Revolutionizing Predictive Maintenance in the Mining Industry

KCF Technologies is the Ultimate Predictive Maintenance Partner

Introduction

Mining operations are the lifeblood of countless industries, supplying critical materials for manufacturing, energy, construction, and more. However, the demanding environments and heavy-duty equipment inherent to mining present constant challenges to maintaining uptime. Unexpected asset failures can lead to costly downtime, lost production, safety risks, and expensive repairs.

KCF Technologies is reshaping the future of mining maintenance with SMARTdiagnostics®, a predictive maintenance platform that combines real-time machine health monitoring with expert-driven analytics. By empowering mining operations to identify developing faults early, KCF helps prevent failures before they occur, enhancing safety, reducing downtime, and maximizing operational efficiency.

The Impact of PdM

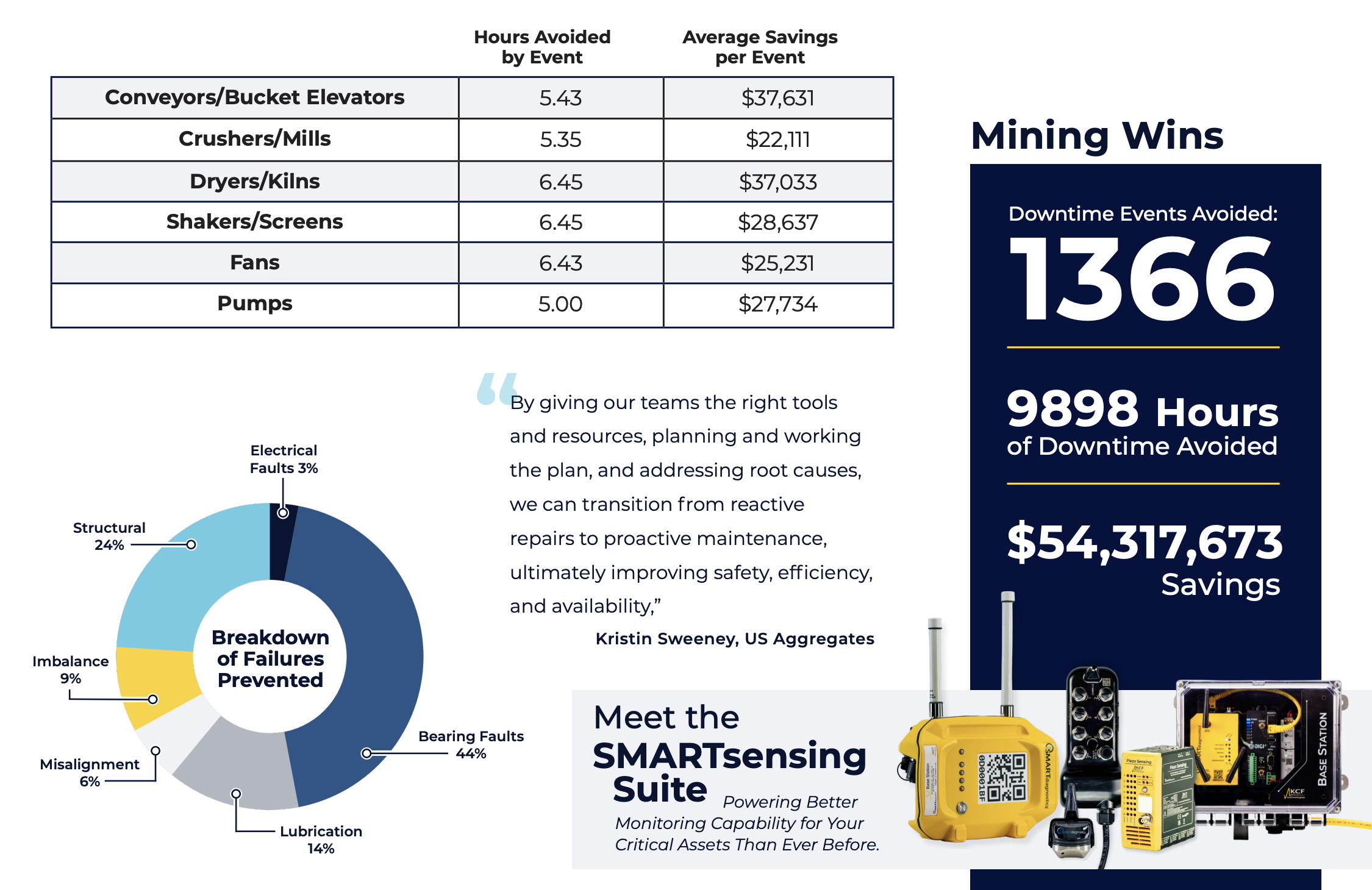

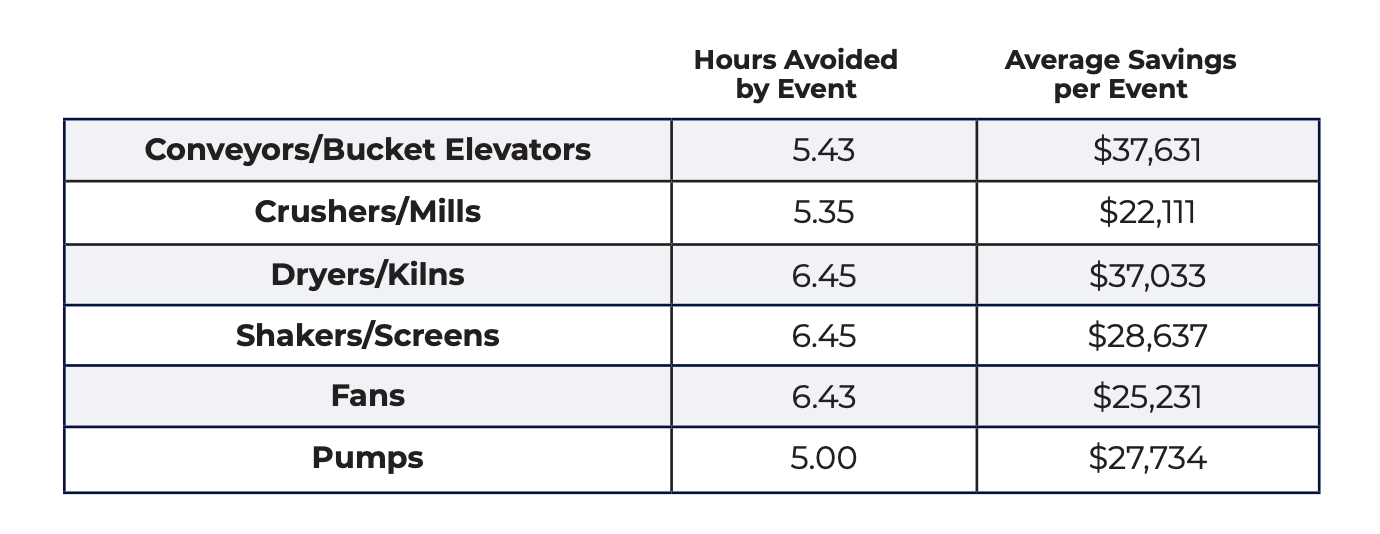

KCF Technologies’ predictive maintenance solutions have delivered significant results across the mining sector:

The outcomes are significant:

1,366

Downtime Events Avoided

9,898

Hours of Downtime Avoided

$54,317,673

Savings Realized

“By giving our teams the right tools and resources, planning and working the plan, and addressing root causes, we can transition from reactive repairs to proactive maintenance, ultimately improving safety, efficiency, and availability.”

Kristin Sweeney

US Aggregates

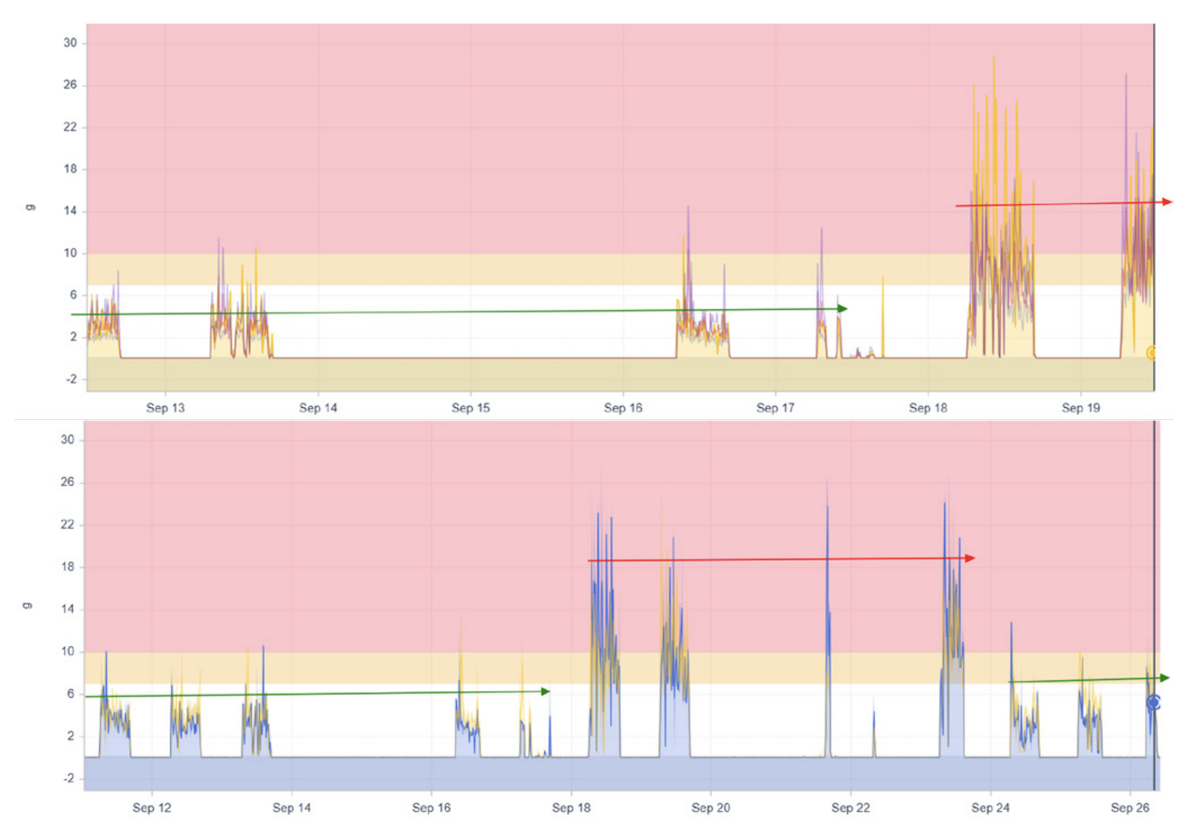

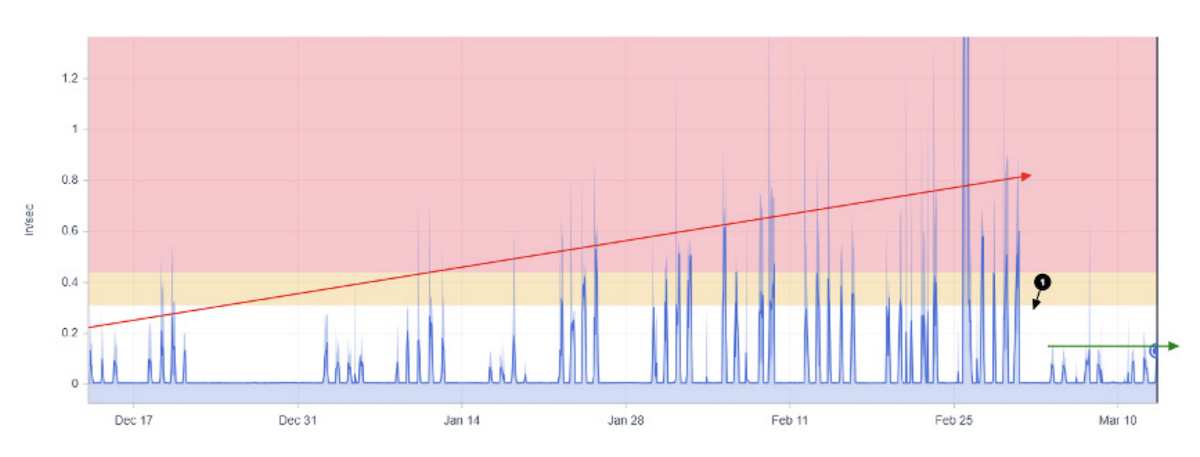

KCF's Superior Sensor Technology

Wireless vibration sensors are a crucial enabler of predictive maintenance, but not all sensors are created equal. Many solutions on the market suffer from poor design, resulting in false positives, missed diagnoses, and erosion of trust in condition monitoring programs. KCF Technologies has set the industry standard with its patented Version 3 High-Definition sensor, engineered for unparalleled accuracy and reliability.

Key Advantages of KCF’s Sensor Technology:

Minimal Measurement Error: KCF’s sensors exhibit less than 6% error, compared to the 60-410% error range of competing sensors. Patented Stability

Design: KCF’s vibration sensors avoid the instability issues found in many wireless solutions, ensuring accurate diagnostics.

Proven Reliability at Scale: Unlike many predictive maintenance startups, KCF Technologies has a track record of successfully implementing scalable monitoring solutions across industries.

Sensor Overview

KCF’s High-Definition Vibration Sensor offers industry-leading data acquisition—collecting the full spectrum of data as often as once every minute. Our unique ability to take high-interval, full-spectrum data allows for a best-in-class machine learning training dataset, delivering exceptional predictive maintenance analytics.

Mining Case Studies

Real-World Successes

1

Case Study

Primary Crusher: Motor Failure Prevention

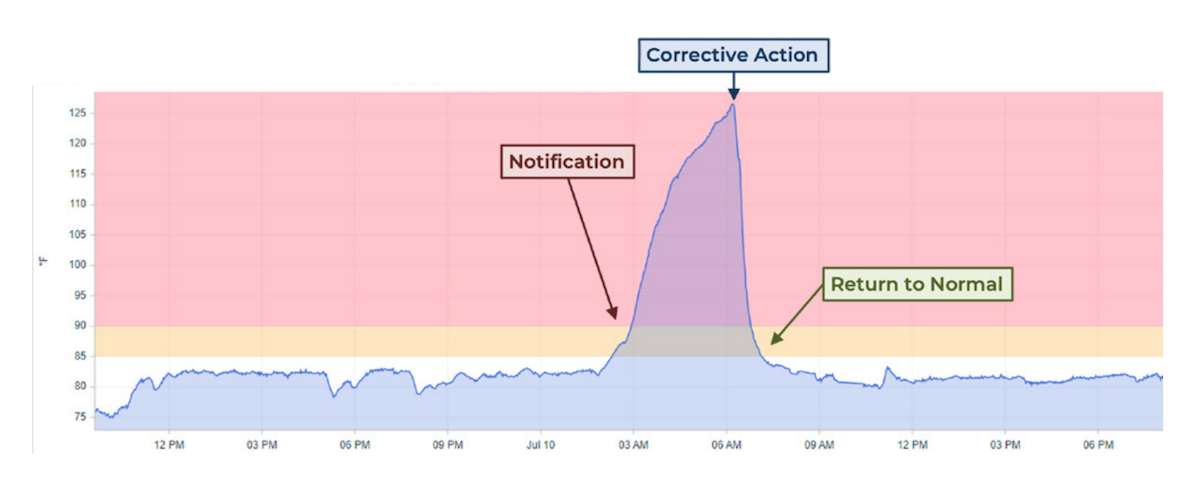

DETECTION: An early SMARTdiagnostics® alert identified a developing fault on a primary crusher.

ACTION: Upon inspection, the motor driving the feeder was found to be aging and producing audible noise. The customer replaced the motor during a planned shutdown.

IMPACT: This proactive repair prevented 4 hours of unplanned downtime.

2

Case Study

Secondary Crusher: Maintenance Error Correction

DETECTION: Following a recent repair, SMARTdiagnostics® detected abnormal behavior on a secondary crusher.

ACTION: Inspection revealed that electrical leads had been incorrectly reconnected, causing the crusher to run in reverse. The wiring was corrected.

IMPACT: The correction avoided 12 hours of downtime.

3

Case Study

Combustion Fan Imbalance

DETECTION: SMARTdiagnostics® detected a developing imbalance condition caused by dust accumulation on fan blades.

ACTION: A new maintenance schedule was implemented to regularly clean the blades.

IMPACT: This proactive measure prevented 32 hours of downtime.

4

Case Study

Sand Dredge Motor Issue

DETECTION: Continuous monitoring caught improper bearing installation on a recently replaced 500-hp motor.

ACTION: Early detection enabled a shutdown and correction while the asset was still under OEM warranty.

IMPACT: This prevented 226 hours of downtime.

Why Choose KCF Technologies?

KCF Technologies combines powerful sensor technology, expert engineering support, and real-time data analytics to deliver unparalleled predictive maintenance results.

Choosing KCF means gaining:

- Earlier Fault Detection: Stop failures before they escalate.

- Major Cost Savings: Avoid expensive repairs and downtime.

- Enhanced Worker Safety: Address issues before they become hazards.

- Reliable, Actionable Data: Industry-leading sensor precision.

- Optimized Equipment Lifespan: Extend asset health and boost productivity.

Conclusion

In mining, uptime is money. KCF Technologies empowers mining companies to achieve zero unplanned downtime, minimize safety risks, and maximize production output. By leveraging SMARTdiagnostics®, mining operations can move from reactive to proactive maintenance, gaining a decisive competitive advantage.

Learn how KCF’s machine health optimization platform will help you achieve peak plant performance at kcftech.com

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.