The Problem

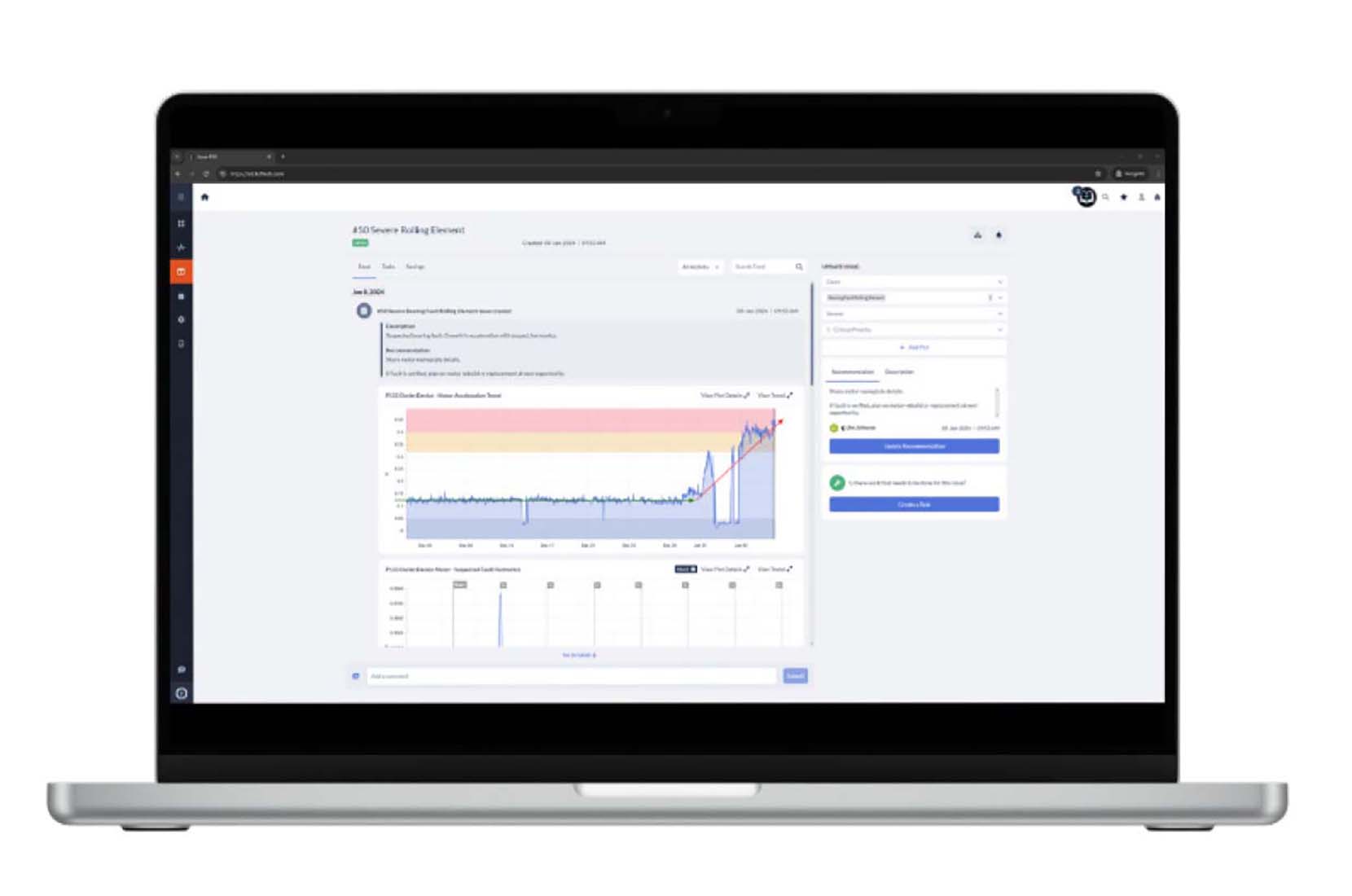

This motor on this Trim Blower Fan was showing an increase in vibration in the lower frequency, most likely caused by imbalance. It was recommended in SMARTdiagnostics to clean the fan blades, to check the fan for imbalance and then balance the fan during the next scheduled downtime. Upon inspection, imbalance was discovered.

How we solved it

Prompt action was taken to shut down the fan, preventing further damage and initiating repair procedures offsite. Despite a two-week repair period during which operations continued at reduced capacity, this preemptive measure was crucial. Without intervention, a failure would have necessitated a custom replacement, potentially disrupting operations for up to six months due to the bespoke nature of the equipment.

$16,572

Repair and Maintenance

29 hours

Downtime Avoided

Ready to Take the Next Step in Your Machine Health Journey?

Let’s Get in Touch.Email: [email protected]

Phone: 1 (814) 867-4097 Ext. 1

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.