The Problem

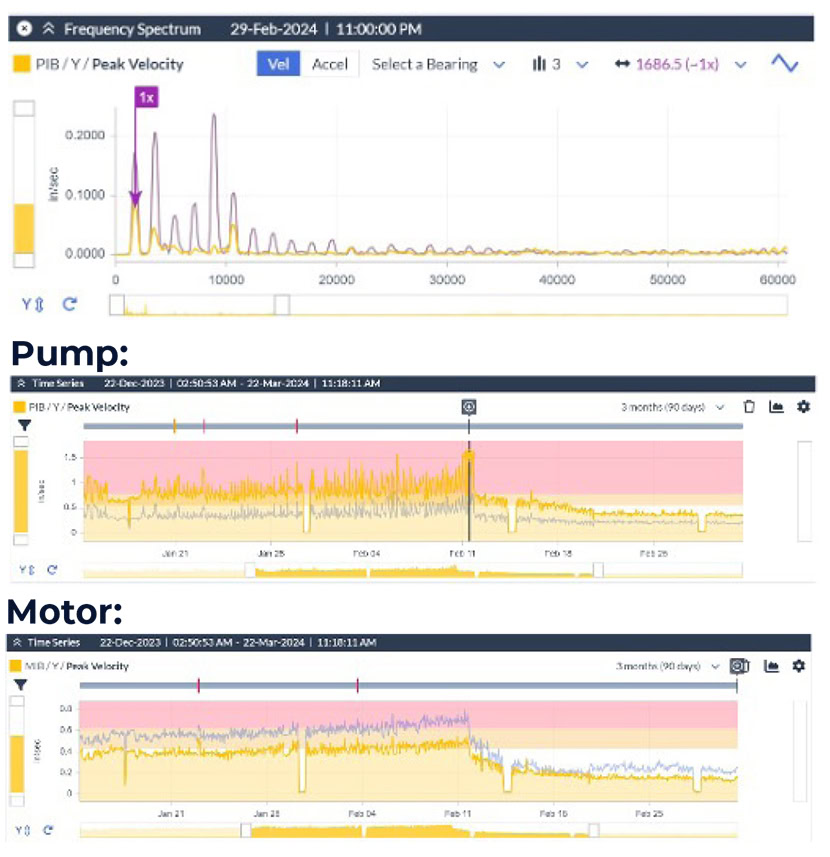

A KCF analyst saw signs in the frequency spectrum leading them to believe there was looseness present in this vacuum pump. Once the asset was able to be inspected, a bad coupling element was found that was causing the looseness in the pump.

How we solved it

Following alignment and the coupling replacement, levels immediately returned to a healthy point and have stayed there since.

$36,000

Cost of New Pump

6 hours

Downtime Avoided

Ready to Take the Next Step in Your Machine Health Journey?

Let’s Get in Touch.Email: [email protected]

Phone: 1 (814) 867-4097 Ext. 1

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.