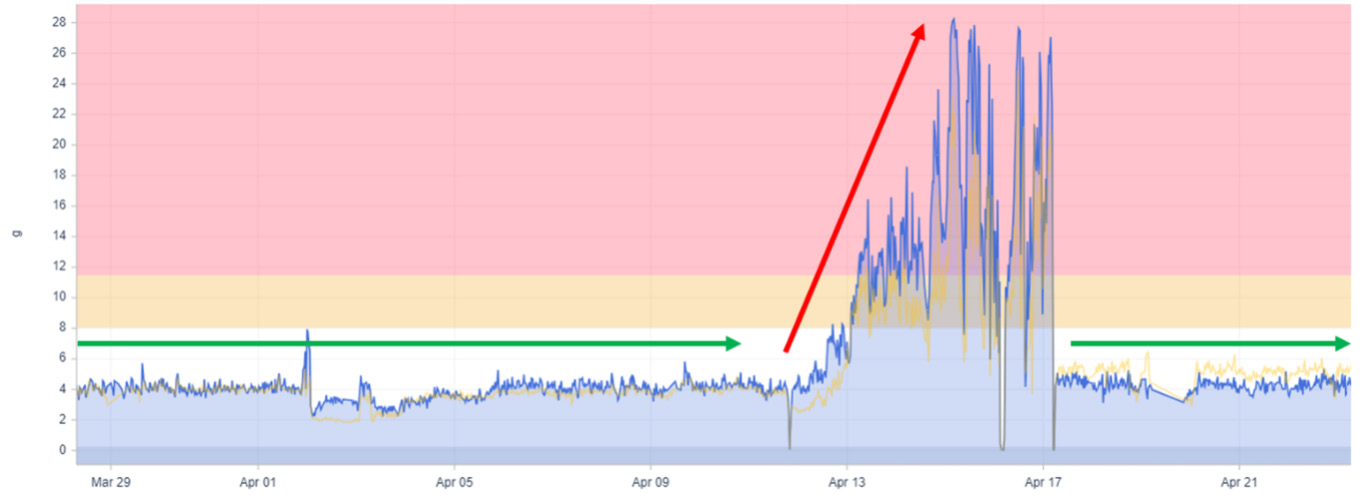

In another instance, upon installation of KCF’s sensors, a vacuum blower was called out for an outboard bearing issue. The site was able to take the time to do further analysis since this technology was new. During a traditional pump inspection, no anomalies were detected, and the blower continued to run. After more analysis, KCF continued to recommend a pump-bearing replacement. The site was able to shut down the pump in a planned state and found the outboard bearing to be in complete failure. A new pump was installed, and they were back in operation without any unplanned downtime.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.