The Problem

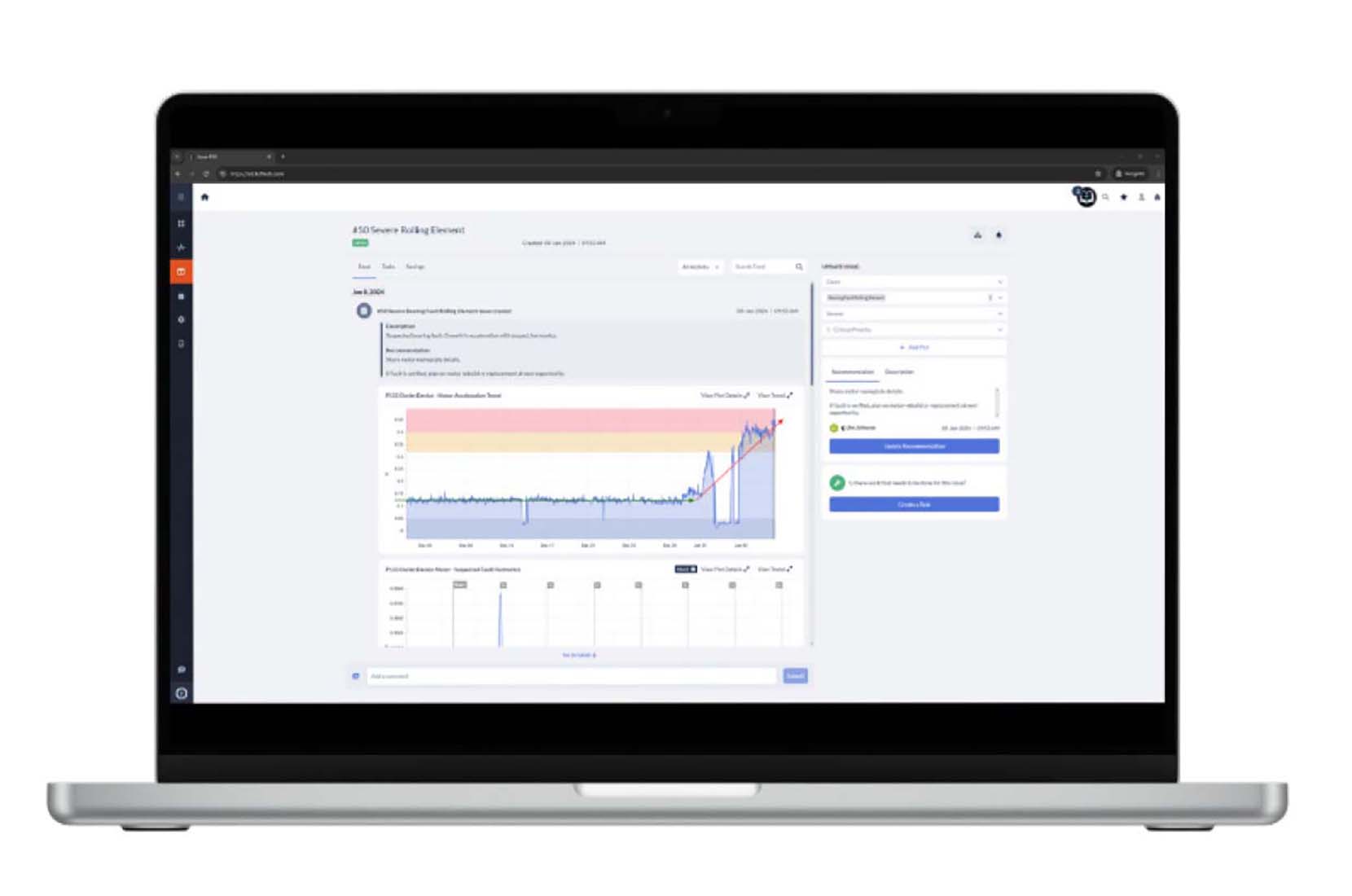

SMARTdiagnostics was showing a high g reading on the arbor outboard reading. A Desk ticket was created, and the plant’s team was contacted about addressing these concerns. Ultimately, low lubrication events were determined to be the issue.

How we solved it

The recommended action was to lubricate as soon as possible, given it was safe to do so. Following this, if the readings remained high, the recommended action was to replace the damaged bearing. However, the readings did reduce after lubrication and the asset returned to normal function.

4 hours

Downtime Avoided

Ready to Take the Next Step in Your Machine Health Journey?

Let’s Get in Touch.Email: [email protected]

Phone: 1 (814) 867-4097 Ext. 1

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.