AI-Driven Predictive Maintenance for a Safer, Smarter Chemicals Industry

How Predictive Maintenance Drives Safer, More Reliable Operations

Introduction

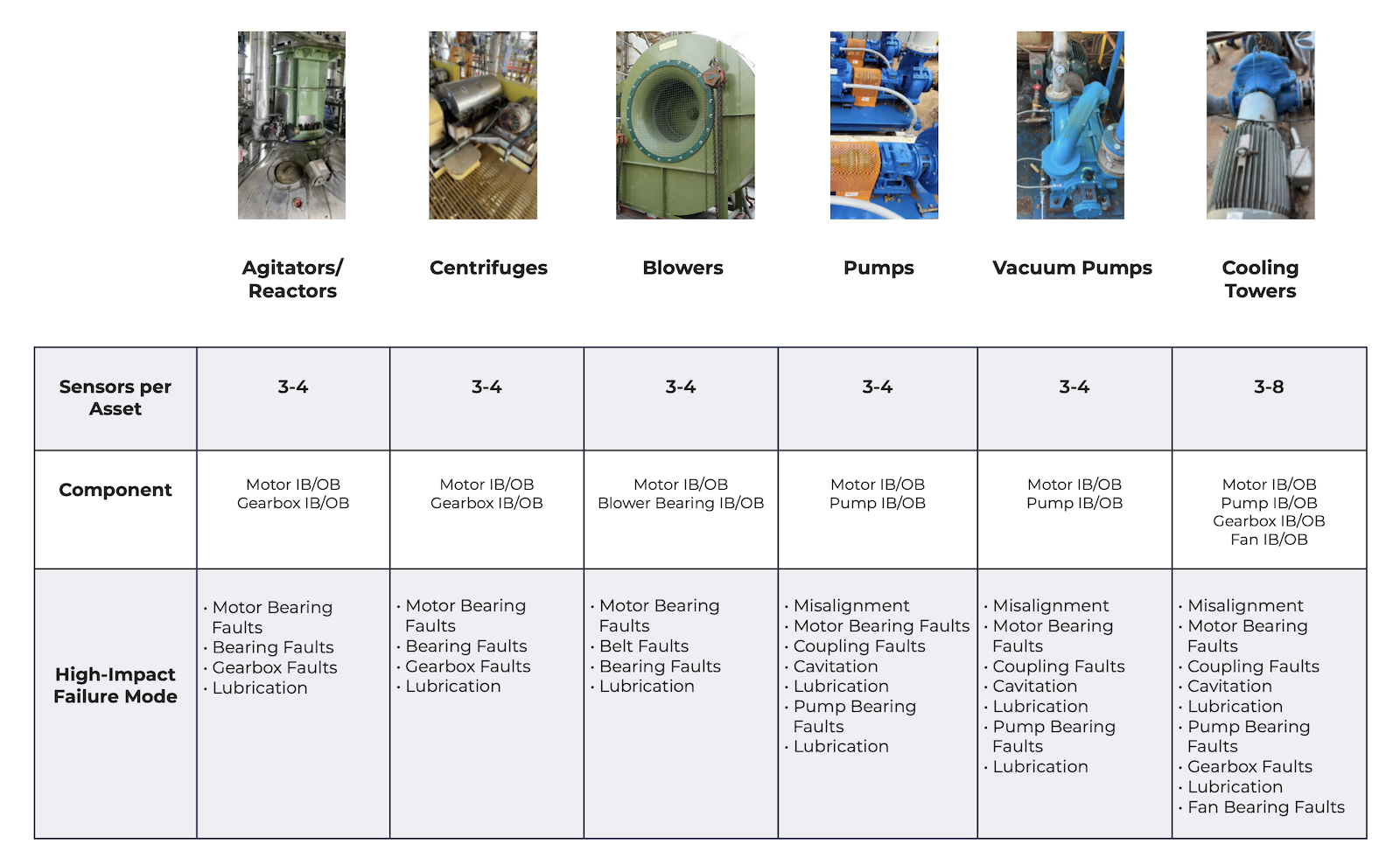

In the chemical industry, equipment reliability isn’t just about performance; it’s about safety, environmental risks, and uninterrupted production. Pumps, blowers, reactors, and other plant equipment operate under high stress, and even minor mechanical issues can escalate into costly events.

Yet despite routine preventive maintenance, faults like lubrication breakdowns, bearing defects, and alignment issues often go undetected until it’s too late. Predictive maintenance fills that gap, giving teams the tools to catch problems early, act decisively, and accurately to avoid unplanned downtime.

Industry-wide Results

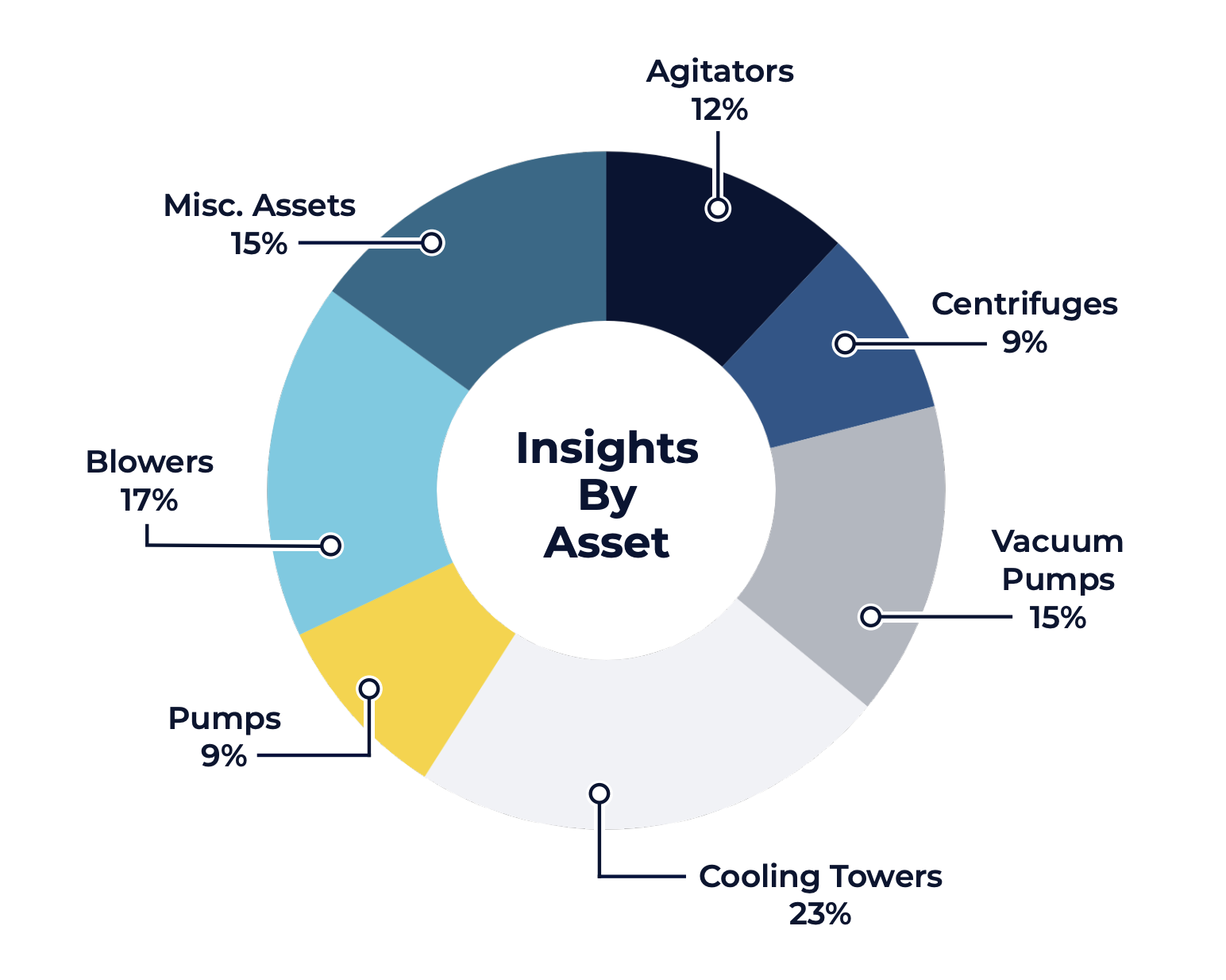

KCF Technologies has worked with over 40* chemical production sites to improve reliability through our Comprehensive Machine Health Platform.

*all figures as of 2025

The outcomes are significant:

3,349+

Assets Monitored

3,329

Hours of Downtime Avoided

19.2M

Documented Savings

Assets Monitored

“If data and insights are to create any value, they must influence people and systems’ behaviors. That’s why culture transformation is part of the key.”

Prabhu Ramachandran

Kaneka

KCF's Superior Sensor Technology

Wireless vibration sensors are a crucial enabler of predictive maintenance, but not all sensors are created equal. Many solutions on the market suffer from poor design, resulting in false positives, missed diagnoses, and erosion of trust in condition monitoring programs. KCF Technologies has set the industry standard with its patented Version 3 High-Definition sensor, engineered for unparalleled accuracy and reliability.

Key Advantages of KCF’s Sensor Technology:

Minimal Measurement Error: KCF’s sensors exhibit less than 6% error, compared to the 60-410% error range of competing sensors. Patented Stability

Design: KCF’s vibration sensors avoid the instability issues found in many wireless solutions, ensuring accurate diagnostics.

Proven Reliability at Scale: Unlike many predictive maintenance startups, KCF Technologies has a track record of successfully implementing scalable monitoring solutions across industries.

Sensor Overview

KCF’s High-Definition Vibration Sensor offers industry-leading data acquisition—collecting the full spectrum of data as often as once every minute. Our unique ability to take high-interval, full-spectrum data allows for a best-in-class machine learning training dataset, delivering exceptional predictive maintenance analytics.

Chemicals Case Studies

Real-World Successes

1

Case Study

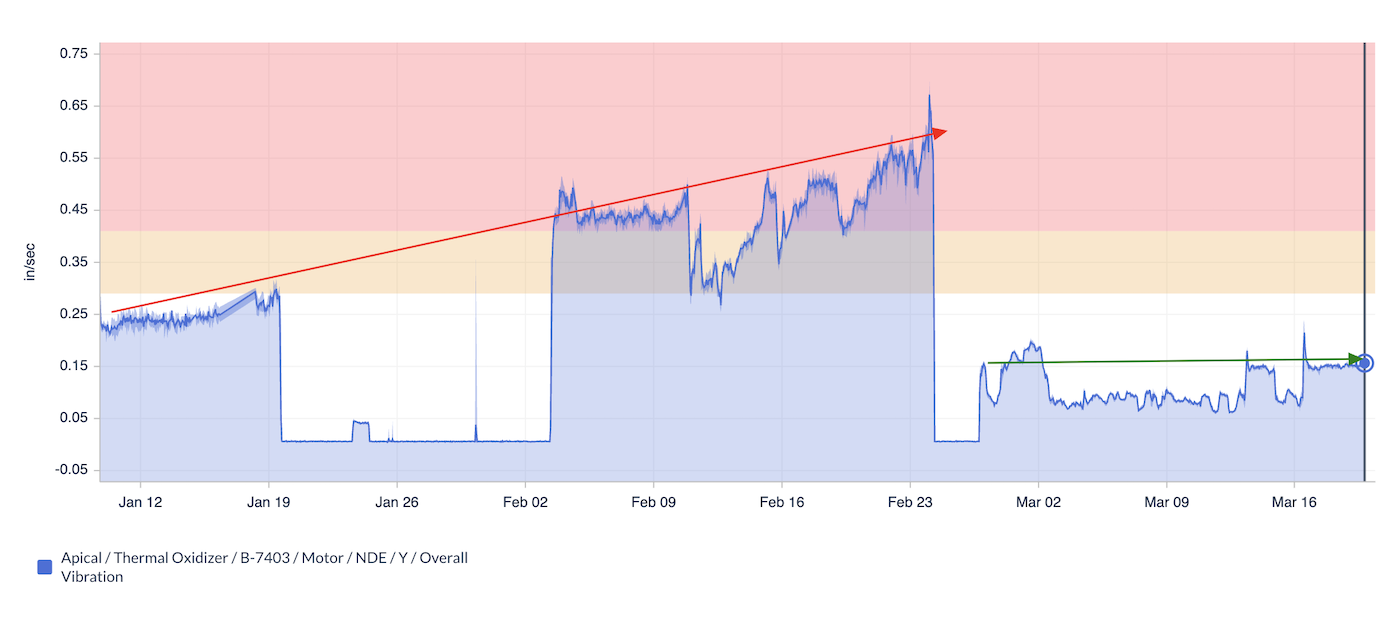

Thermal Oxidizer Fan

SMARTdiagnostics identified rising vibration on both the motor and the fan. Historical context from a previous fault helped an analyst recommend Babbit inspection. The customer confirmed looseness, replaced worn parts, and added a grounding ring.

DOWNTIME AVOIDED 12 hours

ESTIMATED SAVINGS $14,000

2

Case Study

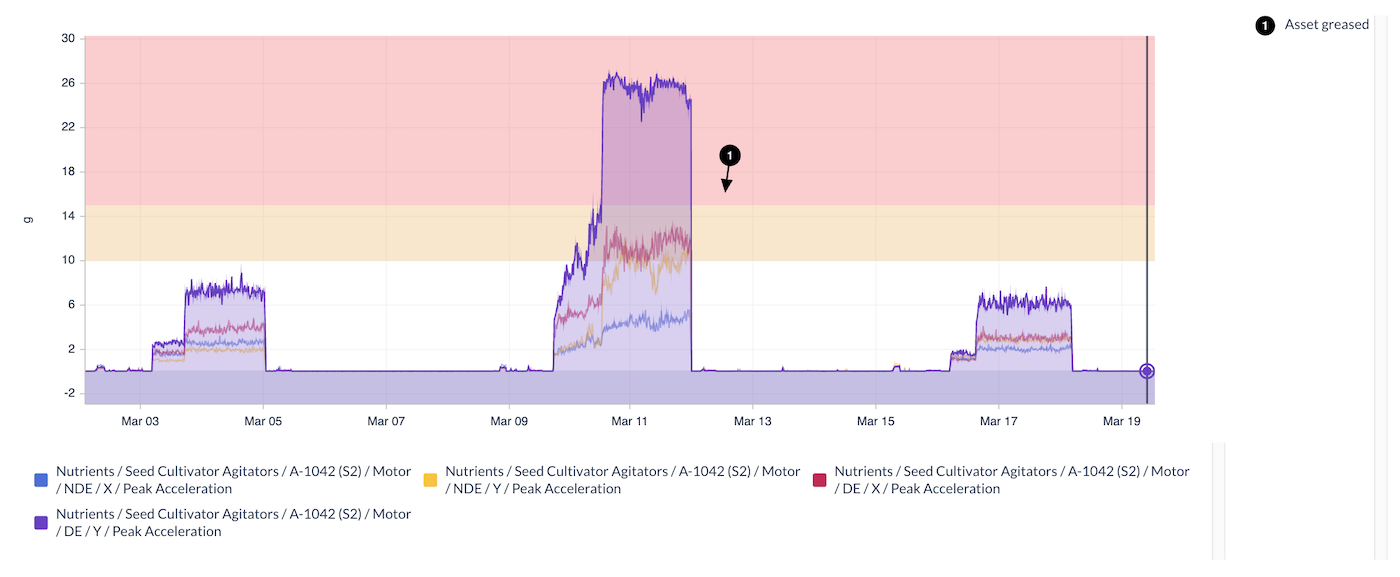

Agitator

Initial lubrication reduced vibration temporarily, but levels rose again. A deeper inspection revealed worn bearings and a dropped blade assembly. The team replaced the motor, gearbox, and blades.

DOWNTIME AVOIDED 4 hours

ESTIMATED SAVINGS $28,000

3

Case Study

RTO Oxidizer Fan

Data indicated developing misalignment and structural looseness. The customer scheduled alignment and cleaning during the next outage.

DOWNTIME AVOIDED 8 hours

ESTIMATED SAVINGS $8,000

4

Case Study

Chiller Pump

SMARTdiagnostics detected multiple developing faults. Greasing the bearings restored vibration levels, avoiding failure. The team is now planning further steps to protect the asset from contamination.

ESTIMATED PART COST AVOIDED $270

partner impact

SABIC x KCF Technologies

Following a sock filter change on an extruder motor, SMARTdiagnostics detected increased bearing stress. Early alerts helped SABIC pinpoint the filter issue as the root cause before failure occurred.

Downtime Avoided: 8 hours

Estimated Savings: $107,000

partner impact

BASF x KCF Technologies

Rising vibration on a feed pump revealed underlying base damage. The issue was addressed during a planned outage—avoiding downtime across four reactor trains.

Downtime Avoided: 8 hours

Estimated Savings: $86,000

Why Choose KCF Technologies?

KCF Technologies combines powerful sensor technology, expert engineering support, and real-time data analytics to deliver unparalleled predictive maintenance results.

Choosing KCF means gaining:

- Earlier Fault Detection: Catch lubrication breakdowns, misalignment, and bearing issues before they escalate.

- Major Cost Savings: Prevent costly unplanned shutdowns and equipment damage.

- Enhanced Safety & Compliance: Identify risks before they create hazards for workers or the environment.

- Reliable, Actionable Data: Leverage industry-leading sensor precision for informed decision-making.

- Optimized Equipment Lifespan: Extend the health of pumps, reactors, blowers, and other critical assets.

Conclusion

In the chemical industry, reliability is about more than performance; it’s about safety, environmental protection, and uninterrupted production. KCF Technologies empowers chemical plants to minimize risks, avoid downtime, and maximize efficiency. With SMARTdiagnostics®, operations can shift from reactive to proactive maintenance, securing a stronger, safer, and more competitive future.

Learn how KCF’s machine health optimization platform will help you achieve peak plant performance at kcftech.com

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.