Introduction

In a 24/7, 365-day operation, mitigating downtime is essential at preventing costly downtime. At Anchor Glass Container Corporation, KCF Technologies’ comprehensive predictive maintenance platform serves as the backbone of operational efficiency. Traditional maintenance methods, which rely on fixed schedules and routine checks, often introduce inefficiencies. Shifting toward data-driven reliability optimizes equipment performance, enhances safety, and reduces unnecessary labor.

The Power of Predictive Monitoring

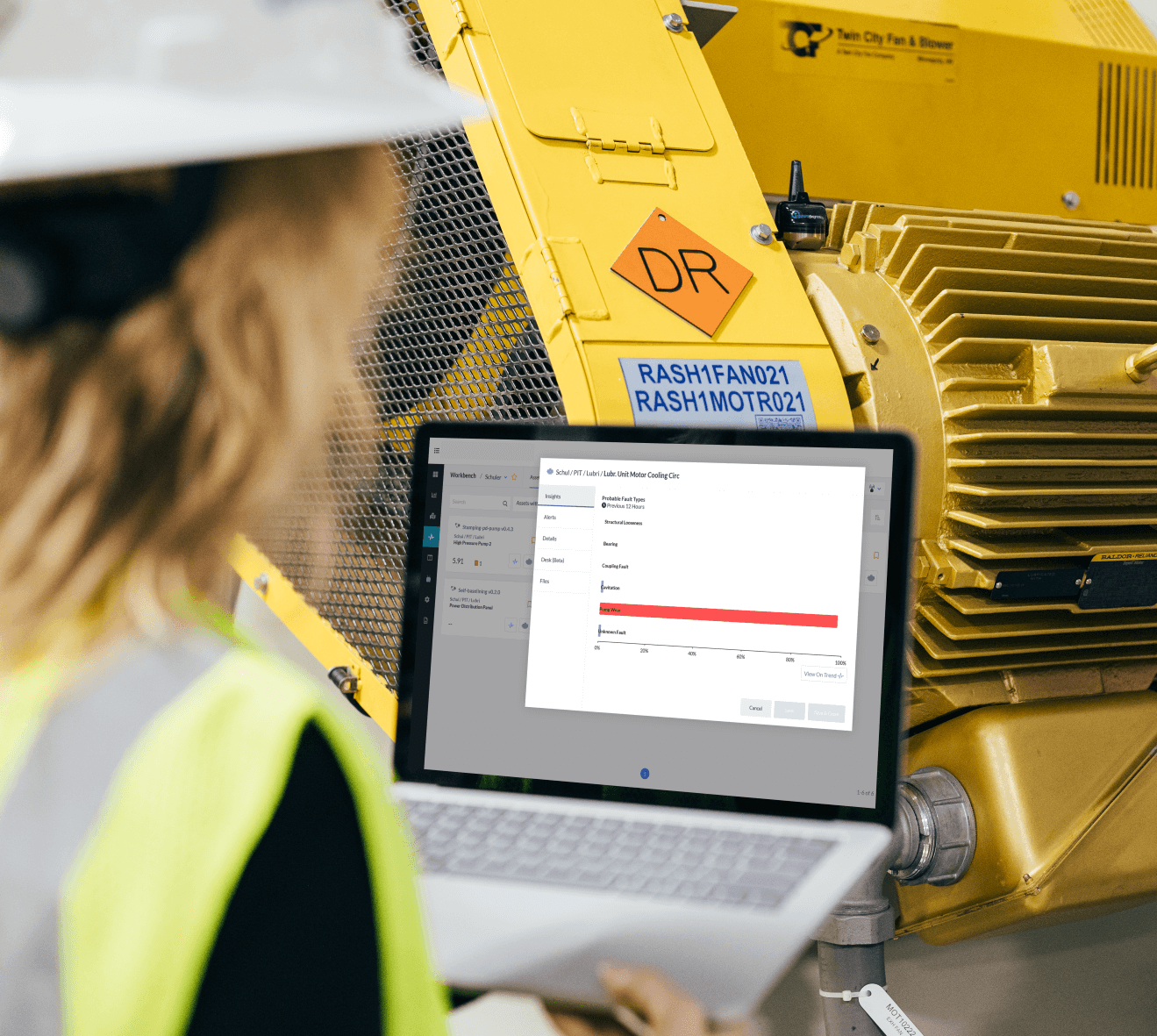

Predictive maintenance introduces a transformative, intelligent approach to maintenance protocols by enabling equipment health data to dictate when servicing is required. Rather than depending on routine routes, sensors placed on the plant’s critical equipment deliver consistent, real-time data.

With predictive monitoring, subtle performance changes become apparent, prompting deeper analysis and a more comprehensive understanding of equipment health. Across Anchor’s five facilities in Oklahoma, Minnesota, Indiana, New York, and Georgia, environmental factors such as temperature and humidity vary significantly which can make traditional monitoring challenging, increasing the value of continuous monitoring. In addition, by comparing data across locations, teams can identify process inefficiencies rather than focusing solely on asset malfunctions to optimize workflows.

In our pilot, there were two distinct saves, avoiding about $200,000 worth of downtime—not to mention the impact on production and recovery time.

Rex Hook

Senior Reliability Manager

Anchor Glass

Real Savings and Operational Efficiency

The benefits of predictive maintenance extend beyond theory—real-world applications have demonstrated substantial savings. In a pilot program, two significant downtime avoidances resulted in an estimated $200,000 in cost avoidance. More importantly, detecting failures early enables planned downtime rather than reactive repairs, which are far more disruptive, costly, and increases the chance of workplace injuries.

A New Era of Maintenance

As the industry evolves, so does the workforce. While experienced employees with decades of knowledge are transitioning out, the next generation of workers, though equally inquisitive, can elevate their knowledge faster by augmenting their daily work with advanced technologies. Predictive maintenance supports this shift by fostering a proactive rather than reactive approach, while also providing a platform for accessing and tracking historical data.

The key to long-term operational success is understanding and responding to equipment needs before failures occur. By shifting to predictive maintenance, manufacturers can minimize downtime, improve efficiency, and create safer work environments. As technology continues to evolve, integrating data-driven insights with hands-on expertise will be essential for staying competitive. The future of maintenance isn’t just about fixing problems—it’s about preventing them.

KCF Full Guide

Learn more about gaining a competitive edge with the most advanced, comprehensive machine health optimization platform.