Revolutionizing Predictive Maintenance in the Automotive Industry

How Predictive Maintenance Drives Safer, More Reliable Operations

Cranes Lifts Paint Fans

Introduction

Automotive manufacturing drives innovation across the global economy, producing the vehicles that keep the world moving. Yet the fast-paced, high-volume environments of automotive plants present constant challenges to maintaining uptime. Unexpected equipment failures can lead to costly downtime, production delays, quality issues, and safety risks.

KCF Technologies is transforming automotive maintenance with SMARTdiagnostics®, a predictive maintenance platform that combines real-time machine health monitoring with expert-driven analytics. By empowering automotive manufacturers to detect developing faults early, KCF helps prevent failures before they occur, enhancing quality, reducing downtime, and optimizing production efficiency.

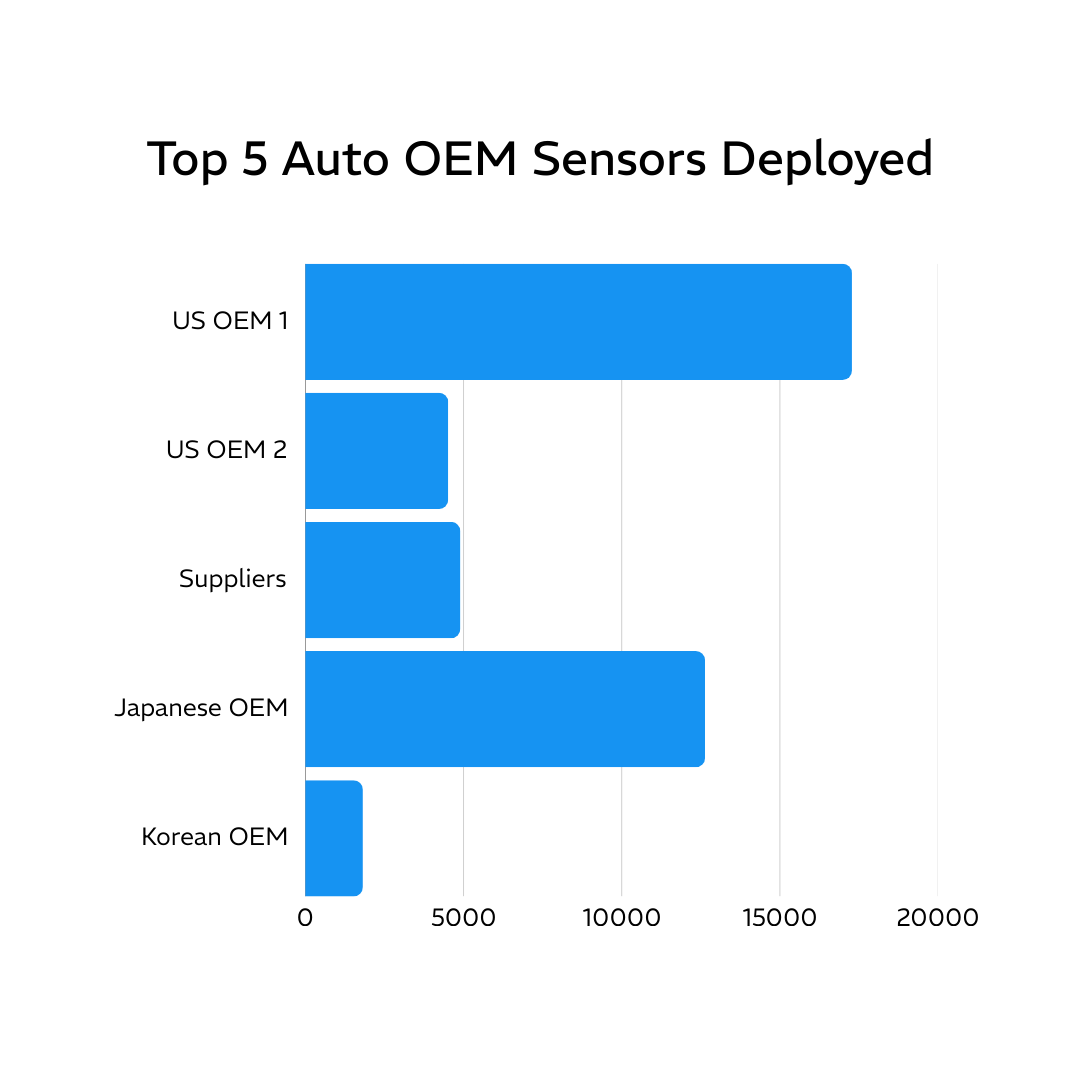

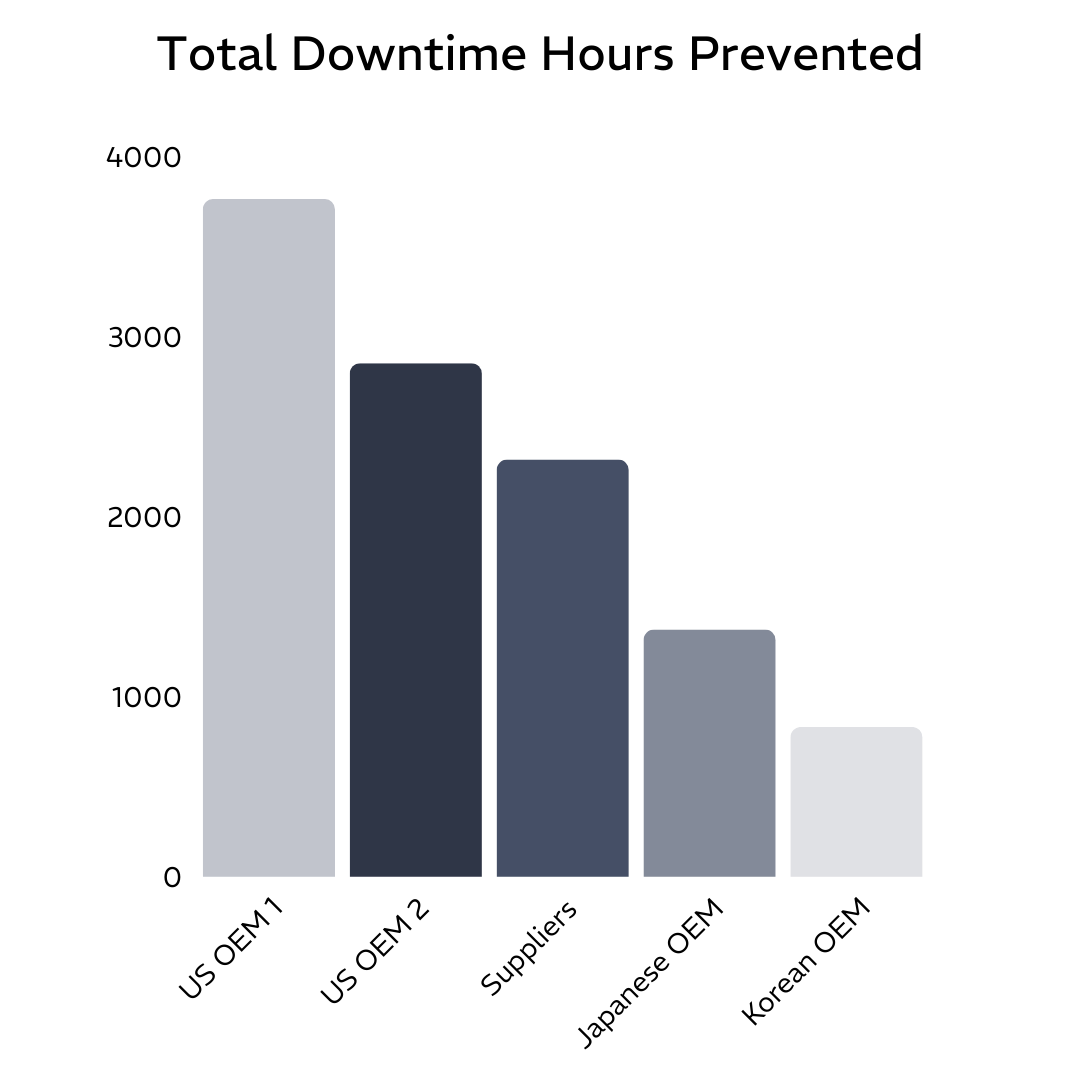

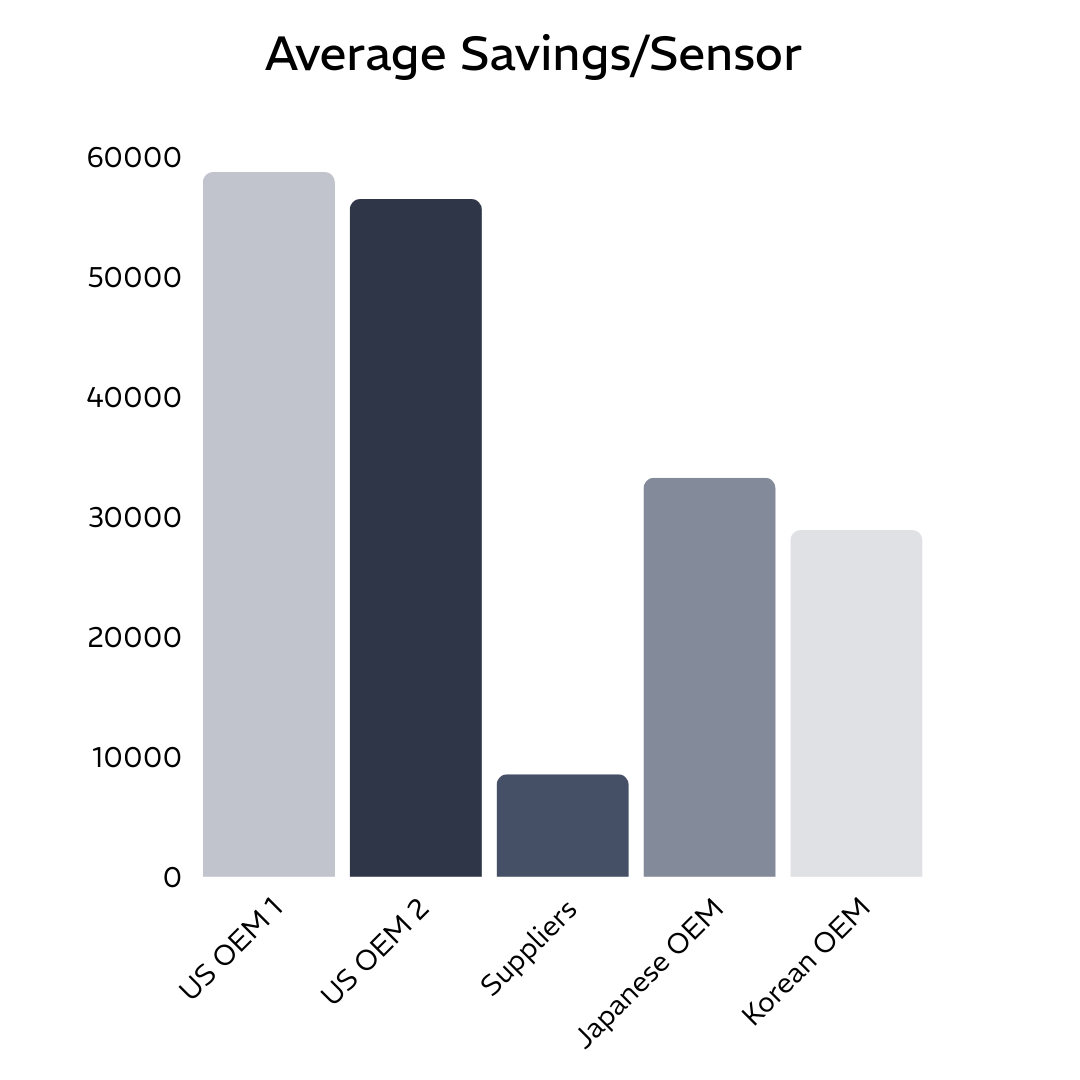

Industry-wide Results

KCF Technologies has partnered with more than 1,000 manufacturing locations.

*all figures as of 2025

*all figures as of 2025

Average Annual ROI

US OEM 1

14.34x

ROI

US OEM 2

8.78x

ROI

US OEM 3

15.79x

ROI

Japanese OEM

11.3x

ROI

Korean OEM

7.12x

ROI

Global Footprint

- 11 Years

- 64 Plants

- 27k Assets

- 6 Major Auto Manufacturing Partners

- 12 Suppliers

- Auto, Metals, Agriculture, Heavy Equipment, Aerospace

Assets Monitored

“We started small, and we are scaling as we go and, as we are integrating more sensors and taking advantage of machine learning, it will provide us deeper insights into our processes, making process changes.”

Yahya Khan

Clarios

KCF's Superior Sensor Technology

Wireless vibration sensors are a crucial enabler of predictive maintenance, but not all sensors are created equal. Many solutions on the market suffer from poor design, resulting in false positives, missed diagnoses, and erosion of trust in condition monitoring programs. KCF Technologies has set the industry standard with its patented High-Definition vibration sensor, engineered for unparalleled accuracy and reliability.

Key Advantages of KCF’s Sensor Technology:

Minimal Measurement Error: KCF’s vibration sensors exhibit less than 6% error, compared to the 60–410% error range of competing sensors.

Patented Stability Design: KCF’s vibration sensors avoid the instability issues found in many wireless solutions, ensuring accurate diagnostics.

Proven Reliability at Scale: Unlike many predictive maintenance startups, KCF Technologies has a track record of successfully implementing scalable monitoring solutions across industries.

Sensor Overview

KCF’s High-Definition Vibration Sensor offers industry leading data acquisition, collecting the full spectrum of data as often as once every minute. Our unique ability to take high-interval, full spectrum data allows for a best-in-class machine learning training dataset, delivering exceptional predictive maintenance analytics.

Automotive Case Studies

Real-World Successes

1

Case Study

Lifts

At an automotive assembly plant, KCF’s IoT HUB captured vibration data only during lift operation, eliminating idle noise and revealing a bearing fault early. SMARTdiagnostics flagged the issue, prompting a quick replacement that prevented a breakdown, avoided two hours of downtime, and saved $1.8 million in production losses.

IN SAVINGS $1,800,500

DOWNTIME SAVED 2 Hours

2

Case Study

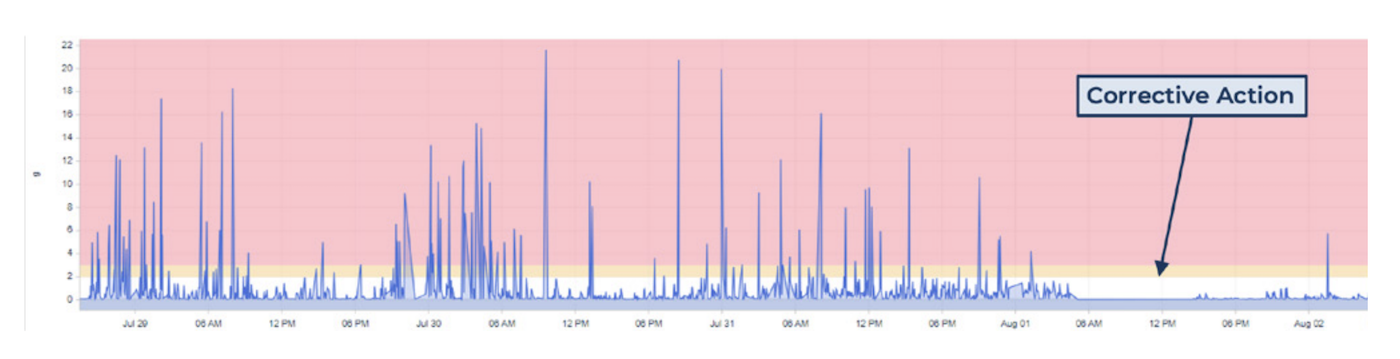

Paint Fans

SMARTdiagnostics detected rising vibration on an automotive paint shop exhaust fan, prompting inspection and lubrication. When levels spiked again, SENTRYsolutions advised immediate repair. Damaged bearings were replaced before failure, preventing four hours of unplanned downtime and maintaining product quality.

DOWNTIME SAVED 4 Hours

3

Case Study

Cranes

A failed cooling system threatened to overheat electrical drives. SMARTdiagnostics prompted emergency cooling, preventing a shutdown. Later analysis revealed mounting slop on the south bridge motor, which was repaired during a planned outage.

DOWNTIME AVOIDED 32 Hours

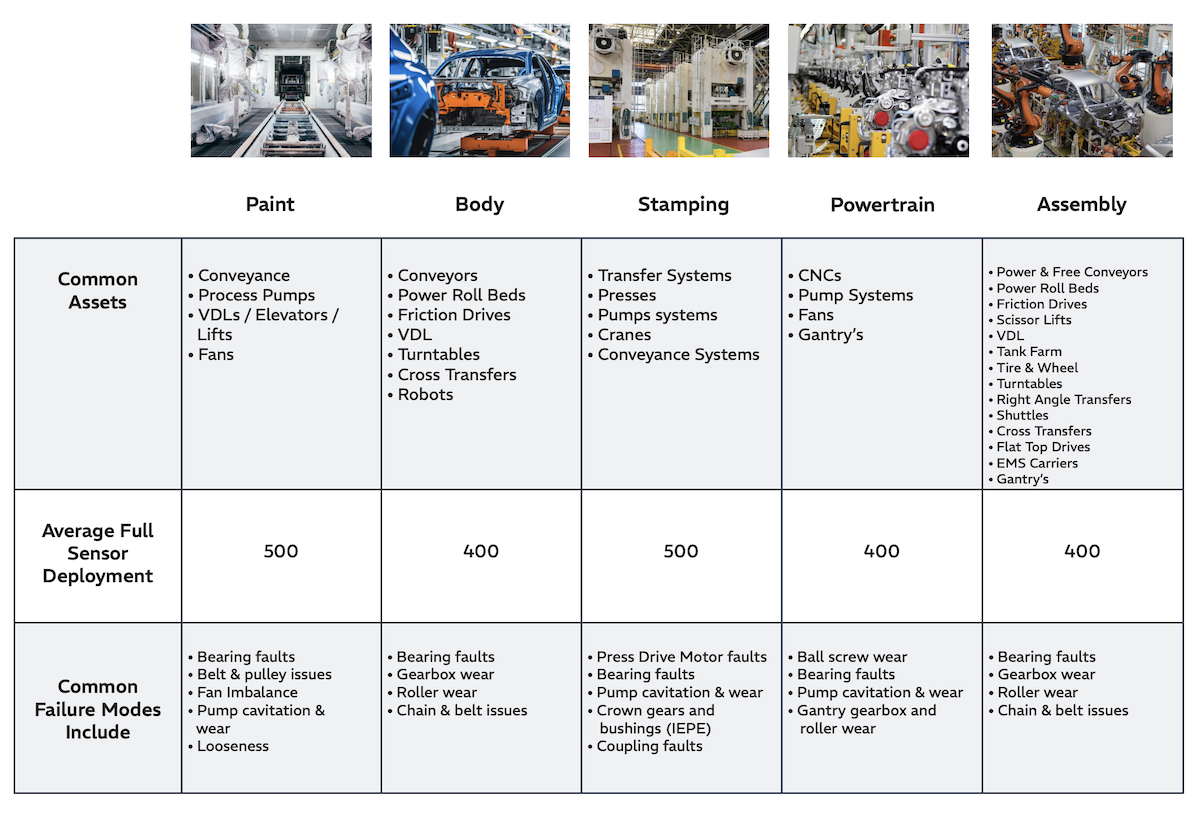

The Value of Predictive Maintenance

The automotive industry operates at unmatched speed and precision—every line, lift, and conveyor plays a critical role in keeping production moving. Extreme operating conditions, intermittent cycles, and high throughput make early fault detection essential. Predictive maintenance allows teams to move beyond time-based service and into condition-based action, focusing on what matters most.

By combining real-time monitoring with expert review and root cause analysis, KCF Technologies helps automotive manufacturers:

- Detect developing faults before they cause downtime

- Prioritize maintenance based on actual machine health

- Prevent unplanned outages and reduce maintenance costs

Tools like SD Connect and Desk give maintenance and reliability teams the visibility and flexibility to act quickly without adding complexity to daily operations.

Conclusion

Automotive manufacturers don’t need more data—they need clear, actionable insights to keep production on schedule. Predictive maintenance delivers that clarity. Across paint shops, stamping lines, and final assembly, KCF customers are operating with fewer disruptions, stronger asset performance, and smarter planning. That’s the power of real-time machine health data, working where it matters most.

Learn how KCF’s machine health optimization platform helps automotive plants achieve peak performance at kcftech.com.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.