1

Case Study

When predictive diagnostics meet expert analysis, even the most subtle warning signs can prevent major disruptions. In this case, SMARTdiagnostics DeskAI machine learning model flagged an anomaly in the exhaust system’s fan shaft, prompting a deeper investigation. What followed was a collaborative effort between data and vibration expertise that uncovered a hidden mechanical failure before it could trigger costly unplanned downtime. Here’s how the team turned insight into action, saving time, money, and operational confidence.

DETECTION: SMARTdiagnostics detected sudden peak acceleration spikes on the Exhaust Fan Shaft, pointing to a possible bearing fault.

ACTION: An analyst advised checking operating patterns and lubrication, but inspection revealed a failed retainer ring that caused the bearing to seize. The repair was completed during scheduled downtime.

IMPACT: Proactive detection and repair avoided four hours of unplanned downtime and delivered more than $450,000 in savings.

Identifying a Machine Failure in the Making

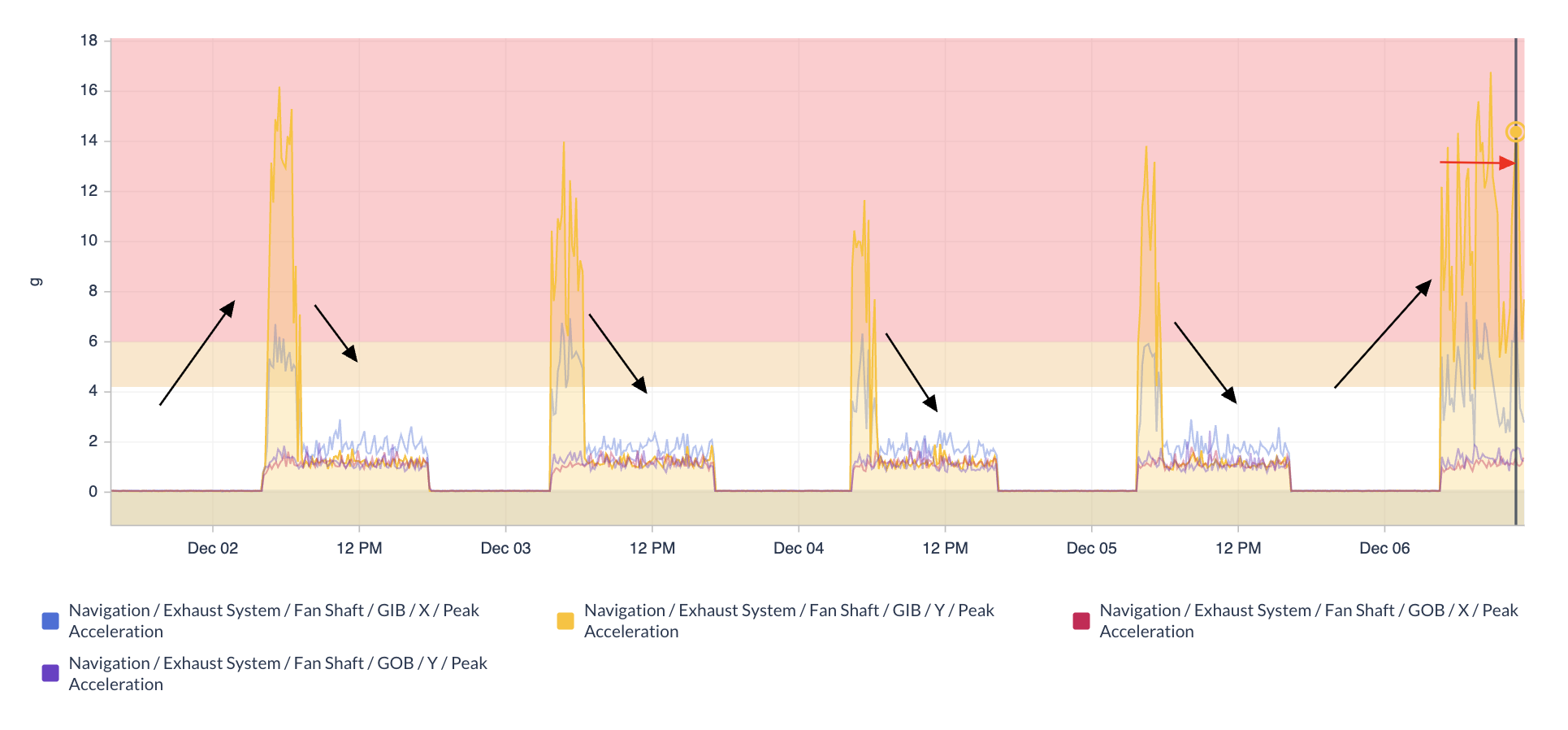

SMARTdiagnostics called out an increase in peak acceleration on the Fan Shaft of this Exhaust System, indicating a possible bearing fault. Viewing the time series plot, clear sudden spikes and then decreases shortly after, indicating a potential process driven failure.

Using this data, a SENTRYsolutions analyst recommended looking into if the fan was being started or ran differently on that day versus others and recommended inspecting the bearing for lubrication, to rule out more common causes. When the customer reported that the bearing was greased regularly, it was clear something deeper was occurring.

Upon inspection, despite regular greasing, a retainer ring had failed, causing the bearing to seize. With this knowledge in hand, the team was able to perform a repair at the next scheduled downtime. Proactive action prevented four hours of unplanned downtime, resulting in more than $450,000 in savings.

$450,000

in Customer Savings

4 Hours

of Downtime Saved

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.