Revolutionizing Predicitive Maintenance in the Metals Industry

Introduction

The metals industry depends on consistent uptime. From mill stands to cranes, unplanned failures can bring production to a halt and create significant safety risks. In these high-load, high-temperature environments, even minor equipment issues can escalate quickly. Despite robust routes and preventive maintenance schedules, many failure modes, such as bearing faults, lubrication breakdowns, and electrical issues, often develop out of view.

Predictive maintenance helps solve these problems. By continuously monitoring machine condition and identifying early-stage faults, metals producers are reducing unplanned downtime, protecting critical, often aging assets, and safeguarding employees from the dangers associated with reactive maintenance and unexpected failures.

Industry-wide Results

*all figures as of 2025

The results are clear:

Assets Monitored

“After a few wins, the skepticism fell away and it became part of what we do.”

Gareth Taylor

CMC Steel

KCF's Superior Sensor Technology

Key Advantages of KCF’s Sensor Technology:

Minimal Measurement Error: KCF’s vibration sensors exhibit less than 6% error, compared to the 60–410% error range of competing sensors.

Patented Stability Design: KCF’s vibration sensors avoid the instability issues found in many wireless solutions, ensuring accurate diagnostics.

Proven Reliability at Scale: Unlike many predictive maintenance startups, KCF Technologies has a track record of successfully implementing scalable monitoring solutions across industries.

Sensor Overview

Metals Case Studies

Real-World Successes

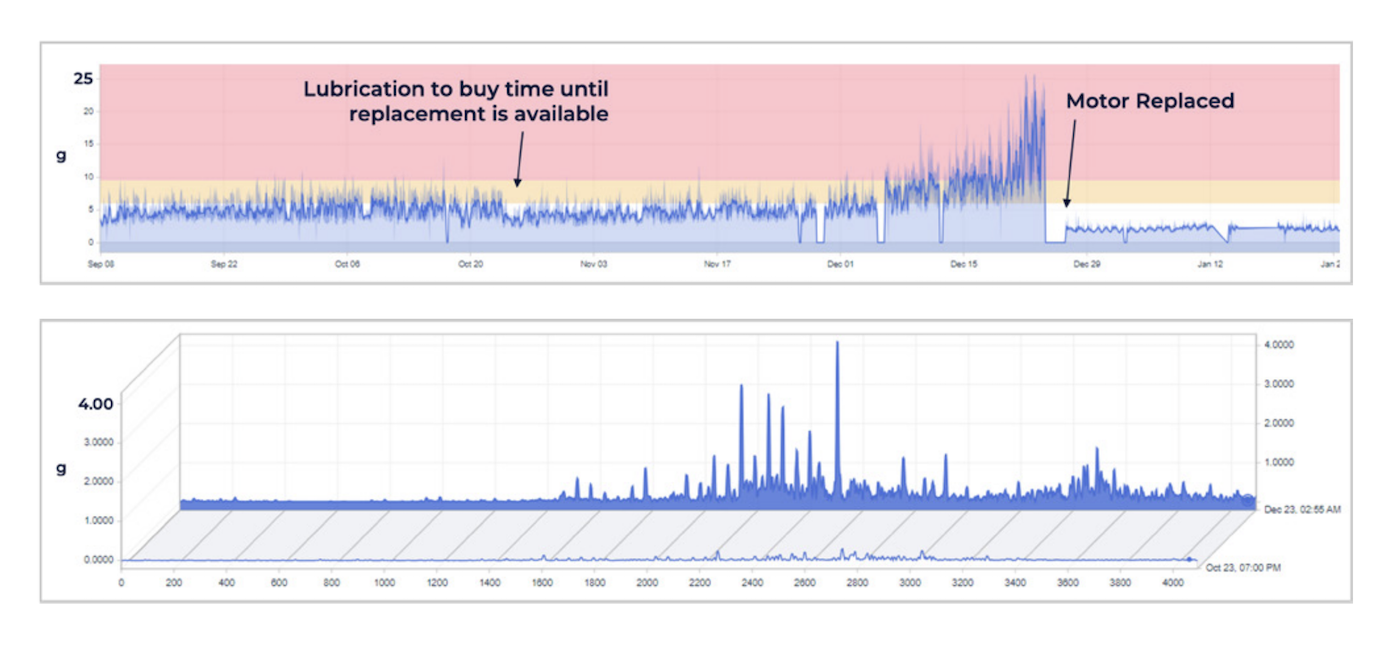

Baghouse Fan Motor

Vibration trends indicated a progressing bearing fault. Targeted lubrication extended asset life until a replacement could be installed. Post-repair data showed that vibration levels had returned to healthy baseline.

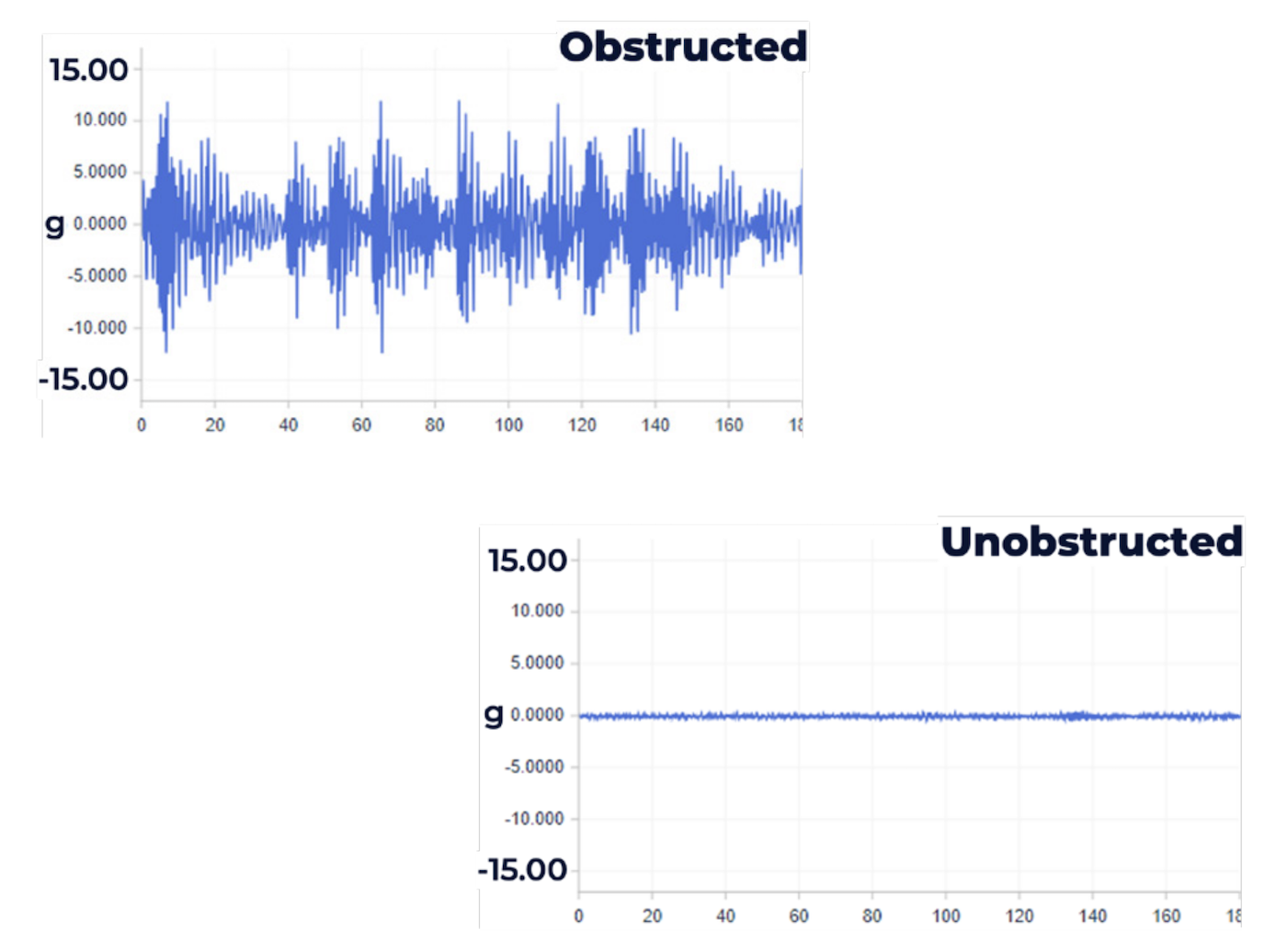

Pump Obstruction

A spike in vibration triggered an inspection. A large foreign object was found in the impeller, and it was removed before mechanical damage occurred.

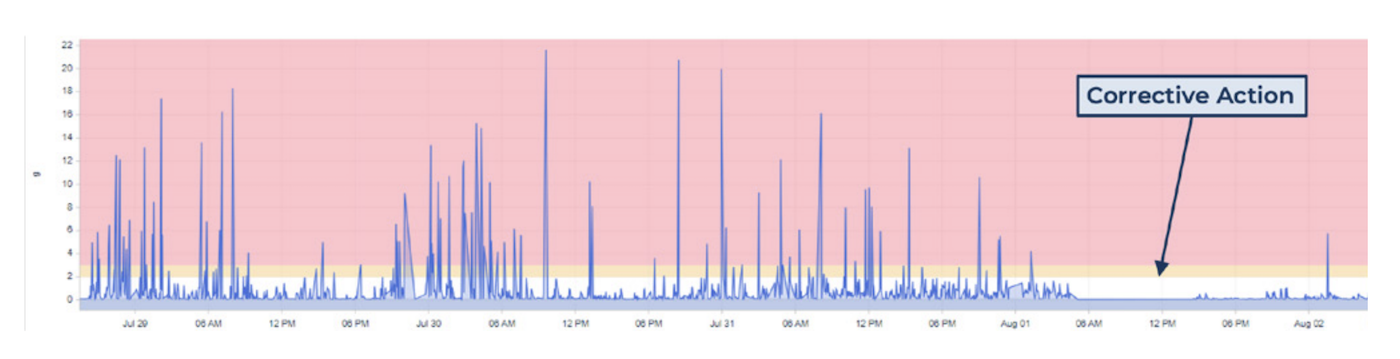

Crane

A failed cooling system threatened to overheat electrical drives. SMARTdiagnostics prompted emergency cooling, preventing a shutdown. Later analysis revealed mounting slop on the south bridge motor, which was repaired during a planned outage.

The Value of Predictive Maintenance

The metals industry faces a unique set of risks. Extreme loads, heat, and vibration levels make early fault detection essential. Predictive maintenance allows teams to move beyond time-based service and into condition-based action, focusing on what matters most. By combining real-time monitoring with expert review and root cause analysis, KCF Technologies helps sites:

- Detect developing faults before they result in failure

- Prioritize repairs based on actual machine health

- Prevent unplanned outages and reduce maintenance costs

Tools like SD Connect and Desk give teams the visibility and flexibility to act quickly without adding complexity to day-to-day operations.

Conclusion

Metal manufacturers don’t need more reports. They need a more straightforward way to identify what’s going wrong and fix it before it causes downtime. Predictive maintenance delivers that clarity. Across the metals industry, KCF customers are operating with fewer disruptions, stronger asset performance, and better planning. That’s the power of real-time machine health data, working where it matters most.

Learn how KCF’s machine health optimization platform will help you achieve peak plant performance at kcftech.com

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.