1

Case Study

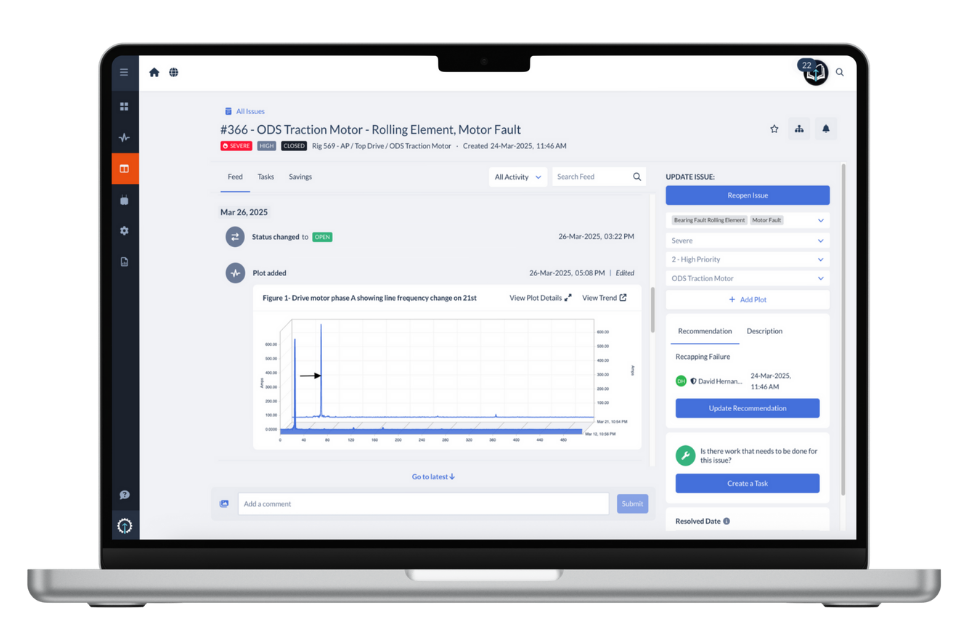

SMARTdiagnostics detected a sharp rise in peak acceleration on a Top Drive traction motor—from 4.3g to 24g over a weekend—indicating a potential fault. Layered with Motor Current Signature Analysis (MCSA) data, the findings showed a clear link between the vibration increase and higher motor speeds, highlighted by a line frequency jump from 24.75 to 49.5 Hz.

SMARTdiagnostics and MCSA data revealed that a spike in motor acceleration from 4.3g to 24g over a weekend was directly linked to increased motor speed, as shown by a line frequency rise from 24.75 to 49.5 Hz.

A proactive inspection confirmed early-stage bearing wear on the traction motor, allowing the customer to repair it before failure and save $85,000.

By integrating vibration and MCSA data into one platform, SMARTdiagnostics enabled the customer to quickly detect, confirm, and address a developing fault, preventing failure and ensuring it would not recur.

The Problem

SMARTdiagnostics called out a potential motor fault on this Top Drive traction motor due to an increase in peak acceleration levels from 4.3g’s to 24g’s over a weekend. While the vibration data painted one picture, adding trending Motor Current Signature Analysis (MCSA) data enabled the team to dive even deeper into the potential cause.

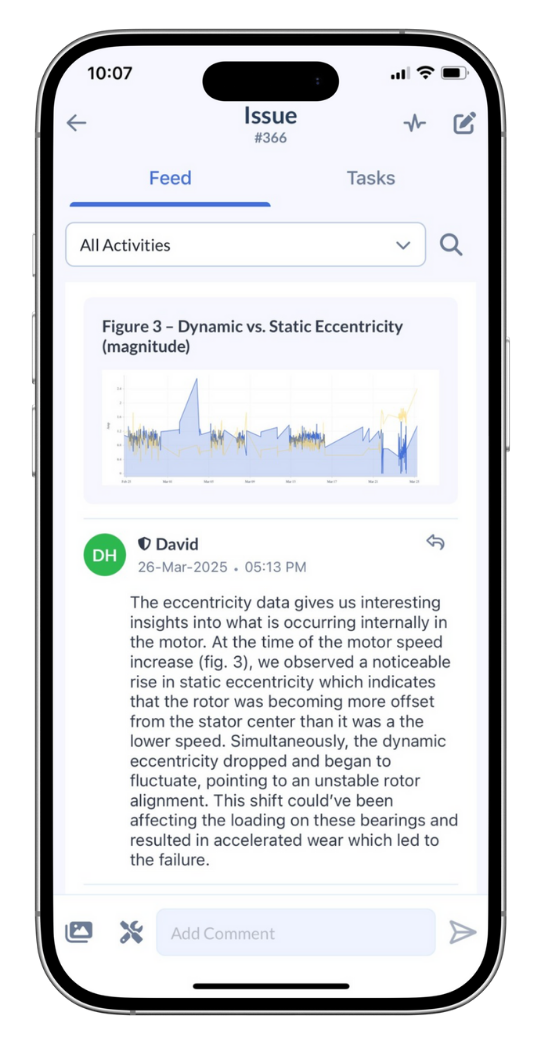

Looking at the layered vibration data with the trending MCSA data, it was clear there was a direct correlation between the increase in peak acceleration and the running speed of the motor. An increase in line frequency from 24.75 to 49.5 Hz supplied by the MCSA hardware, easily highlighted when motor step changes occurred, and it was clear that vibration increased when speed increased.

Detection

SMARTdiagnostics called out a potential motor fault on this Top Drive traction motor due to an increase in peak acceleration levels from 4.3g’s to 24g’s over a weekend.

While the vibration data painted one picture, adding trending Motor Current Signature Analysis (MCSA) data enabled the team to dive even deeper into the potential cause.

Looking at the layered vibration data with the trending MCSA data, it was clear there was a direct correlation between the increase in peak acceleration and the running speed of the motor. An increase in line frequency from 24.75 to 49.5 Hz supplied by the MCSA hardware, easily highlighted when motor step changes occurred, and it was clear that vibration increased when speed increased.

The Response

Predictive Maintenance for Proactive Inspection

With the issue confirmed across both vibration and electrical channels, the customer scheduled a proactive inspection of the traction motor. The investigation verified early-stage bearing wear, and the customer repaired the bearing before the asset could fail, leading to $85,000 in savings.

$85,000

in Customer Savings

The Outcome

Bringing Insights Together for Proactive Action

This asset failure prevention highlights the importance of a comprehensive machine health solution that can take in many sensor types, such as vibration and the KCF MCSA hardware solution, to understand the complete story your machine health data is telling you.

While most predictive maintenance systems require separate mechanical and electrical analysis platforms, the SMARTdiagnostics comprehensive machine health platform brought these insights together, making it easy for the customer to act confidently and quickly.

Using SMARTdiagnostics, this customer could detect and validate the developing fault from multiple perspectives to prevent a failure and have the data to eradicate the potential failure from occurring again.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.