The Challenge

A non-Nabors drilling rig in Latin America faced critical risks due to undetected top drive equipment failures. The top drive blower motor was in poor condition, and the lubrication system was malfunctioning, increasing the risk of overheating, equipment failure, and potential fires.

Top Drive Coverage:

- Bearing Faults

- Rotor Bar Faults

- Stator Windings

- Overheating

- Imbalance

- Looseness

- Misalignment

- Cracked Gear Teeth

- Gear Wear

- Gear Backlash

- Gear Misalignment

- Gear Loose Fit

- Gear Assembly Phase Problems

The Solution

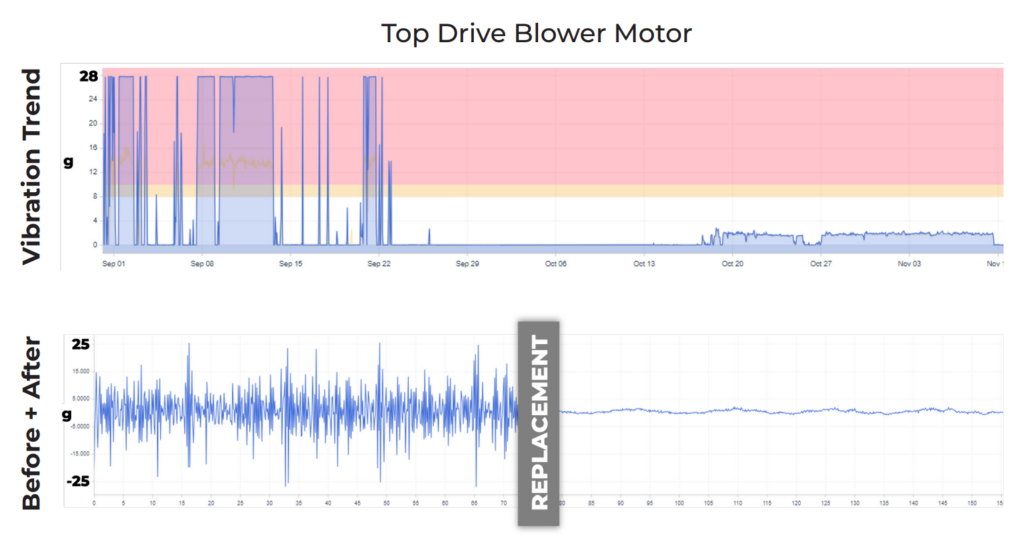

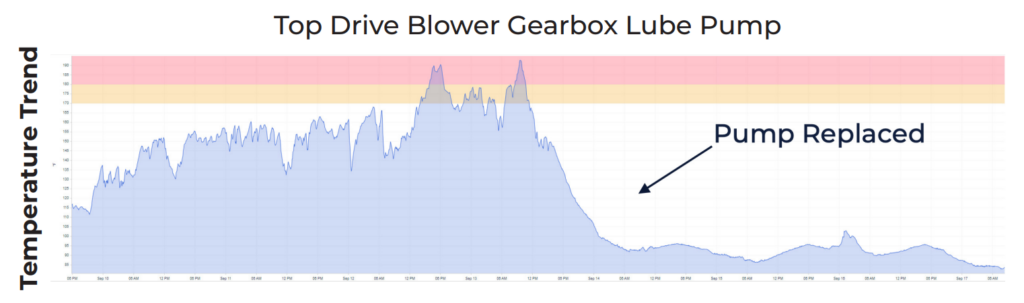

By deploying KCF SMARTdiagnostics through RigCLOUD®, real-time vibration and temperature monitoring provided early warnings of equipment issues:

- The blower motor was identified as critical, preventing a potential shutdown and costly top drive replacement.

- A lube pump failure led to dangerously high oil temperatures. After replacing the pump, operating temperatures dropped by 70°F, preventing further damage and reducing fire risk.

The implementation resulted in $140,000 avoided in downtime and equipment failure across three days, reduced downtime and improved operational efficiency, and extended asset life with AI-driven predictive maintenance.

Conclusion

By integrating predictive monitoring with KCF SMARTdiagnosticsand RigCLOUD®, drilling rigs can proactively detect failures, reduce costs, and enhance safety, maximizing their uptime and operational performance.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.