40 HP Aeration Blower (Blower 8)

Fault Type: Bearing Fault

In a Municipal Utility District, the diligent monitoring of equipment led to the early detection of an impending failure in their 40 HP Aeration Blower, labeled as Blower 8. The blower began to show alarming signs when KCF Technologies SMARTdiagnostics software detected an unusually high overall vibration. This elevated vibration was particularly driven by a spike in its run speed, often a harbinger of severe machinery imbalance or even structural issues.

Example 1

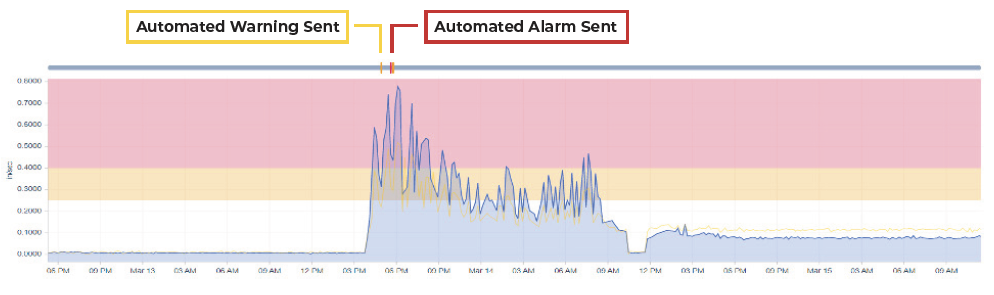

On the night of May 13th, at 10:48 PM CST, the monitoring system couldn’t ignore the anomaly anymore. An automated alert was dispatched, sounding the alarms about the potential issue. Two days later, on May 15th at 9:44 AM CST, KCF Technologies decided it was time to escalate the matter. They weren’t merely concerned about the persistent high vibrations; they feared the consequences of ignoring such signs.

Their concerns were validated upon inspection. Hidden within the depths of the Blower, a bearing, essential for smooth operations, was discovered to be cracked. It was a ticking time bomb. If not for the timely detection, the blower might have suffered severe collateral damage, leading to a potential shutdown and hefty repair costs.

Thankfully, the cracked bearing was swiftly replaced. The blower’s vibrations returned to their healthy baseline, and a potential catastrophe was averted. It was a testament to the importance of 24/7 monitoring and the swift actions that follow the detection of anomalies.

75 HP Aeration Blower (Blower 2)

Fault Type: Coupling

In another Municipal Utility District, an urgent alarm was brought to the attention of the maintenance team. Blower 2 of the 75 HP Aeration system, a critical component of the district’s infrastructure, was exhibiting troubling signs. The monitoring system, SMARTdiagnostics, developed by KCF Technologies, had picked up on these anomalies.

Example 2

The primary concern? A fault in the coupling. Vibrations had been steadily increasing, and it wasn’t long before they soared past acceptable levels. But it wasn’t just the overarching tremors that had technicians worried. A particularly intense 3x vibration spike hinted at a more intricate problem, suggesting a potential misalignment or defect in the coupling.

Prompt action was essential. Before any catastrophic failures could ensue, the district’s engineers made the call: shut down the asset and address the issue at its root. And that’s precisely what they did, opting to replace the coupling altogether, ensuring the longevity of the equipment.

On the evening of March 13, 2023, an automated notification from SMARTdiagnostics confirmed what the team already knew. At 6:35:49 PM Eastern Standard Time, the blower’s vibrations had set off the alarm. Ensuring transparency and swift action, an email and text message was sent out, detailing the event and providing avenues for acknowledgment.

40 HP Aeration Blower (Blower 6)

Fault Type: Coupling / Misalignment

At a local Municipal Utility District, Blower 6 of the 40 HP Aeration system began showing troubling signs. As overseen by KCF Technologies SMARTdiagnostics Software, a spike in its usual humming was detected, indicating an anomaly in its smooth operations.

Example 3

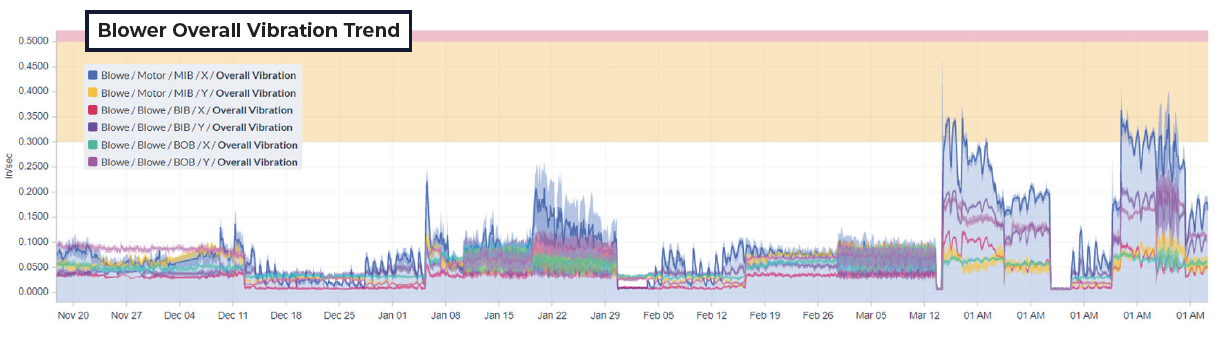

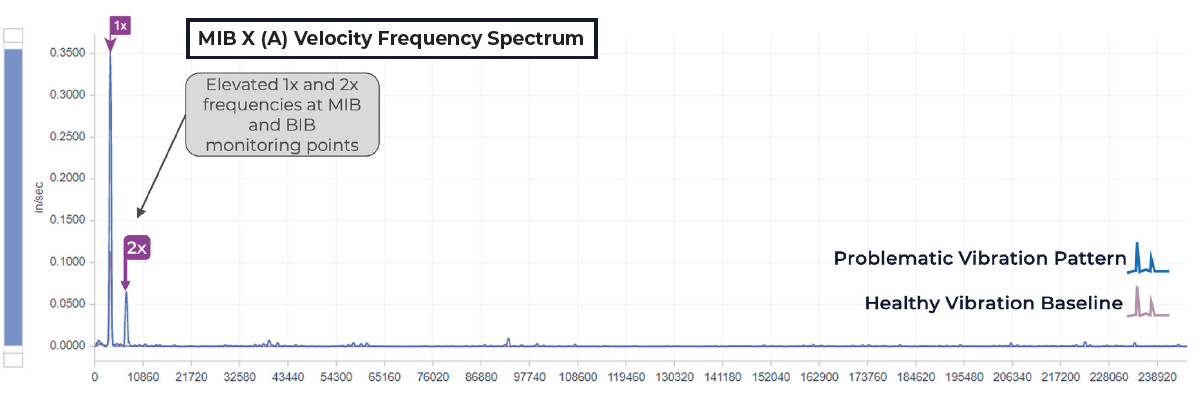

Two Significant Issues Came to Light: Problems with the coupling and potential misalignment. The former was evidenced by an overall increase in vibrations when compared to the blower’s typical baseline, prompting an automated warning to be dispatched. The latter, misalignment, was suggested by heightened 1x and 2x frequencies, particularly noticeable at the Motor IB and Blower IB monitoring points, known hotspots for such discrepancies.

Knowing the ramifications of unchecked vibrations, the district’s engineers took immediate action. On inspecting the asset, the faulty coupling was evident. Recognizing the potential risks of prolonged operation with such an issue, a decision was made. They scheduled the blower for an overhaul during the next available downtime, intent on replacing the damaged coupling. This preventive measure would not only save time in potential repairs but also negate the need for an unscheduled maintenance session, should the coupling have failed entirely.

The blower’s vibration trends, spanning several months, painted a clear picture: while there were occasional fluctuations in its vibrations, the recent anomalies were unmistakable. It was a stark reminder of the importance of constant vigilance and the role of timely interventions in preserving vital municipal assets.

Water Treatment Well Pump

Fault Type: General—Process, Looseness, Mechanical Seal Fault

In one Municipal Utility District, the Water Treatment Well Pump was under keen observation by KCF Technologies Machine Health Platform. Distinct anomalies were noted in the pump’s operations, even though a concrete fault type remained unconfirmed.

Example 4

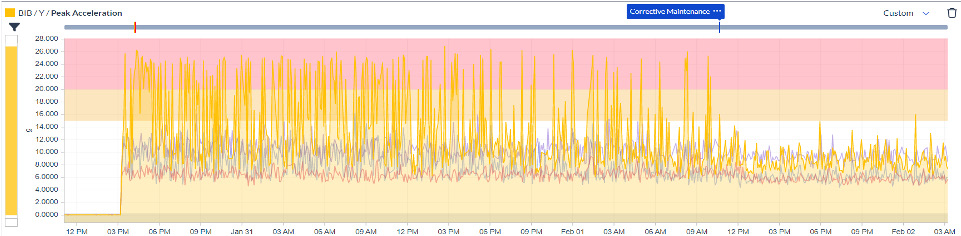

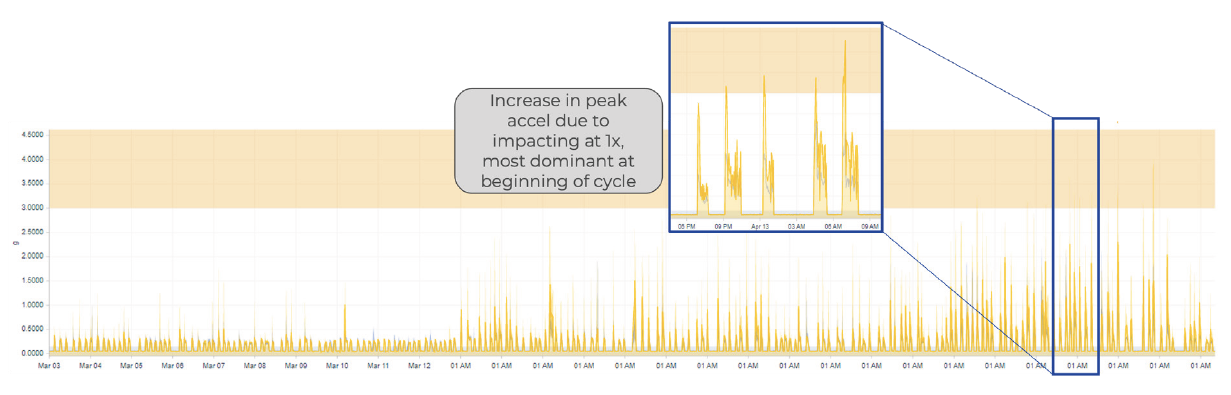

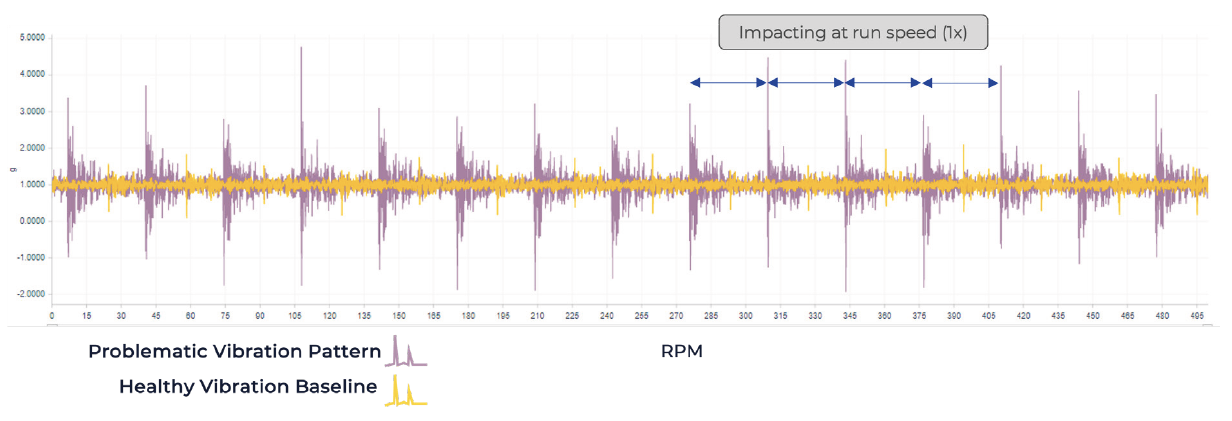

Diving deeper into the metrics, it was observed that the most significant impact of this irregularity was at the start of the operating cycle. The Pump Peak Acceleration Trend showcased these heightened peaks, mainly at the 1x run speed, which was especially pronounced at the cycle’s onset.

The most telling sign was the sharp rise in peak acceleration, particularly evident when the pump ran at its typical speed. This sudden jolt might imply several things: the aforementioned mechanical looseness, variations in the flow rate, or the potential mechanical seal fault.

However, before jumping to conclusions, it was paramount to compare this problematic vibration pattern with the known healthy vibration baseline of the pump. The contrast was evident: the fluctuations seen in the recent data were not characteristic of the pump’s standard behavior.

3 potential concerns

- General process issue

- Potential looseness in the mechanical components

- Suspicions of a mechanical seal fault

It’s clear that such anomalies warrant immediate intervention to ensure the continued efficiency and safety of the Water Treatment Well Pump.

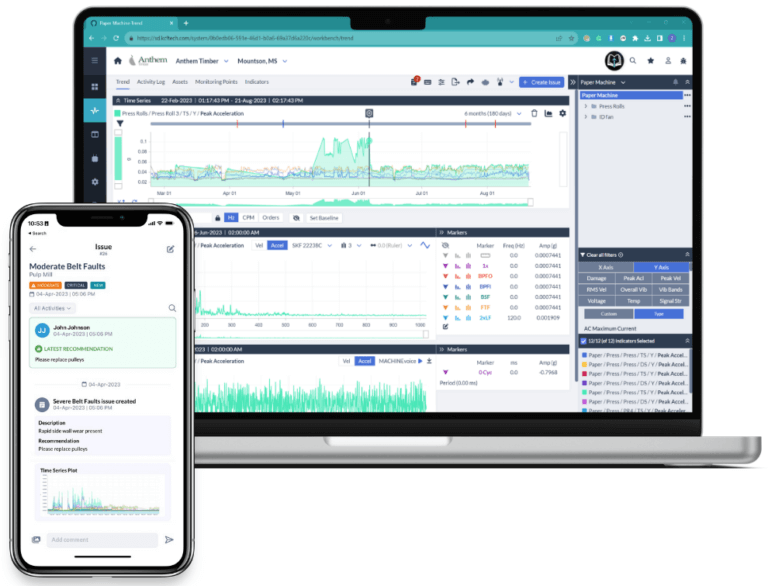

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.