Transforming Culture in the Digital Business Landscape

In today’s fast-changing manufacturing world, adopting digital transformation has become a vital strategy for companies striving to stay competitive. Beyond the buzz of technology and data-driven solutions, a crucial yet often overlooked aspect is the significant role that cultural change plays. Prabhu Ramachandran, a visionary leader and member of Kaneka’s Digital Transformation (DX) team, is at the forefront of driving this essential shift in the IIoT production and manufacturing space.

The Journey Begins with KCF Technologies

Kaneka, a global chemical manufacturer, started its journey with KCF Technologies in early 2021, when Prabhu embarked on having an impactful partnership with KCF. Right from the start, both Prabhu and KCF Technologies acknowledged the pivotal role of thoughtful planning as a steppingstone for any successful digital transformation.

It was during the 2022 Manufacturing the Future Summit, hosted by KCF, that Prabhu illuminated the path for which Kaneka finds successes and how other companies can navigate their own digital transformation journeys. starting with his guiding vision:

Think Big. Start Small. Scale Fast.

This guiding vision for businesses starting their transformation journey focuses on concrete outcomes, closely aligned with core business goals, showcasing the central role of creating value in every facet of the transformation process.

Working together on this journey with Prabhu, three key takeaways have been recognized as the essence of Kaneka’s transformation:

1

Operational Agility

Adaptability and flexibility in business processes to respond to changing market dynamics.

2

Workforce Enablement

Empowering employees with the necessary skills and tools to drive transformation.

3

Digital Technology Integration

Seamlessly integrating technology across all aspects of the business.

Digital Transformation = Engineering and Technology Specifications + People Transformation

This equation underscores the relationship between technological strides and the cultural change led by individuals. The true power of digital transformation is not just in technology but in the collective force of people driving change.

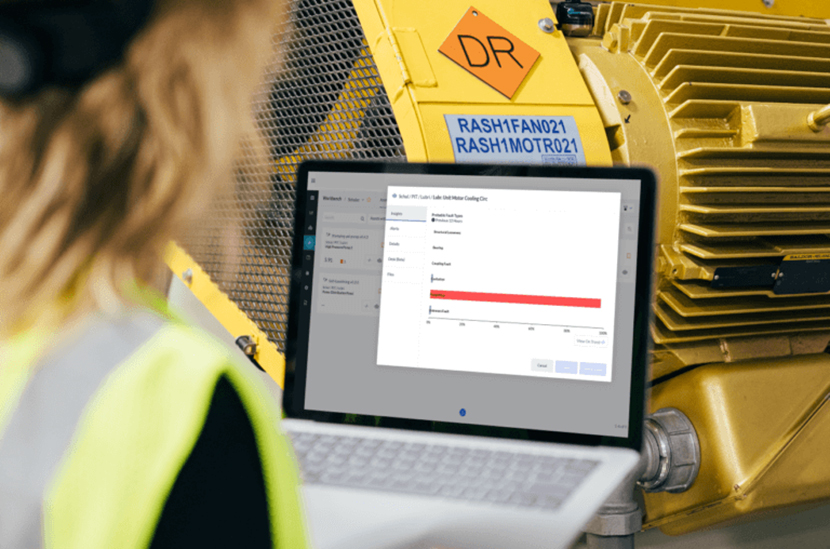

Early in the piloting of SMARTdiagnostics, KCF’s high touch engineering team was actively onboarding maintenance personnel when an alarm went off in real-time on a dryer blower.With a quick look at the data and an immediate onsite inspection, it was discovered part of the coupling was missing. Instances like this are where the vision of utilizing real-time data and analytics illuminated the need for adoption across multiple sites.

Through these efforts of workforce enablement and empowering employees with the necessary tools to drive transformation, Prabhu and the Kaneka DX team have rallied over 80 users in KCF’s SMARTdiagnostics platform and Academy learning platform. Collectively, the Kaneka DX team have completed nearly 100 self-study courses advancing their knowledge and supporting their transformation.

Real Impact: From Reactive to Predictive

Shifting to a predictive culture, Kaneka has experienced multiple efficiency gains. One example of an efficiency gain was when the Kaneka team was able to make informed decisions on adding de-foamer (Decanol) to their fermentation process. In the process, foam causes cavitation in the broth recirc pumps while adding foam decreases product quality. Using vibration data, they can determine how to weigh mechanical failure risk with decreased product quality. While an ongoing more complex concept, using data to make informed decisions is contributing to the operational excellence they strive for.

By uncovering issues predictively, Kaneka has experienced better preparation by having replacement parts available and ready during planned downtime. Saving hours of time hunting down the equipment and transporting it if there would have been a catastrophic failure.

One last example is with an evaporation system that was getting a larger volume of vapors causing a pull in condensable vapors. The knockout pot on the discharge was full, meaning there was discharge fighting against resistance causing the rotary vacuum pump to work harder and a high vibration detected. Draining the knockout pot was the recommended action to clear what seemed to be plugged. Utilizing data proactively, the team’s resolution was a design change. Installing a liquid ring vacuum pump in place of a pervious drive screw type pump allowed for a directly driven asset with no gearbox.

Kaneka has documented $1.7M savings directly related to unplanned downtime avoidance, 166 hours of downtime saved, and has built a culture of not just digital transformation but of elevating their workforce utilizing technology.

Cultural Transformation

For Kaneka, cultural transformation wasn’t just an abstract idea; it led to tangible and meaningful outcomes. By fostering a culture of change, Kaneka made a remarkable shift from reactive to predictive maintenance strategies. The infusion of predictive analytics and state-of-the-art machine health solutions revolutionized operations, enhancing efficiency, and significantly reducing downtime.

Another example of moving from reactive to predictive was with their impact modifiers operation. In June of last year, while on a joint call between the Kaneka and KCF Sentry Services team, an alarm was triggered. Sentry Services provided some preliminary and live analysis that the fault was most likely caused by misalignment or a coupling issue. Immediately following the call, the assets was inspected, and a faulty coupling was found. This alert gave the team time to respond proactively.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.