1

Case Study

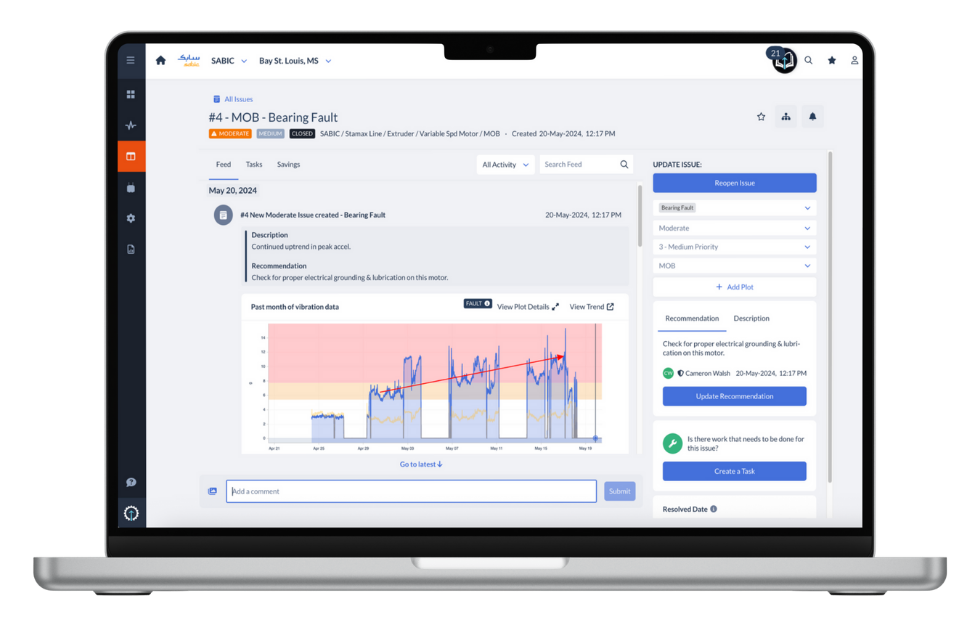

In high-output extrusion, downtime is costly. At SABIC’s Bay St. Louis plant, KCF’s SMARTdiagnostics caught abnormal motor behavior shortly after a filter change. A sensor flagged rising acceleration, triggering an alert that enabled analysts to act before the issue escalated.

A KCF analyst found rising acceleration, high-frequency noise, and impacts consistent with bearing distress, recommending checks on grounding and lubrication.

SABIC traced rising motor strain to a clogged sock filter and recent product change, both contributing to abnormal vibration. Thanks to SMARTdiagnostics, they resolved the issue early, avoiding failure, emergency downtime, and an estimated 8 hours/$107,000 in losses.

This complex issue, triggered by maintenance and masked by a product change, could have gone unnoticed. SMARTdiagnostics turned subtle vibration signals into clear action—protecting uptime and saving six figures.

KCF Technologies X SABIC

In high-output extrusion environments, unplanned downtime isn’t just inconvenient— it’s expensive. Every minute of lost production can mean lost production, material waste, and significant recovery costs. That’s why manufacturers like SABIC rely on continuous monitoring to keep operations running smoothly.

Routine maintenance doesn’t always mean routine outcomes. Shortly after a filter change on one of their extruder lines, a subtle shift in motor behavior hinted at a deeper issue—one that KCF Technologies’ SMARTdiagnostics platform caught before it could escalate.

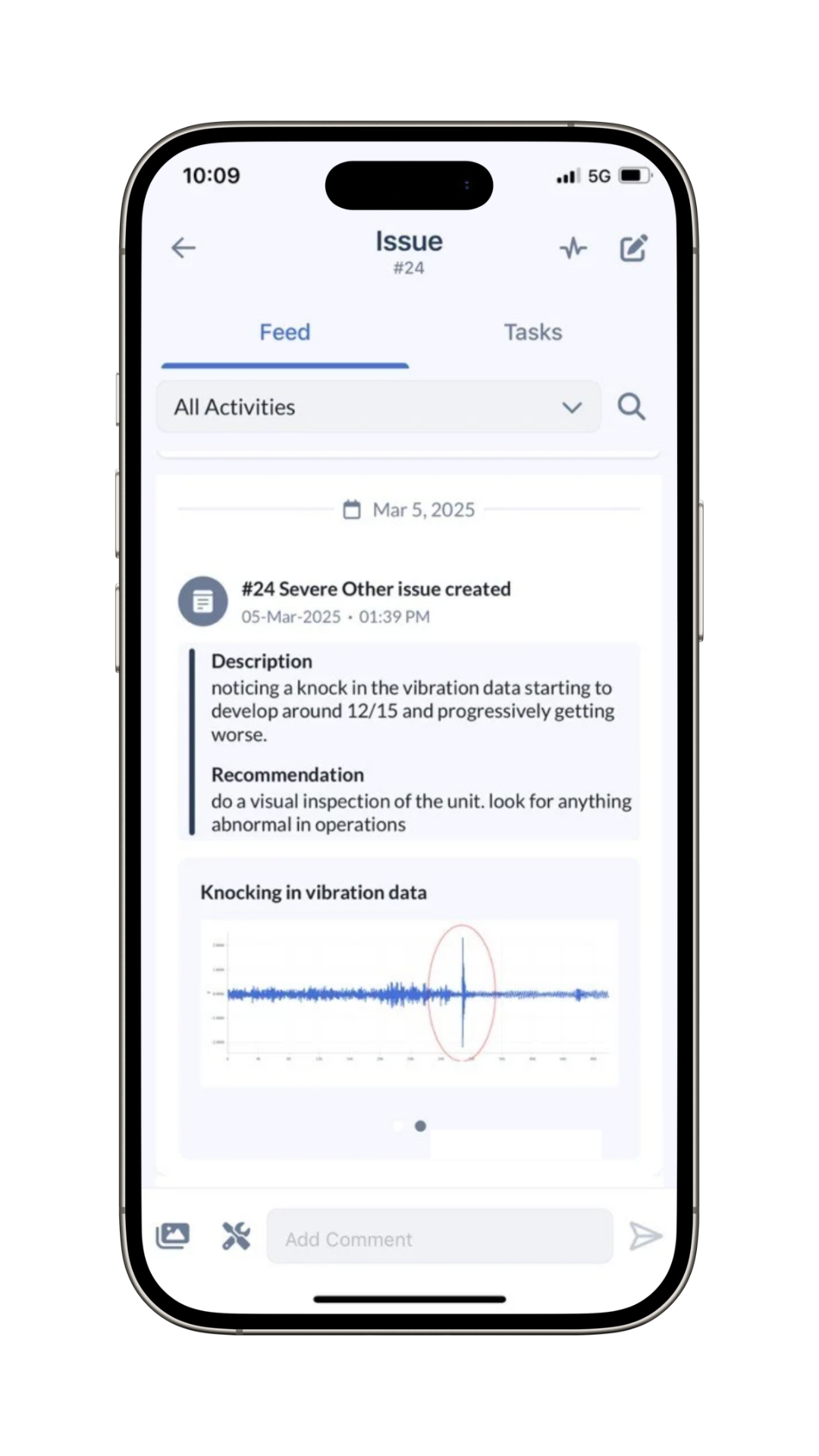

A sensor on the outboard side of a variable speed motor at SABIC’s Bay St. Louis, Missouri location, detected a rise in peak acceleration. SMARTdiagnostics flagged the trend and automatically generated a fault alert, prompting a KCF analyst to investigate further.

Diagnosing a Hidden Issue:

The KCF certified vibration analyst reviewed three key plots to better understand the condition of the motor:

Trend Plot: One month of vibration data showed a steady upward climb in peak acceleration—clear evidence of a worsening condition.

Waterfall Plot: Revealed increasing highfrequency noise, typically associated with electrical disturbances or mechanical strain.

Time Domain Plot (Machine Voice): Using the Machine Voice feature, which allows users to actually listen to vibration data, the analyst identified harsh impacts consistent with “footballing”—a strong indicator of bearing distress, likely tied to poor lubrication or increased load.

Based on these findings, the analyst recommended checking the motor’s electrical grounding and lubrication.

What SABIC Discovered:

SABIC confirmed that they had recently performed time-based maintenance, including installing and replacing a sock filter—a fabric-style filter used to capture material contaminants. Over time, the filter had become packed with material, which restricted flow and forced the motor to work harder to maintain throughput. That added strain was transferred directly to the motor’s bearings.

Complicating matters further, the site had also recently changed product types on the line, a transition that can shift operating conditions and contribute to unusual vibration signatures. Despite the layered nature of the issue, the SMARTdiagnostics alert and follow-up analysis helped SABIC trace the problem back to its true source.

With early visibility into the fault and a clear path to resolution, SABIC took corrective action before the asset failed. The motor remained operational, no emergency downtime was required, and production stayed on track.

The team avoided an estimated 8 hours of unplanned downtime, equating to $107,000 in monetary savings and reactive repair costs by catching the issue when they did.

Why it Matters:

This wasn’t a textbook failure mode. It was a layered mechanical issue, set off by regular maintenance and masked by a product change—something that could have easily gone unnoticed until it was too late. But SMARTdiagnostics gave SABIC the clarity to act fast.

From AI-powered fault detection to machine listening diagnostics, the system transformed subtle vibration signals into meaningful action—protecting uptime and saving six figures in the process.

$107,000

in Downtime Avoided

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.