Nabors: Reduced Downtime and Saved $320K With AI-Based Predictive Maintenance

Case Study

Mud Pumps

Use machine health offering from RigCLOUD® and KCF Technologies (“KCF”) to proactively predict equipment maintenance on drilling rigs, minimize equipment damage and avoid downtime.

OBJECTIVE

Trial Overview

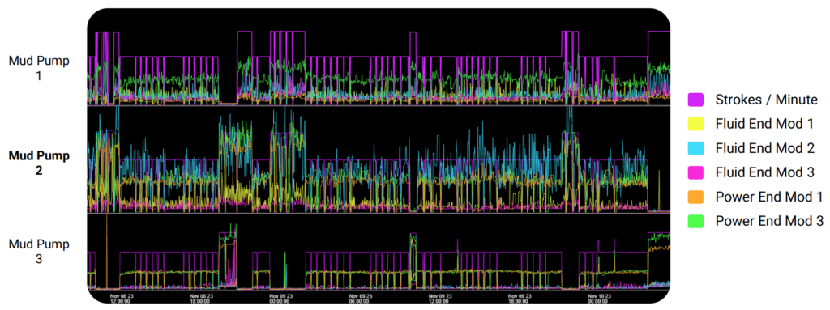

Sensors were installed to monitor mud pump vibrations. Artificial Intelligence (AI) and certified subject matter experts from the Rigline 24/7 center in Houston remotely analyzed the data to identify potential issues. Recommended actions were communicated to the rig manager. Feedback was incorporated back into the system for continuous improvement.

4 rigs in South & West Texas

96 sensors

12 mud pumps

5 months

Results

Nabors avoided $320,000 in equipment costs, and downtime, during the pilot.

Highlights: Mitigating Power End Failures

KCF sensors detected abnormal power end vibrations from a mud pump. Upon inspection, the external oiler was not discharging oil over the power end or crossheads. Proactive adjustments were made, avoiding a potential failure with an estimated cost of $160,000 plus downtime.

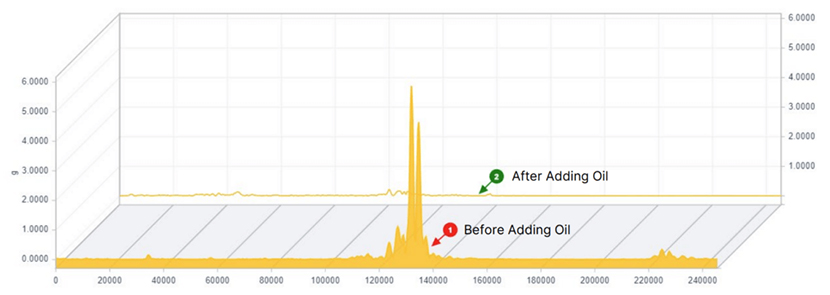

KCF sensors detected high vibrations on a mud pump, upon inspection, the lube oil level was low. The crew promptly added oil, improving lubrication and lowering the vibrations. The proactive maintenance avoided a potential power end failure, resulting in a cost avoidance of $160,000.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.